Today we have a roundup of things loosely connected to home gunsmithing and new technologies: what folks are printing, a well-deserved award for a free radical, an amazing bit of nonsense at a gun range, and general additive technology news including a reasonably-priced 3D scanner, reasonably priced modeling instruction, a power grab by the Librarian of Congress (what’s in the water in Washington?), a DIY (partly printed) rail gun, and desktop 5-axis CNC.

People are Printing…

That’s a FOSSCAD Hermes lower, assembled into a very nice AR with an equally home-grown (although not 3D-printed) suppressor with a stainless-steel core and titanium alloy tube. Homegrown, but decidedly not low tech.

Ah, but can it shoot?

So far so good. 250 rounds downrange.

So far so good. 250 rounds downrange.

How about some practical accessories? A lot of 3D-printing gunnies start with grips. Here are a couple with a twist.

The Punisher! A bit gaudy for our taste, but de gustibus non disputandum est, eh? It’s interesting how the layers of 3D printing (set up for a pretty coarse, therefore rapid, print) resemble wood grain.

The Punisher! A bit gaudy for our taste, but de gustibus non disputandum est, eh? It’s interesting how the layers of 3D printing (set up for a pretty coarse, therefore rapid, print) resemble wood grain.

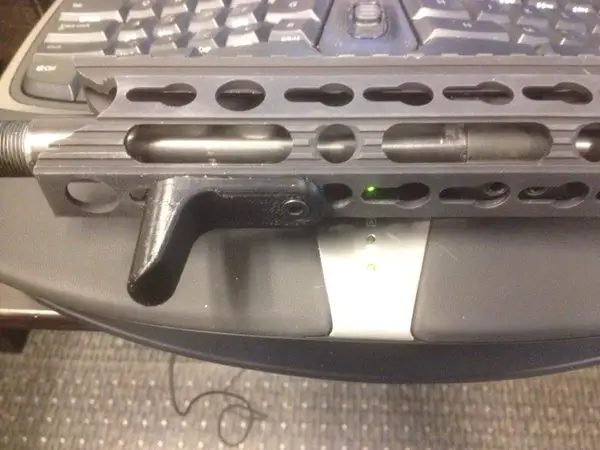

This one’s an MOE styled grip printed in Laywood material — filament containing actual wood fibers. It feels “wooden.” It looks different. The next is probably one of the most practical simple prints a beginner can do (although the files are not released yet).

It’s a hand stop for a Keymod handguard/rail system.

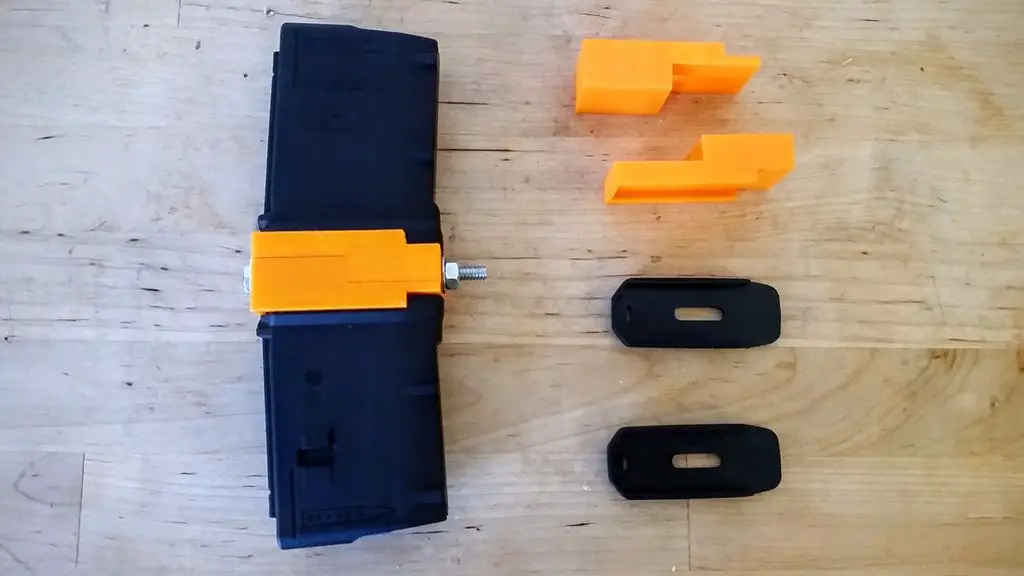

The next print is something you hope you don’t need… because it means your state went Full Retard. It’s a mag coupler for joining two 10-round magazine base to base, for a legal flip-to-reload 2 x 10 round unit. If you’re stuck in Cuomostan…

Here it is in place, in a ban-state AR. (On, naturally, a ban-state legal AR). Is there nothing the AR cannot do? Well, there are many things it can do, including making ban-happy politicians’ brain waves go nonlinear.

Bill of Rights Award for Cody Wilson

From the Citizen’s Committee fpr the Right to Keep and Bear Arms, and the 2nd Amendment Foundation. Wilson’s reply:

My thanks to @CCRKBA and @2AFDN for this award. I’ll always fight for the battle rifle and for free men worldwide. pic.twitter.com/GTHQKRktc8

— Cody R. Wilson (@Radomysisky) October 26, 2015

Ignorance of the Law is No Excuse

But some Jobsworth at his local range managed to eject 3D-printed firearms enthusiast ArmaDelite for not violating the Undetectable Firearms Act, anyway. He responded, with the text of the law.

Kicked out of range w/ Aliamanu-Phobos misquoting UFA. Receiver/frame is NOT firearm in UFA. @fosscad #3dprinting pic.twitter.com/RNWA4aF1ey

— ArmaDelite FOSSCAD (@ArmaDelite) October 27, 2015

Meanwhile, we have found a use for the officials and workers of the Transportation Security Administration, who worry about undetectable firearms while their mouth-breathing “security officers” miss detectable firearms in tests. (Not all of them… they just miss 95% of them). We’ve discovered that they’re useful for checking if the floor is level: they drool out of both corners of their mouths!

Smartphone Hosted 3D Scanner

It wouldn’t be a 3D roundup without something on Kickstarter, and this time, it’s this wazoo new 3D Scanner from Australia, mate, that attaches to your smartphone, and exploit’s the phones chipset and I/O.

The Eora 3D Scanner doesn’t have a lot of applications we can see to weapons work, not even to reverse engineering (although its claimed specs are better than any other consumer priced 3d scanner). It’s just pretty neat technology. Check out the bluetooth-connected turntable. It’s also interesting how they’re manufacturing it, from precision-machined 6061 extrusions. Who has some good ideas on how to apply it?

Want to learn to model?

We missed out on this when it was on Kickstarter, but HoneyPoint3D has an excellent course of tutorials that work with Autodesk’s free (as in beer) Meshmixer software.

They also have a two-hour overview of 3D printing for $20.

Is it Against The Law to use Your Own Filament?

Another office that wants to regulate 3D printing, the Librarian of Congress (who died and made her Queen?), says: it depends. A recent opinion caused by Stratasys’s desire to not only lock people into its overpriced, underperforming filaments, but to control what they print with Stratasys (or Makerbot) printers, says resoundingly that if you own the printer, you can put your own filament in it.

That is, unless you want to print something that might be regulated, somewhere. You know, like gun parts — which Stratasys, all-in for gun control, doesn’t want you to print.

Yes, this is totally irrational, not to mention borderline National Socialism, but you say that like it’s a bad thing. Stratasys and Makerbot execs, not to mention DC bureaucrats, think having control of your prototyping is a good thing. Because they’re not like the little people.

Peasant.

Michael Weinberg has tried to make sense out of this ruling. If he hasn’t succeeded, it may be because thee just isn’t a lot of sense there to be had.

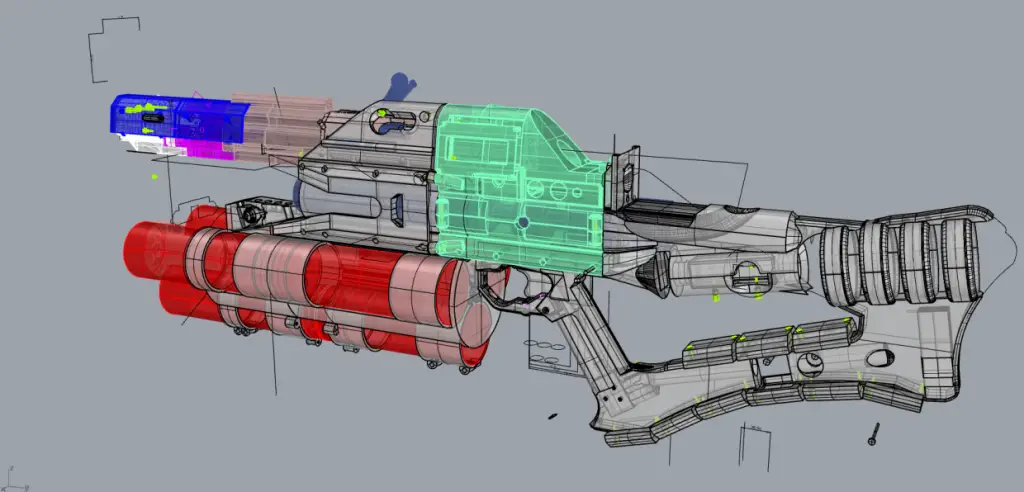

Plasma DIY Railgun

This homebuilt railgun was in the news recently. Make Magazine has a nice run-down on it and its creator. He had to solve all the same problems that big aerospace and defense prime contractors who have worked with this tech have done, but he did it on a beer budget. The inventor, David Wirth, is a bit diffident about the whole “gun” thing, but his ambition is notable, even if his idea of range safety is a bit on the weak side. The unstable projectiles dissipate their energy very rapidly, fortunately.

It looks like Wirth, a UCLA MS/BS in Aerospace Engineering, is moving on (to metal 3D printing) after demonstrating proof of concept. “I love the feeling you get when you’re the first person to do something,” he confessed to Make’s Gareth Branwyn.

His gun, the Wirth Experimental Portable Railgun Version 1 (there probably won’t be a 2) uses two machined rails and a very high voltage from an array of high-voltage capacitors to fire small, unstabilized conductive projectiles.

This latest video — posted a couple days ago — has so many failed attempts to launch a teflon (PTFE polypropylene) slug (with a conductive, sacrificial copper ring that’s supposed to form plasma) that the experimental nature of the project is never in doubt.

If you watch all the videos, you can see that many of the components are 3D printed. Previous tests of the railgun have fired various projectiles — and temporarily fried the Arduino control board with electromagnetic pulse. (It recovered, suggesting our homemade gadgets will survive the attack of Skynet).

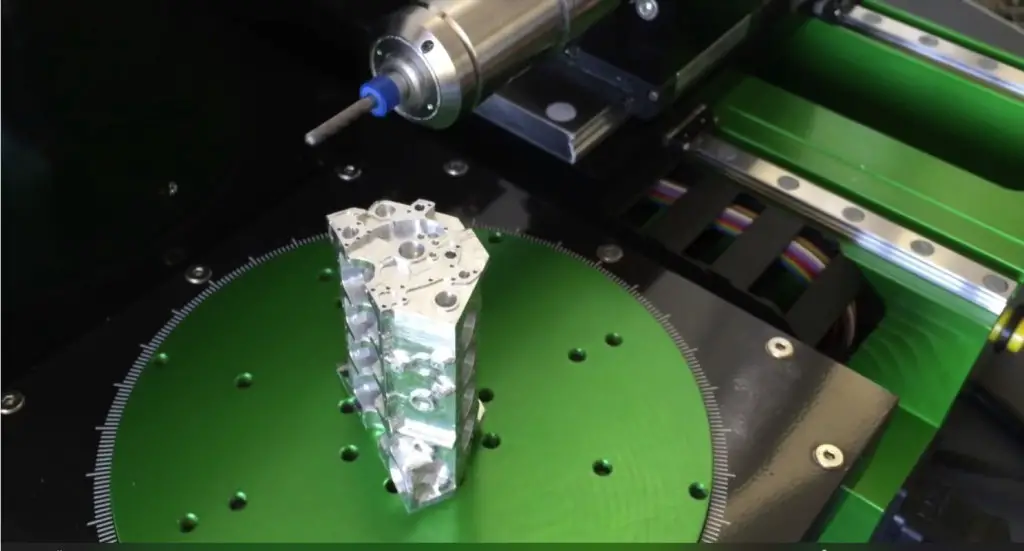

5-Axis Desktop CNC

Here’s a post that promises a 5-axis CNC for $5k. We investigated at the machine’s actual website and its Kickstarter page, and we found (1) like Cody Wilson and DefCAD, they found CNC to be less than a slam dunk, and (2) unlike the GhostGunner, this is going to be really limited in size, power and rigidity. If you have parts to make of aluminum that are smaller than about four inches in any dimension, this tool might work for you, or just as a way to learn multiaxial CNC.

The V8 block is an impressive demonstration of the unit’s capabilities. It’s also about the size of your big toe.

It’s interesting that the parts for these little CNCs ate made on honking big CNCs, so the knowledge transfer initially went the other way!

Thinking about it overnight, we woke to the realization that the sweet spot for this thing might not be in cutting jewel-like aluminum pieces at all, but in making wax patterns for investment-cast short-run parts or prototypes. We still like 3DP better as a production way of doing that — 3D Systems makes a printer especially printing wax, and Pinetree (one of Ruger’s casting subsidiaries, or some similar corporate relationship) installed at least two of them last year.

Correction & Update

Correction: Due to an editing error, the end of the last sentence was cut off originally. It has been restored.

Update: in the light of Tam’s comments below, this short video, received just today from 3DPlatform.com, makers of the 1-meter-square-by-50-cm-high-build area 3DP1000, seems to be on target.

Boo!

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

10 thoughts on “Printing, Scanning, Milling, Making: Oct 2015 Update”

“The V8 block is an impressive demonstration of the unit’s capabilities. It’s also about the size of your big toe.”

Never before have I lusted so irrationally after an object with no conceivable use.

The engine block, or the 5-axis nano-mill?

Wait! I know! That would be The Coolest Key Fob On The Planet.

That 3D scanner could be used as a comparator for your super precision hand loads, check concentricity of bullet to case, scan a cast of a chamber and throat?

The wax investment pattern idea is awesome. Thats what I liked about the 3D solid modeling machines. But they don’t model in wax. I can think of a hundred contemporary maker items be cool to be able to cast. Easy to punch in the shrink allowances, gates,risers, chills, cores and spruces too. And with 5 axis’ you can make some really baroque things. No need for maxing pattern molds and casting patterns, or the wear and tear on those molds, you get to change any feature on the pattern as needed.

Is it true five axis though, or that early pseudo 5 axis?

Don’t understood the whole butt-to-butt magazine duplex. The movement is awkward and you’re asking to put your reload ammo into the mud, the blood and the beer. If you’re gonna duplex (and you certainly should in a ban state) keep the mags right-side-up.

The ban-state AR is a thing of beauty and I do hope hoplophobes everywhere are feeling what passes for their brains flowing out of their ears.

I agree about the butt to butt thing.

As a young soldier on an exercise I did that with some duct tape thinking it was a neat idea. One of the instructors that day was an ex SAS Vietnam veteran who explained in great and emphatic detail how I would grind the bottom mag in the dirt when I flung myself to the ground, filling it with crap and screwing the feed lips, leaving myself defenceless and then dead.

This happened about 30 years ago, and I still vividly remember that particular minute of instruction. 🙂

***Don’t understood the whole butt-to-butt magazine duplex.***

Easy. Some magazines, like the AK, Galil, British L1A1 *inch-pattern* FAL mags, Bren magazines and others that use the *rock and lock* reloading cycle have a very prominent magazine pivot lug that catches if it’s placed with that end down in a magazine pouch, pocket or sidebag carrier. Others, like the Euro FAL magazines, M14, BAR and others [and, of course the M16/A1/A2/M4] have no such lug and can happily roll in and out of both mag well and carrier.

Even in the day of the M2 carbine 30-round curved magazine going end-to-end was more common than side-by side. The availability of oversize magazine pouches that can accommodate the double-mag assemblage can sometimes be the reason for that, as can that somebody just wants twice the usual capacity in some *grab and go* or initial contact situations [tankers, sometimes] and the possibility of having two pivot lugs side-by-side doubles the opportunity for the lug to catch on the carry bag [Claymore bags, engineer pouches, AFIK bags and gas mask bags, as well as The Other Guy’s Stuff have all been used at times] especially if a trousers or jacket pocket is so utilized.

On the other hand, having a dual mag with the lug sticking out taped end-to-end guarantees that at least one of those little buttons will be out there to catch on somethin’. It’s usually an individual choice unless prohibited by edict, in which case the edicter will eat the blame for some guy found dead with an empty weapon. In Afghanistan the Russian kontraktniki very often ran a pair of 45-round RPK74 mags end-to-end [known as a *royal mag* to Russian grunts] because the deep pocket 3-cell 30-round AK74 mag pouches were so good about catching on the lug if placed inside rounds down. So up it was, and a guy riding atop a moving BMP or BTM needed all the spray rounds he could get away with until he hit the greound and could really shoot.

So it’s really a 2-part answer: do your mags slide in and out of your pouches slick as butter, and do you have enough pouches? And is an extra mag’s worth of ready rounds more important than a telescopic sight/ dotscope/ bayonet/ grenade/ other goodie? Ask those with different experiences, and you’ll get differing answers.

3d printers can use PVA filament, which is soluable in hot water.

A unique ballistic research blog. One section, on wounding provides graphic photographic field evidence along with recounts of rounds used and bullet types. Lots of other data. Well done.

http://www.ballisticstudies.com

I think you really have something with wax pattern idea. Making things to make other things is something the 3D printer and mini cnc crowd don’t talk about much.

Also on the subject of base to base magazine couplers, Ruger 10/22 shooters actually use them a lot, because the rotary magazines feed more reliably and a 2 or 3 rotary mag set up actually protrudes less than a 25 round box magazine. That said, they are mostly using them on ranges so mud in the feed lips is less of a problem.