Category Archives: GunTech

In 1959, a General Motors executive boasted that there were so many options available to buyers of the 1959 Chevrolet, that it was theoretically possible for no two of the hundreds of thousands of Chevies delivered that year to be alike. (In fact, many popular configurations were made in vast quantity, and many theoretical combinations of options made no practical sense and were never built). It’s quite a difference from today, when you have red, white, black, silver, and Option Package A or Option Package B. The new way of doing things substitutes soulless modern efficiency for funky 20th-Century soul.

In 1959, a General Motors executive boasted that there were so many options available to buyers of the 1959 Chevrolet, that it was theoretically possible for no two of the hundreds of thousands of Chevies delivered that year to be alike. (In fact, many popular configurations were made in vast quantity, and many theoretical combinations of options made no practical sense and were never built). It’s quite a difference from today, when you have red, white, black, silver, and Option Package A or Option Package B. The new way of doing things substitutes soulless modern efficiency for funky 20th-Century soul.

Sometimes it seems like there are more ways to customize an AR type carbine than there were for that ’59 Chevy buyer. Oddly enough, the AR and the ’59 Chev are near-contemporaries, too; but initially, there was nothing but factory standard parts for the rifle. The military was offered an evolutionary/revolutionary CAR-15 “system” with submachine-gun, rifle, carbine, and LMG versions, and apart from 10,000 SMGs for special purpose units, they didn’t buy. Civilians could buy a Colt SP1 Sporter until the 1980s, when they got the option of a CAR-15 inspired SP1 Carbine, and they could customize either only with surplus parts or knockoffs of them.

The first real mods that tried to extend the gun came in the 1970s, with things like the Rhino gas piston conversion, and the 6x45mm round. Both are forgotten now, but led the way for many subsequent attempts to pistonize the AR and to fit it with alternative components. That was 40 years ago. The AR is now recognized not as a single rifle or even as a CAR-15-style “family” but as a highly modular shelf full of

Now, there are so many new AR parts all the time there’s even a website devoted to the announcements, AR15News.com. A quick look at the parts being promoted there suggests that even today, add-on parts fall into two categories:

Now, there are so many new AR parts all the time there’s even a website devoted to the announcements, AR15News.com. A quick look at the parts being promoted there suggests that even today, add-on parts fall into two categories:

- Personalizations that modify the gun in a way that pleases its owner; and

- Modifications that are meant to change the basic function of the gun.

Here’s an example of the former: the DS Arms “bufferloc” kit. (And here’s it’s press release on the aforementioned AR15News). It claims a number of benefits, but the one we see as real is that a nose-heavy upper doesn’t swing sharply open when the rear pin is pushed out. This is a minor aggravation, but a real one. Some of the other claims seem to use to either be (1) theoretical, not data-based’ and (2) beneficial only if the gun is not made right in the first place. (For example, they claim to prevent carrier tilt, something that’s not a problem in ordinary direct impingement ARs, if they’re built to spec).

We don’t mean to bag on DSA. They’ve been around for a while, and build some high-quality products. We can vouch for their RPDs and FALs, for instance. But their latest accessory got us thinking about accessories, period.

Accessories: everybody loves ’em. AR gadgets are to guys (and some gals) like high heels are to many other gals’ closets (and some guys’, probably; it’s a free country, but we really don’t want to know). Gun folk no more explain to shoe folk the difference between our AR uppers than they can explain the difference between this year’s and last year’s Manolos.

If you want an accessory, by all means get it, and try it out. If it’s your gun, you only use it by yourself, and it makes you happy, that’s the only criterion you need to meet. But if you work with a team, or if you’re buying for a department, unit or agency, there are a number of reasons to go slow on buying cool AR stuff.

- Uniformity of weapons has its benefits. If one of you is out of the fight, perhaps because he’s wounded, performing a specialty task (medic, breacher) or communicating with higher, interoperability of weapons with the shooters actually shooting means the non-fighting guy’s guns and ammo become a potential New York reload for the fighting guy. (One combat duty of NCOs in the US forces is accountability and cross-leveling of weapons and ammo). There is no feeling so stupid as holding a strange gun and looking at a strange optic, unsure which button turns the illuminated reticle on (and worse, what turns it on on the NVG setting as opposed to the one that lights up your face for the enemy).

- Personalization limits resale appeal. While you can sell a generic M4 knockoff to anyone looking for a generic AR, your potential buyer pool shrinks with each add-on, proportional to the distance of that add-on from the norm. Fewer buyers = less demand = less support for a premium price. Paradoxically, spending thousands to accessorize a gun may decrease the prospects, and economics, of selling it.

- Accessories never add their own value to a gun. It’s strange the way that works, but a $2,000 AR with $2,000 in premium accessories changes hands for $2,100 all the time. A $1,500 gun with a $100 ambi selector and a $300 drop-in match trigger is a $1,500 gun. You’re never going to get the price of that Larue mount for your ACOG back. So do you buy the Larue or stick with the factory two-knob job? Depends. If your mission means optics are on-again, off-again, you’re going to love the Larue. If you set-it-and-forget-it (for instance, if you use other NODS tandem with the ACOG, and don’t have to swap on and off), then the Larue is of small benefit to you.

- Odd calibers make great stories, but we’ve learned some things from the 2012-13 ammo shortage. In a panic, common calibers disappear first as hoarders grab them. But much larger quantities of common calibers are kept on hand. At the peak of the empty-shelves period, the oddball rounds that were available varied widely from one shop to another. In one geographical area, you could still find .300 Blackout and 6.8 SPC; in another, you could find no “near-military” calibers like that, but only hunting ammo for such rounds as .243 Winchester. An odd caliber is, unless you’re standardizing it across an agency, a permanent supply and interoperability problem.

So can we boil it down to one pithy phrase? As it happens, we can. For “hobby” ARs, suit yourself. For combat-oriented ARs, figure out where the center of the unit/team/market is, and deviate from that point only after careful consideration.

If you are that guy who wants to run an EOTech when everyone else is running an Aimpoint, that’s OK, but it’s on you to make sure the other guys are comfortable with your holographic sight — and that you have spare batteries at hand. An illuminated optic that isn’t subject to frequent preventive-maintenance inspections is nothing but a device for storing dead batteries.

3D Printing in Metal, What’s New?

Last year we saw several developments that hinted that 3-D printing was coming in metals. Of course metal 3-D printing is fairly common now, using various modes of laser sintering, but the promise of 2014 was that consumer level (or at least prosumer) 3D printing in structural metals was a possibility.

And that’s where it was as 2015 dawned: “possibility”. Three big shakers of 2014 were:

- A team at the Sustainability Lab at Michigan Technical University, using a Rostock based deltabot to deposit material from a welder;

- A company called Weld3D which meant to commercialize technology similar to MTU’s; and,

- a student project at the Technical University at Delft, Netherlands, which combined a RepRap Prusa mechanism and software with a MIG welder;

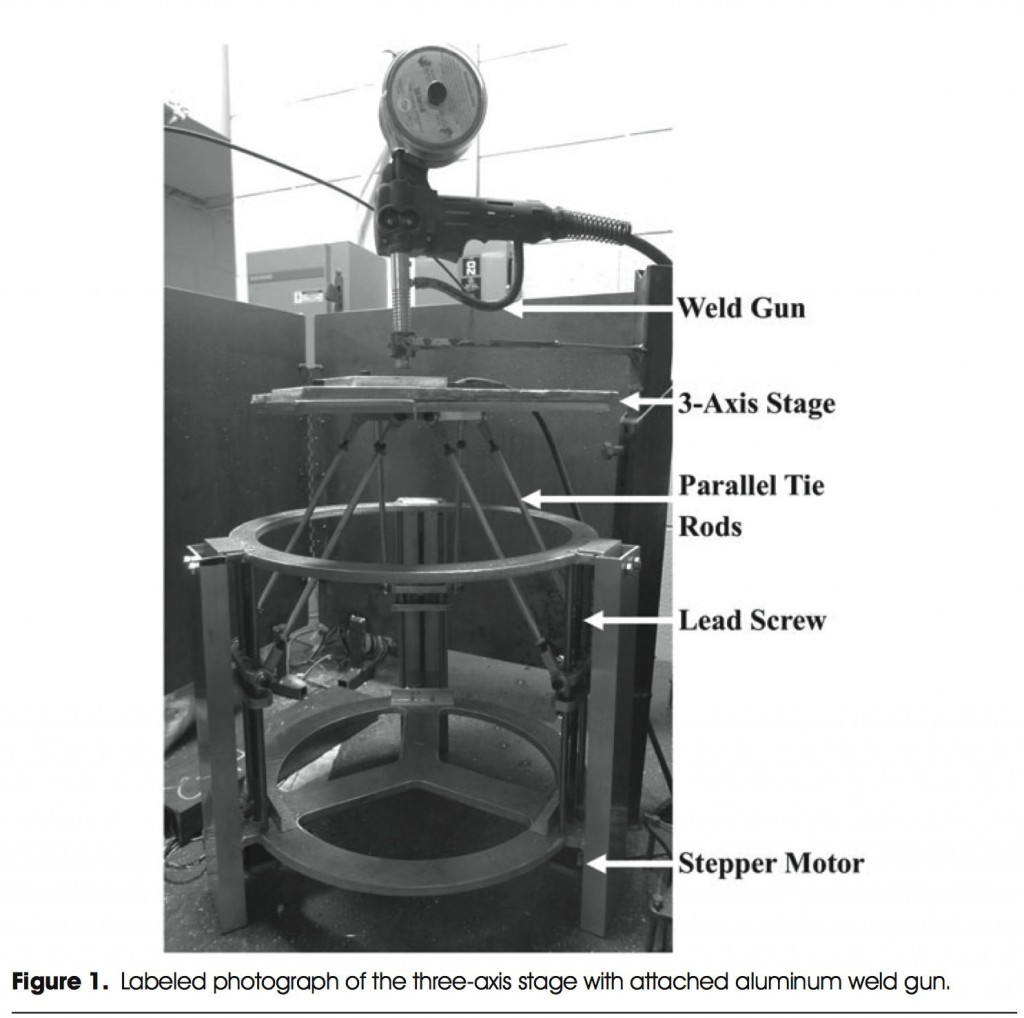

The MTU inverted Rostock deltabot system. Fixes the heavy weld gun in place, moves the work platform. Click to enlarge.

The TU-Delft project is on hold, pending a new intake of undergrads to play with it and perhaps take it in a new direction. It never proceeded beyond printing a few homely and ragged walls, but it was a proof of concept.

The Weld3D project shows no signs of change at its website. We’ve messaged them for information, and we’ll share what we can.

And that leaves the MTU project, which has a new paper in the December 3D Printing and Additive Manufacturing (which they just emailed us about this week). In this paper, they’re dealing with the issue of “substrate” — the plate that they print upon, in their design, a metal plate.

As everyone who’s done 3D printing with basic plastic Fused Deposition Modeling (FDM) processes knows, the base you print upon is vital. Some materials stick to some bases, and your print gets destroyed when you try to removed it. Others don’t stick, and the corners curl up, leading to the same ultimate result — a scrap print.

As you might imagine, inert-gas metal-arc additive manufacturing is just as sensitive to substrate as common ABS and PLA printing is. A major problem is burning through the substrate; another is, as you might expect from a welding-based solution, adhering to it. (You want the layers of your metal part welded to each other, not to your 3D printer, right?)

In this experiment, Amberlee Haselhun and six collaborators from the Michigan Technical University Materials Science and EE/CE Engineering departments examined how to make weld-manufactured aluminum parts not stick to their substrate, and found a best-possible and most-economical possible solution. Additionally, these solutions are fully in keeping with the Sustainability Lab’s devotion to manufacturing technologies that can be employed with minimal demands on infrastructure and minimal environmental disruption.

Gold in the Introduction

Before we get to the experiment and its conclusions, we should mention the brilliant, concise introduction, which breaks down “3D Metal Printing” by commercialized technology (numbering of list ours, and citations deleted):

3D metal printing is commercially available in several forms:

- laser-based additive manufacturing,

- weld-based additive manufacturing, and

- shape deposition modeling.

Laser-based additive manufacturing methods include powder bed fusion (direct metal laser sintering), selective laser sintering, selective laser melting, and directed energy deposition (laser cladding).These methods offer excellent dimensional control but have large production costs due to the use of lasers or metal powders.

And then introduces a taxonomy of weld-based (and potentially lower-cost) additive manufacturing.

Weld-based additive manufacturing methods include gas metal arc welding (GMAW), gas tungsten arc welding, directed energy deposition and powder bed fusion (electron beam melting), electron beam freeform fabrication, and microwelding in a single-layer multipass welding regime. Parts produced by weld-based additive manufacturing are inexpensive and nonporous with good interlayer adhesion, but have a limited print resolution and poor surface finish. Microwelding is the exception, exhibiting excellent dimensional control and finer surface finish resulting from the small-diameter electrode and wire employed.

(Hmmm. We’ll have to look into this microwelding juju). Note that what they call GMAW, welders call MIG welding, and what they call “gas tungesten arc” is commonly called TIG welding. If everybody could speak the lingo, it wouldn’t be grad school, eh.

The introduction then notes that, “Shape deposition manufacturing processes feature both additive and subtractive manufacturing.” We’d note that Weld3D’s rocket nozzle proof-of concept seems to be this sort of part, having been rough-formed by weld-based additive manufacturing, and then turned to final size, shape and finish (at least, on the outside). While the inside of the part they have shown was not (yet?) turned or finished, one can clearly see that this is a potential method for making a de Laval type rocket nozzle with considerably less waste than milling from billet would produce.

The Experiment

The MTU printer’s current iteration is based on an inverted Rostock Deltabot, with a more solid frame moving the work platform under a gas metal arc welding (GMAW) weld gun fixed in 3-dimensional space. (In a normal Rostock, the print head moves and the work platform stands still. This one is inverted because of the weight and inertia of the print head — the heavy Spoolmate 100 weld gun).

In the experiment they used 0.030″ 1100 aluminum welding wire and laid down a simple block of aluminum on two different materials with three different coatings each. The materials were 1100 aluminum and A36 steel. 1100 is almost pure aluminum — 99% pure, minimum, and it is the strongest commercially pure alloy: it’s highly conductive, extremely corrosion resistant, and easily worked. It won’t take heat-treatment and is not much used in structural applications. Conversely, A36 is a common structural steel, often used in I-beams and building frames and that sort of thing.

Each substrate material was tested bare, with an 18.8 µm aluminum oxide coating, and a spray-on boron nitride coating.

Conclusions? The graphic shows the essence of it. The steel substrate was better than the aluminum across the board; the boron nitride was the best coating, but bare steel works OK.

Solving the substrate-adhesion problem — not just for 1100, but for all materials we want to print — is just one of many small steps that must be taken before you can plug something into your USB port and print a hammer (or a Yoda head) in metal. (That printed R2D2s and Yodas are essential sample prints on everybody’s websites says something about the lonely lives of engineers and scientists, eh?)

What Else is in the December 3DP?

The current issue also has several other interesting articles, including a history of National Science Foundation support for the development of this technology, and some preliminary plans for how one might 3D print objects made of more than one material (analogous to using inserts in cast or injection-molded parts). Unfortunately these articles are only available to subscribers (very expensive) or by paying the rather stiff rates ($474!) for access. Editor Hod Lipson has done an excellent job of finding and publishing worthwhile technical articles, but the economics of academic publishing (low volume, high costs) means that most of the people who would benefit from this knowledge struggle to get at it.

Still, there’s nothing like progress, which for us means less silly slogans shouted by silly politicians, and more, the strides made by scientists and engineers.

Soviet ATGMs and October, 1973 (Long)

So far in this series, we’ve looked at the development of US and Western European anti-tank guided missiles, from their origins in a German WWII design program to their introduction to combat — just in time to encounter Russian missiles designed along similar lines — in the Vietnam War. (The Russian missiles got the first kill, by a couple of weeks). Today we’ll extend the story of early ATGMs by discussing how the Russians developed their missiles, and how Russian missiles figured in Arab planning for in the Yom Kippur War (the Ramadan War, to the Arabs, and the October War to the strictly neutral) of 1973. Unlike the Vietnam offensive of 1972, where they were only locally decisive, the robotic tank-killers decided battles and nearly won the war. We’ll have more about the war in a future installment (this one is already over 2500 words — oversized for a web post).

AT-3 Sagger (this one an improved Chinese copy with a much larger, stabilized sight and SACLOS guidance).

Russian Missile Development

Compared to Germany, which was working on them in 1945, and France and the USA, which were in development from the earliest 1950s, the Soviets were a little late to wire-guided ATGM development, beginning only in the late 1950s. It’s unknown whether they had as a basis any foreign technology. Certainly they could have used captured German technology, French or American technology acquired by espionage, or they simply could have applied robust Russian engineering to problem solutions that they knew their Western rivals had already accomplished. It’s probable that all three were part of missile R&D, with the heavy lifting being done by Russian engineers. The Russian product, by 1973, was a missile that was combat-ready and had several advantages over its Western counterparts.

As with SAMs, Russian engineers passed through numerous experimental iterations of ATGMs (Anti Tank Guided Missiles), and they delivered to their Arab friends the first and third version that they operationalized. The first missile was a bit of a turkey; fired from a converted GAZ-69 jeep, the 3M6 Shmel (NATO coded, AT-1 Snapper) flew fairly slowly, had an enormous launch signature, and was vulnerable to the obvious countermeasure of blowing away the jeep and its crew, including the missile aimer who could not fire from a remote or dismounted position, but sat in a seat facing backwards looking at the target through a periscopic sight. The gunner had to continue to aim at the tank and steer the missile throughout its flight, which could be 15-20 seconds — a lifetime, literally, in armored combat.

It is very hazardous being on a tank battlefield wearing less than a tank. A cotton Army shirt, or a sheet-metal jeep, provide no protection and if that’s what you have, cover and concealment are vital. The Snapper couldn’t be fired from cover (except in its BRDM version, which put a bare 15mm of armor between the operators and the great outdoors), and it negated its own concealment by launching from the control station.

The third missile, though, the 9M14 Malyutka, better known by its NATO reporting code AT-3 Sagger, was a hit, no pun intended. The Sagger, while having a great resemblance to the French missiles the Israelis had played with and a family resemblance to the Snapper, was small. It came packed in a plastic “suitcase” half of which served as the base for its simple rail launcher, and the other half as a base for its reusable sight. One man could carry one all day on his back, and two, suitcase-style, in his hands for short spurts. In true Russian tradition, the missile was sturdy and reliable, and made no superhuman demands on its operator. True, it was a MCLOS (Manual Command to Line of Sight) missile, at least in these early versions, and operator training was vital, but along with the missiles, the Soviets had developed operator and maintenance training, including mobile missile simulators that could travel with divisional logistics elements and keep operators sharp. These they furnished freely to the Egyptian and Syrian armed forces (among others). It was the Egyptians who would make the best use of these missiles.

The Sagger and the Tank Sack

Soviet doctrine had long taught the anti-tank ambush under various terms (the image-rich “tank sack” is one that springs to mind), and they’d used it deftly against the Germans, whose armored warfare worked splendidly against Russian tanks, and not so well against concealed AT guns attacking the Panzers’ vulnerable flanks.

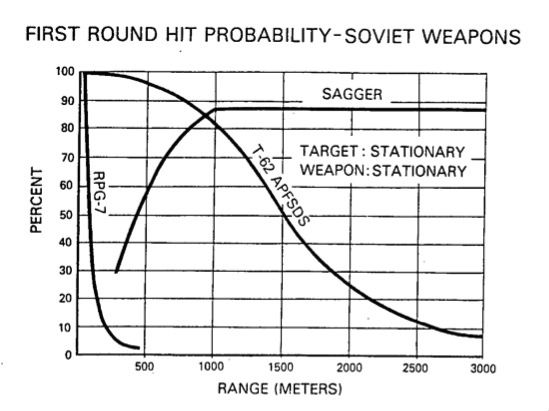

The modern variation of the use of AT guns was to follow leading tanks closely with infantry antitank teams. Soviet tanks would have their flanks guarded by infantry, something comforting for any tanker, but these infantry would be well-equipped with AT weapons, principally long-range Saggers and short-range RPGs. A Sagger crewman needed intensive initial and recurrent training, and the Russians developed an innovative series of portable simulators to keep their missileers sharp without expending vast quantities of costly missiles. The well-trained Sagger crews dug in and/or located on reverse slopes, with their missiles displaced to the limit of their cords (about 15m) and only their periscopes showing. This protected them better than their unlucky mates in the Snapper jeeps.

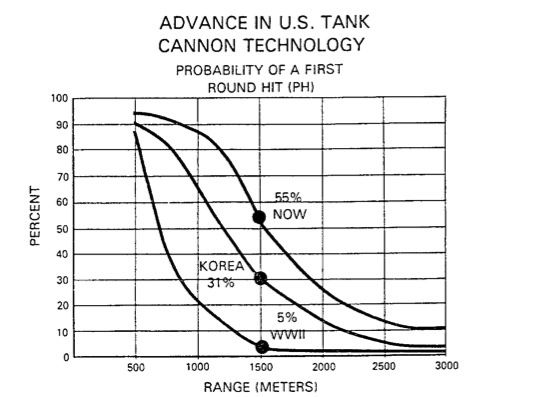

The Soviet-designed weapons had a minimum effective range, but more to the point their maximum effective range was 3,000 meters, on the ragged edge of the effective range of the West’s 105mm tank gun. Moreover, a tank gun’s accuracy against a moving target depends on accurately ranging and leading the target, and so, a tank gun’s accuracy declines with range, and declines precipitously with range on fast-moving targets. This period US chart NOTE 2 brags up the improvement in a pH from Sherman to Pershing to M60A1 days:

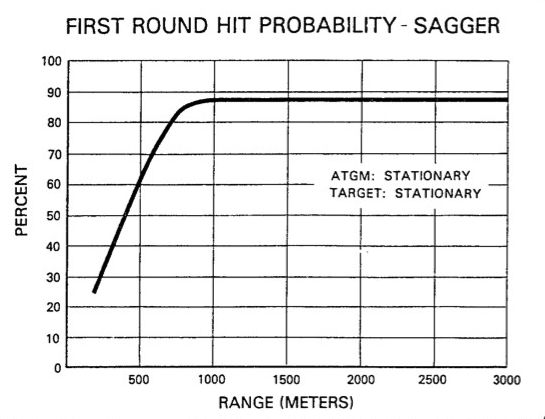

But a missile under human guidance, like the Sagger, can track a moving target even if the target changes direction or speed. The general rule of thumb is that the first hit decides a tank fight; Sagger had a near 90% probability of hit at all ranges from 1,000 to 3,000 meters.

A hit gave the Sagger a very high pK as well: the warhead was among the most effective in the world at the time, penetrating the equivalent of 17″ of rolled homogeneous armor at 0º obliquity (engineering speak for “square on”). US testing of captured Saggers and computer probability analyses assigned the Sagger a .67 pK at a mean engagement range of 2,500 meters.

Combined with the T-62’s 5000+ fps tank guns for the midrange and RPGs for the knife fight, the Sagger meant a Soviet-style (including Egyptian or Syrian) antitank ambush was potentially lethal from 3,000 meters to zero.

American soldiers and engineers were very impressed with that graph.

Soviet technology made the combined arms army of 1970 very different from the victorious horde of 1945, Unlike the Western Allies, who had advanced under an umbrella of air power, the Soviets chose not to depend on their powerful Air Forces and Frontal Aviation, but to give their tank and motorized rifle units an umbrella of surface-to-air missiles overhead and a screen of anti-tank missiles to the front. They equipped every tank with night vision, choosing to spend now on active infrared rather than wait for the costs of image intensification to come down (the West, mostly, made the other choice, to delay purchases now and skip a generation of night equipment). This would also shock Israel, when her enemies (especially the Syrians, who had trained with the night sights and lights very extensively) could see at night, and their army could not. The IDF was heir to a tradition of night-fighting from 1948, and its leaders firmly believed that Arabs were too frightened and superstitious to fight at night, just as they believed that Arabs couldn’t operate and maintain sophisticated missiles.

The Sagger Countermeasures of 1973

Before the war, the Israelis didn’t take the Sagger seriously. They knew about it from desultory US reports and from occasional firings during Suez skirmishes — inconsequential firings that encouraged them to disrespect the missile. It was just one more anti-tank weapon, and when their own forces wanted anti-tank weapons, the Deputy Chief of Staff told them, “You already have the best one: a tank!” The qualitative change in the battlefield produced by a long-range, accurate, tank-killing weapon was completely unexpected.

[Military Intelligence] printed booklets about the Sagger’s characteristics based on information received from the United States, which had encountered the missile in Vietnam in 1971. The armored corps command had even developed tactics for dealing with the missile. But neither the booklets nor the suggested tactics had yet filtered down and few tank men were even aware of the Sagger’s existence.NOTE 3

How to answer the Sagger attack would become a major question for the Israelis (and by extension, for anyone who might have to fight Soviet-style forces). The US also studied this, before and after the war. While defenders worked out some countermeasures, they were imperfect; but a decade later, American tankers were still using “Sagger drills” developed by surviving Israeli tankers after their counterattack of 7 October 73 was savaged by infantry anti-tank teams using Saggers and RPGs.

Reshef’s operations officer, Lt. Pinhas Bar, who had accompanied Bardash’s force, assembled the tank commanders and explained the techniques developed in the past few hours for coping with the Sagger. Such impromptu lessons would be going on all along the front as new units took the field alongside tankers who had survived the day.

The Saggers, the “veterans” explained, were a formidable danger but not an ultimate weapon. They could be seen in flight and were slow enough to dodge. It took at least ten seconds for a missile to complete its flight—at extreme range it could be twice that—during which time the Sagger operator had to keep the target in his sights as he guided the missile by the bright red light on its tail. From the side it was easy for the tankers to see the light. As soon as anyone shouted “Missile,” the tanks were to begin moving back and forth in order not to present a stationary target. Movement would also throw up dust that would cloud the Sagger operator’s view. Simultaneously, the tank should fire in his presumed direction, which itself could be sufficient to throw him off his aim.

It was clear to the tank crews that something revolutionary was happening—as revolutionary, it seemed, as the introduction of the machine gun or the demise of the horse cavalry. Tanks, which had stalked the world’s battlefields for half a century like antedeluvian beasts, were now being felled with ease by ordinary foot soldiers. It would take time, in some cases days, before the implications of this extraordinary development would be grasped by higher command. Meanwhile, the tankers would have to figure out for themselves how to survive. NOTE 4

Most of the countermeasures relied on spotting the backblast of the launch and directing fire in that area. The US noted with alarm that the M60A1 tank needed to close to 1000-1500 meters to get its pH up to 50%, and by that point it was well within the range fan of the Sagger.

Other Sagger countermeasures included laying suppressive fire on likely lurking spots, something the US Army had forgotten since World War II and Korea; exploiting terrain, or as the Army put it, “every fold of ground”; keeping formations loose and non-geometric in order to complicate a Sagger gunner’s second-choice if he lost his first target; keeping moving, or firing from hull defilade; and using infantry for close-in protection of tanks. The US had a few advantages, too: its similar suite of missiles, guns and unguided rocket AT weapons had fewer minimum-range problems and generally superior accuracy and reduced training demands.

Even after the war, the Israelis struggled to find countermeasures. Uzi Eliam remembers:

Egyptian infantry infantry forces with Saturn missiles constituted a serious threat to our tanks. Maj. Gen. Albert Mendler, commander of the Southern division (the 252nd) in the Sinai Peninsula, was hit by a Egyptian antitank missile and died of his injuries…. NOTE 5

[Deputy CGS Israel] Tal was extremely concerned about the threat of the Sagger missiles which he himself had not completely understood before the war. During the years of the War of Attrition along the Canal, our observation posts had observed closed train cars arriving at the front lines. Each time such a train car reached the position of an Egyptian military unit, a long line of soldiers would form near the door, and the soldiers would enter the car one at a time. At first, we made jokes about the train cars, referring to them as mobile sexual service units similar to the kind operated by the Syrian army before the Six-Day War. However, we quickly realized that the train cars contained training simulators for Sagger missile operators.

At R&D, we thought about different ways of addressing the threat with the American developed Mk19 40 mm grenade machine gun. This machine gun was vehicle mounted, and had a firing rate of 350 grenades a minute and a range of 1500 m. … The proposal to add the system to our armored vehicles was decisively rejected by Operations Branch Chief Tal. According to his dogma, what he called “foreign elements” could not be introduced into tank battles.

Although we started searching for a technological solution to the SAG or missile about 10 days after the outbreak of the war the moment the first missiles fell into our hands, we were unable to find a shortcut or a quick solution…. Tal now invoked his authority as Deputy CGS… [with others]… he put all his energy into finding a solution to the problem. The solution he selected involved positioning net fences and coiled barbed wire around tank encampments in order to cause early detonation of fired Sagger missiles before they hit the tanks themselves. NOTE 6.

Despite our best efforts it took more time to develop responses to the Sagger missile. Many ideas were tried… including the possibility of disrupting the missile command system in midflight, misdirecting the missile navigator, and physically obstructing the missile with a steel net in close proximity of the target. The simple Russian missile was not susceptible to our disruption efforts, and we only found a proper solution to the threat posed by the Sagger missile years later. NOTE 7.

But of course, the Russians were not sleeping, and they had better weapons on the drawing board, already. But that’s another story, perhaps for some other day.

Meanwhile their 1973-vintage missiles were a key to the Arab nations’ hopes to recover territory, and pride, lost in the calamitous defeat of 1967. That’s the next, and we think last, installment of this story, the story of early ATGMs.

Notes

- Eilam disagrees with this, noting that US policy was only to provide new technology to Israel once the Israelis had shown themselves capable of producing their own, in order to discourage “escalation” and an “arms race.” These are diplomatic (i.e., State Department) terms; while the US DOD then strongly slanted towards Israel, State was then (as now) a hotbed of antisemitism and anti-Israeli feeling.

- All these charts come from US Army, TRADOC Bulletin 1u, and were originally prepared as briefing view-graphs (powerpoint before there was powerpoint).

- Rabinovich, Kindle Locations 653-655

- Rabinovich, Kindle Locations 2092-2108.

- Eilam, p. 108.

- Eilam, pp. 138-139.

- Eilam, p. 148.

Sources

Kelly, Orr. King of the Killing Zone: The Story of the M1, America’s Super Tank. New York: WW Norton & Co., 1989.

Eliam, Uzi. Eliam’s Arc: How Israel Became a Military Technology Powerhouse. Sussex University Press, 2011.

Rabinovich, Abraham. The Yom Kippur War: The Epic Encounter That Transformed the Middle East. Knopf Doubleday Publishing Group. Kindle Edition.

US Army, Training and Doctrine Command. TRADOC Bulletin 1u: Range and Lethality of US and Soviet Anti-Armor Weapons. Ft. Monroe, VA: TRADOC, 30 September 1975. Retrieved from: http://www.dtic.mil/dtic/tr/fulltext/u2/a392784.pdf

What’s Up in the 3D Printed Gun World?

Time for an update, eh?

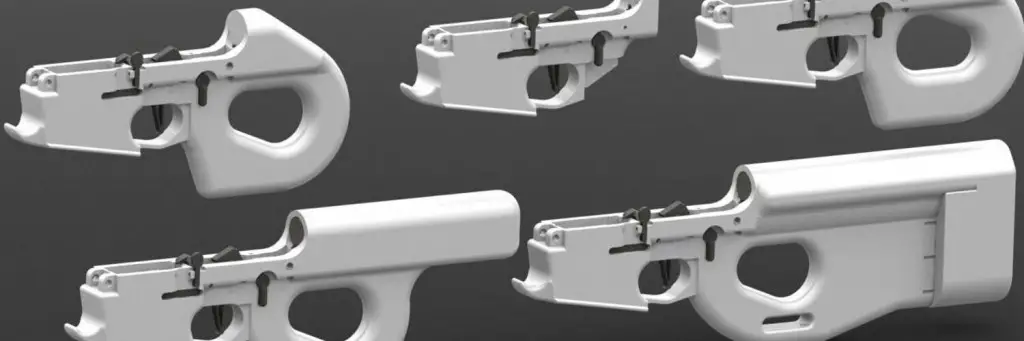

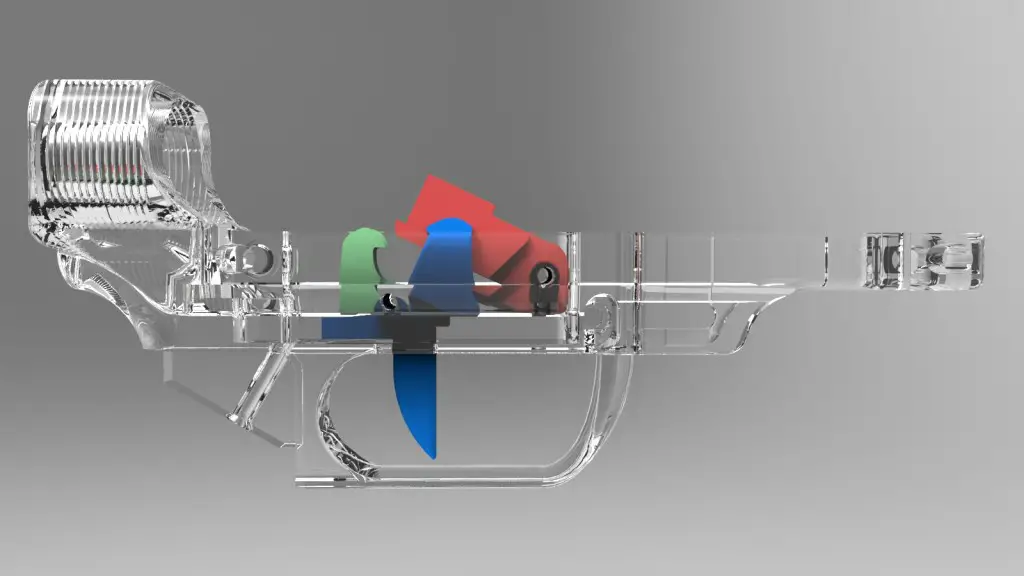

We’ve been seeing really creative AR lowers for a while now. A lot of the greatest ingenuity, like the FN-inspired creations above, come from the innovator who calls himself Shanrilivan and his creative entity WarFairy Arms. Watching his Twitter feed, or @FOSSCAD’s, is a good way to keep up with what’s coming from the community. (Coming soon: AR and AK fire control groups, for example):

If you think there’s no innovation happening in firearms, you’re not tapped into the maker community inside the gun community — or is it, the gun community inside the maker community?

Some Words about Development

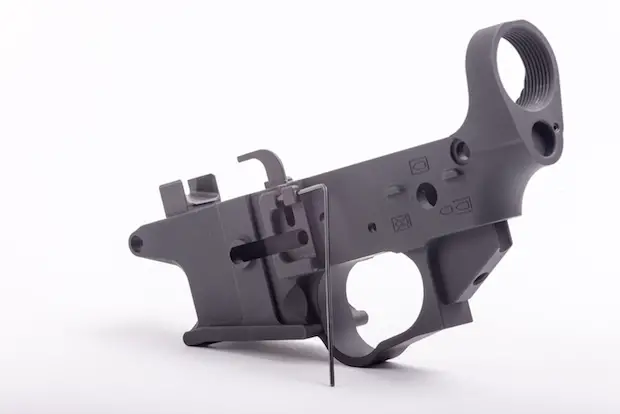

These lowers are not being “engineered” in any real sense of the word. Instead they’re being designed, and are then being tested, in a very tight closed-loop development cycle. From lowers that busted in a couple of shots, we’ve got lowers that have endured thousands of rounds. And that look stylish. This pastel AR has a printed lower and printed magazine.

It’s ready for its close-up, Mr De Mille:

To see about 15 more pictures of printed-gun developments, including magazines, a 7.62mm lower, a revolver, and more, click the “More” button.

Continue reading

AR 9mm Billet Lower

If you’ve ever wanted to build an AR in 9mm (maybe using that DEA upper that’s lying around on a pistol?) you may have been deterred by the difficulty in making a 9mm AR run, or the general fiddliness of the conversion, with a magazine-well adapter roll-pinned in place. Well, the guys at Gun Point have thought of you.

There are some pretty cool features on this lower, which is designed for the Colt AR magazine. Since the full length front to rear of a 5.56 magazine is not required, the mag well shrinks to the size needed to support the SMG mag, with loooong lugs on the front, well reinforced, to hold the pivot pin. Indexing the magazine into a well that fits — what a concept!

The lower comes with the Colt style extractor, ejector, and feed block in place. It’s approved by the ATF as “Cal-multi” which may be helpful for some of you behind enemy lines where ammuntion purchases are keyed to your registered firearms.

Here is a GunPoint custom SBR built on what appears to have been an early version of this receiver, with a VLTOR upper.

The styling is something you might or might not like, very modern, with an “index cut” in the magwell for one’s trigger finger and pictographs for “safe, semi, and ‘talk to a crowd’ settings” on both sides. The trigger guard is an acquired taste; we prefer the opening mitten guard as seen on the M16, but we can’t deny that this eliminates one of the most common points of failure on AR receivers, especially by new or rushing builders.

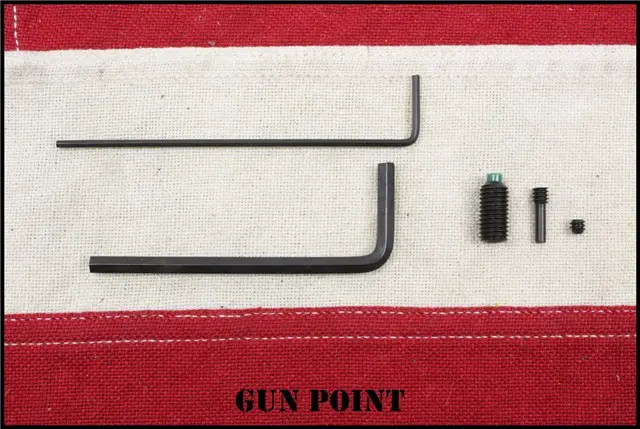

Finally, they’ve banished roll pins by using socket-headed screws for such things as the detents and the bolt catch pivot pin.

The socket-head screws, and the Allen wrenches, come in the package:

Screws-vs-pins is a bit of a double-edged sword. A roll pin is cheap and in normal use will never come out. Screws need loctite, need to be checked periodically, and when they’re gone are a lot harder to replace than a standard-sized roll pin. Both fasteners can come loose, especially if mistakenly installed. (Did you know that roll pins are not designed to be reused? Like the rod bolts in your smallblock Chevy, if you take them off you should put new ones in their places. If someone loses a roll pin from an AR, usually the bolt catch pin, it’s usually because the part was frequently and erroneously removed and replaced. So going the screw route means committing to maintaining the torque and/or loctite on your screws, and going the roll pin route means minimizing post-installation gefingerpoken und slippenouten.

Well, that’s what we say about it. Here’s what Gun Point says about it:

The Gun Point Custom GPM-15 9mm Billet lower receiver is a unique design, sleek and strong built unit that comes with all the features in the top of the line models without the high cost. We have designed this lower with everything you need. NO ROLL PINS!! The roll pin has been replaced with a set screw to eliminate the need of beating on the lower receiver. The rear take down pin detent spring is also held in with a set screw making it easier for you to change buffer tubes. Our receiver tension set screw effectively eliminates any unwanted “slop” between upper and lower receivers for superior accuracy. The oversize trigger guard gives you ample clearance when using gloves and the Finger Rest naturally guides the tip of your finger to the same resting place each time.

This dedicated 9mm lower receiver is designed for the Colt style magazine.

7075 Billet Aluminum

Mil-Spec component compatible

Upper tensioning set screw 1/4 – 28x .375

Bolt Catch screw in pins in place of roll pins

Bolt Catch 6-32 pivot screw included

Threaded saftey detent hole for 6-32 set screw

6-32 x .125 Saftey Detent set screw included

Integrated Oversize Trigger Guard

Finger Location Identifier / Finger Rest

Bullet pictogram selector markings

Type III Class 2 Hardcoat Anodized Finish (Standard)

Optional Cerakote colors available – Add $30

It will set you back $318 shipped to your FFL, but there’s an introductory price of $264, including shipping.

We have not tried this lower, and in fact we generally prefer forged to billet receivers in AR-land… but we have had dealings with Felix at GunPoint / AV Guns, in fact, a customer service problem where a rifle rack we ordered via Gun Broker was destroyed by the carrier enroute. Despite the fact that he’s one of the busiest NFA dealers in Florida, Felix and his guys got personally involved and made their customer — your humble WeaponsMan — whole, waiting themselves for the reimbursement from the freight company.

Like many great Americans, Felix knows what it’s like to taste American freedom after suffering under foreign tyranny. If you thought you were a patriot, check out guys like him sometime.

We can, therefore, recommend these guys and this company without reservation, which adds up to a thumbs-up for their new lower, sight unseen.

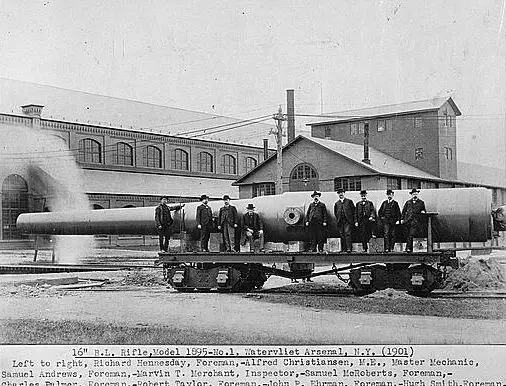

State of The Art(illery): 1884

Watervliet Arsenal, where this cannon was once displayed, comes up in this story. But this cannon wasn’t made at Watervliet. It was captured from Johnny Burgoyne!

In the last quarter of the 19th century, it sank in to the American military that important advances in gun manufacture had been taking place in Europe, while the US is heavy gun development and stagnated since the Civil War. The War Between the States was the last war in which the United States had needed a lot of artillery, and not surprisingly, it had been the last time the Army and Navy had spent significant money on artillery technological development. Since 1865, most fighting had taken place against Indian tribes, and these light, mobile counterinsurgency battles didn’t implicate heavy weaponry. After all, Custer had famously left his cannon — and Gatlings — behind, making a judgment that gave priority to the mobility of his cavalry force. That it is now one of the more thoroughly second-guessed judgments of all military history is small consolation to Yellow Hair: as he would no doubt say if we could interview him, “It seemed like a good idea at the time!”

Of course, the heavy weapons that Custer had in 1873, and that his successors would have had a decade later, were little improved from those of the Civil War. The Artillery Branch’s focus had been on development of heavy artillery for siege and especially for coastal use, and if one attended the Artillery School at Fort Monroe, VA in this period, he’d learn, along with a heavy dose of theory, the following guns: 3-inch, 8-inch, and 21-pounder, along with the 4.5 inch siege gun and a couple of Seacoast Mortars.1

Meanwhile, the Germans and Austrians (actually, the Austrians’ Czech gunmakers) had invented the recoiling gun carriage and the armies of Europe were rearming with a new generation of highly accurate breechloaders, made of steel and not iron.

So our Army and Navy thought it best to take a systematic look at their needs for artillery, how the Europeans had met similar needs, and how the US might equal them. This required an act of Congress in 1883, and a report to the President (do you know who was President? Neither did we. Chester A. Arthur) in the next year. One copy of that report, which was approved by Arthur in February, 1884, was filed in the library of the Infantry and Cavalry School in October of that year, and is now available in .pdf from the school’s successor, the Combined Arms Reference Library.

Results: a little over 10 years later, these buildings, and guns like this, emerged from the report’s recommendations.

The board comprised six officers who traveled to government arsenals and private factories in England, France and Russia. They also corresponded at length with Friedrich Krupp, who in the end declined to host them at his plant in Essen. The original book contains the Krupp correspondence in its appendices, all of which unfortunately are missing from the truncated .pdf version available in Sources below.

The report noted the parlous state of US Artillery at the time. After listing the arsenals and contractors that produced the Union’s artillery in the Civil War, then nearly 20 years in the past, it noted how scant American postwar developments had been:

Since the termination of the war the Fort Pitt Foundry has ceased to exist. The South Boston Iron Works Company has manufactured a few experimental guns, and with the West Point Foundry has executed some small orders of the Government in the conversion of cast-iron smooth-bores into rifle guns by inserting and rifling a coiled wrought iron tube.

None of the companies mentioned above have ever made steel guns, and virtually the United States is destitute of a source from which such, an armament as the age demands can be supplied.

Before the introduction of rifled cannon and the use of steel as the material for their construction, the United States boasted of her Dahlgren and Rodman cast-iron guns, which were the models for imitation and the standards for comparison of all nations.

While the rest of the world has advanced with the progress of the age, the artillery of the United States has made no step forwards. Its present condition of inferiority is only the natural result of such want of action.2

The report describes with remarkable concision the economics, location, and process of manufacturing artillery in the nations that cooperated, and goes on to describe the guns themselves and their technology in great detail.

Whitworth’s Works

Other English firms reported that Sir Joseph Whitworth, the eminent inventor and engineer, was quite as secretive a Krupp himself, but Whitworth invited the officers to visit his factory — under the condition that they only do so after seeing all the others. That seemed like a small enough concession, and so they did just that, only to find that Whitworth really was doing something remarkable.

The other factories were well ahead of the Americans’ home industries: they were casting breech-loading gun tubes, and making hoops for them, of steel. But what Whitworth was doing blew the Americans’ minds:

In speaking of the Whitworth establishment at Manchester as unique, and of the process of manufacture at that place as a revelation, reference is specially made to the operation of forging. As to the assorting of ores, and the treatment of metal in the furnaces, there is no intention to draw distinctions; but as to the treatment of the metal after casting there can be no doubt of the superiority of the system adopted by Sir Joseph Whitworth over that of all other manufacturers in the world. The process here adopted has been kept singularly exempt from scrutiny. Even in the offices of the chiefs of artillery there can be found no information, within the knowledge of the Board, which is at all satisfactory upon the subject. Whatever knowledge there is seems to come from hearsay—-none from personal observation—and it is only from personal observation that the merits of the system can be fully appreciated.

The system of forging consists in compressing the liquid metal in the mould immediately after casting, and in substituting a hydraulic press for the hammer, in the subsequent forging of the metal.3

The exact details of the process follow, and then the conclusion:

The Board witnessed the operations of casting followed by that of liquid compression, the enlarging of hoops, the drawing out of cylinders, and the forging of a solid ingot. The unanimous opinion of the members is that the system of Sir Joseph Whitworth surpasses all other methods of forging, and that it gives better promise than any other of securing that uniformity so indispensable in good gun metal.

The latest exhibition of the wonderful character of the Whitworth steel has attracted great attention, and may be stated as indicating the present culmination of his success. From a Whitworth 9-inch gun, lately constructed for the Brazilian Government, there was fired a steel shell, which, after perforating an armor-plate of 18 inches of wrought iron, still retained considerable energy. The weight of the shell was 403 pounds, the charge of powder 197 pounds, and the velocity about 2,000 feet. The shell is but slightly distorted. The tests of the metal of which it was made show a tensile strength of 98 tons per square inch and a ductility of 9 per cent.4

They were very favorably impressed by the Russian factories, which seemed to borrow eclectically from Whitworth and Krupp alike, and relied on excellent Russian ores. They noted an accident that demonstrated the strength of Russian artillery design:

A recent accident gave a severe test to the system of construction adopted for Russian artillery. In experimenting with gun-cotton for use in shells, one of the latter, containing 40 pounds, exploded in the chamber of an 11-inch gun when the charge of gunpowder (128 pounds) was fired. The rear part of the breech was blown off at the weak point of the Krupp system. The trunnion-band was broken, throwing off a fragment; and the diameter of the chamber was enlarged 1 inch. The admirable quality of the metal, and the good adjustment of the strength of the several parts is evident from this statement.5

That would have been unpleasant for the gun crew, we suspect.

The Russian guns were also unique in being designed with a thin liner that allowed artillery to be rapidly and economically overhauled.

The operation of inserting one of these lining tubes in a field gun was witnessed at Aboukhoff. The difference of their diameters was very small. The fitting of the slightly conical surfaces by measurement before insertion was done with precision.

When ready for insertion the lining tube was lubricated and intro duced by hand. It was forced by hand levers until the end was nearly flush with the breech; hydraulic power then applied by a hand-pump was gradually increased to a pressure of 180 atmospheres, although no motion was apparent after it had reached 100 atmospheres. The rear end of the lining tube forms the recess for the Broadwell ring.

The Russian officers claim that these tubes can be renewed in the field, and cited instances of two 9-inch mortars, weighing 5½ tons each, needed for use on the Danube during the late war. Being too heavy for the available means of transportation they were forwarded in three pieces— a tube, a breech-jacket and a muzzle-jacket. The two latter were screwed together, and the tube was inserted by a jack on the spot; both mortars did excellent service.6.

Consequences of the Report

The Report made several recommendations:

- That the Government build its own artillery, rather than purchase it or enter into a public-private partnership, or, as they put it, “The Government should establish on its own territory a plant for the fabrication of cannon, and should contract with private parties to such amounts as would enable them to supply from the private industries of the country the forged and tempered material.” The officers thought that the provision of private profit increased Government costs. (They might have been artillerists, but they weren’t economists).

- That the Army and Navy have separate facilities. “This has al ways been the custom in France, producing good results; the reverse has been the practice in England, producing bad results.”

- That the Army construct its factory for artillery tubes at Watervliet, New York, where plentiful hydraulic power would enable manufacturing.7

- That the Navy build theirs in the Washington Navy Yard.

- And of course, the officers asked for money:

The facts that the United States is destitute of the means of fabricating the modern guns so urgently needed for national defense, and that at least three years will be required to complete the tools, construct the shops and establish the plant, would seem to demand an immediate appropriation of the amount ($1,800,000) estimated for the establishment of the proposed gun factories.8

So it was written; and, quite remarkably, so it was, more or less, done. The US still makes its artillery tubes at Watervliet Arsenal!

Notes

- Daugherty, p. 13.

- Foundry Board Report, p. 39.

- Foundry Board Report, pp. 14-15.

- Foundry Board Report, p. 16.

- Foundry Board Report, pp. 37-38.

- Foundry Board Report, p. 38.

- Watervliet once had a decent museum on base, but it closed in 2013 in a Provost Marshal’s blind security panic, and will never reopen; the exhibits are to be shipped to distant Army museums, stored and forgotten, or, in the case of heavy and bulky exhibits the Army Center for Military History doesn’t want to pay to ship or store, scrapped.

- Foundry Board Report, pp. 50-51.

Sources

Daugherty, Leo J. III. Pioneers of Amphibious Warfare, 1898-1945: Profiles of Fourteen American Military Strategists. Jefferson, NC: McFarland, 2009.

Simpson, et. al. Report of the Gun Foundry Board: Organized by The President in Accordance With the Act of Congress, Approved March 3, 1883. Washington: Government Printing Office, 1884. Available at http://cgsc.contentdm.oclc.org/cdm/compoundobject/collection/p4013coll11/id/722 or here at WeaponsMan: Report of the Gun Foundry Board 1884.pdf (10.5 mb PDF).

ATGMs Go to War, Vietnam, 1972

In 1972, ATGMs had been in military inventories for 20 years, since France’s adoption of the SS-10 circa 1951. But they’d never fulfilled their original mission — destruction of enemy tanks in combat. Sure, some of the French missiles might have been popped off an insurgent sangars in Algeria, and Americans shot a couple of Entacs at bunkers in Vietnam. And a dozen missile models had blown hell out of obsolete tanks on a firing range. But nobody had shot one at a hostile tank containing a hostile crew.

1972 was the year that the wire-guided anti-tank missile got its cherry popped, in Vietnam conflict. Before the next year was out the missiles would prove almost decisive in tank-on-tank combat — and be employed on both sides. If the weapons world of New Year’s Eve, 1971, had its issues with anti-tank guided missiles — and the US had such gadflies as the Project on Military Procurement (whose funding and control was shadowy) and the Soviet-line Center for Defense Information trying to force cancellation of ATGM programs — the weapons world of New Year’s Day, 1974, had shaken off all doubts. Missiles were here to stay.

Those wars were the 1972 NVA conventional invasion of South Vietnam and the Yom Kippur War, both of which saw missiles used, in the first experimentally, and in the second in great quantities. Here is an overview video of TOW missile attacks on North Vietnamese armor.

Click “more” for the details about Vietnam. The Yom Kippur War story will be told in the days ahead.

Continue reading

Anti-Tank Missiles — America’s Early Years

We’ve discussed the original German developments on wire-guided missiles, and the way the US Army didn’t pick uo on them until it was imagining its ultimate tank-killer in the late 1950s. That missile program was rolled into one of Robert S. Macnamara’s grandiose schemes, the international MBT-70 tank, that was going to be the best tank in the world by such a margin that all NATO would adopt it. (Instead, it wound up being a bitter, painful and costly learning experience for the US and Germany).

A Note About Interational and Combination Programs

International programs always have great appeal to deskbound defense intellectuals like Macnamara. It’s an instantation of a set they can’t resist, making one general thing replace two or more specialized ones. Therefore it’s always easy to sell DOD suits on something like the M14 replacing the M1 rifle, M1 carbine, M3A1 SMG, M1918A2 automatic rifle, and M1919A6 squad machine gun, all in one fell swoop. The problem is, of course, that the M14 was okay to replace the rifle and maybe the carbine, but couldn’t quite do what the grease gun and the BAR did, and was not even in the same game, capability-wise, as the light machine gun. This is not a criticism of the M14, it’s a criticism of the boneheaded idea that a general-purpose rifle can replace something developed for another general-purpose entirely. From the beginning the M14 was intended to replace the M3A1 as well as the M1 rifle, but it wound up being longer and bulkier than the M1, something many people don’t understand because of the M14’s clean, attractive, carbine-like lines.

While the graveyards of defense procurement are rich in “not just a toaster, but also a blender!” false starts, the problems of neither-fish-nor-fowl procurement are compounded by international programs. Now you have to deal with different requirements that are rooted in different doctrines and even concepts of war. The MBT-70 was the compromise hellchild of incompatible American and German concepts of what a tank was for. The Americans envisioned a tank so good it could fight and win despite being grossly outnumbered, and that fired missiles. The Germans, having tramped that road to its logical conclusion in WWII, wanted a tank they could afford to build in such quantity that they wouldn’t have to fight grossly outnumbered, and they saw the tank-gun-missile-launcher as the boondoggle it was. NATO politics forced both nations, whose armies had a tradition of mobile, offensive-oriented tank fighting, onto a war plan comprising static defense in place. So the best tank minds of two of the world’s top five tank-fighting nations poured themselves for years into a project whose demise was written in its congenital deformation.

As a rule of thumb, odds of failure of a given military procurement project increase by the exponent of the number of armed services involved.

Meanwhile, Back in La Belle France…

While the Americans and Germans tied themselves into knots trying to make a Ronco does-everything tank (and the Americans, to build a missile it could launch), something interesting happened in France. French engineers picked up where Dr Kramer left off with his wire-guided AT missile. Within a few years, they had a design for one that would work, and they showed it off to their allies, hoping for some help. So, about 1951, French officials showed American officers the experimental SS-10 missile. It was a small, barely man-portable or jeep-launched missile that could deliver a whopping hollow charge onto a tank with precision, given a well-trained operator.

SS-10 in US service in 1961. With its ends popped off and propped up with a built-in monopod, the box became a launcher.

The SS-10 incorporated Manual Command to Line of Sight or MCLOS guidance. A sodium flare in the missile’s tail let the missileer steer the weapon, which he flew onto target with a joystick. (This was generally how Kramer’s system had worked). The weapon came to American attention in 1951, according to a once-classified US history:

The French SS-10 missile evolved from the German RuhrstahZ, or X-4, a single-wing, wire-guided, roll-stabilized missile originally developed as an air-to-air missile late in World War 11. The Germans were ready to begin mass production of the Y-4 early in 1945, but their plans were interrupted by costly delays in acquir- ing suitable solid-fuel rocket engines and by the relentless bombing of research and manufacturing centers by Allied planes. Recognizing the potentialities of the X-4 as a surface-to-surface antitank weapon, the French continued-its development after the war ended.lO The resultant product was the SS-10, a ground- launched, cruciform-wing missile about 34 inches long with a 30-inch wing span. It had a gross weight of 34 pounds and carried an 8.9-pound shaped-charged warhead for an operational range of about 1,500 yards. Like the X-4, the SS-10 was an optically-guided, wire-controlled missile — features later incorporated i n the DART guided missile system.

The Ordnance Corps became interested in the SS-10 a s a potential antitank weapon late in 1951 and subsequently supported the development program with primary emphasis on procurement, test, and evaluation of the system. Early in 1952, 500 SS-10 missiles and 3 sets of ground equipment were procured from the French Government for use in evaluation tests by the Ordnance Corps at Aberdeen Proving Ground, the AFF Board No. 3 at Fort Benning, Georgia, and the U. S. Marine Corps at Quantico, Virginia. The evaluation program began in December 1952 and continued until October 1953, when it was discontinued because of unfavorable test results. Members of the AFF Board No. 3 recommended that the SS-10 missile, in its current state of development, be considered unsuitable for use by the U. S. Army, and that future French development of the missile be carefully observed with a view to reconsideration of the weapon if an improved model should be produced before a comparable American weapon became available.

Click “more” to continue with the Comparable American Weapon — a dead-end — and America’s return to French missiles for the 1960s, and developments to the early 70s.

Continue reading

Loose Rounds on the M14

We have a soft spot in our heart for the M14 rifle, even though we experienced it in the service primarily as the M21 sniper system, a fiddly, unstable platform with, “no user serviceable parts inside.” (Seriously. The operator was not permitted to field-strip the gun — that was strictly for the armorers who built the thing. You could swab out the bore, but they’d rather you didn’t). Some of the fiddliness was caused by the Leatherwood ART II scope, an early bullet drop compensator telescopic sight. The Leatherwood was adopted, we always suspected, because Jim Leatherwood had been an SF guy, not because the scope was incredibly great. The replacement of the M21 with the M24 bolt gun, a gun that was developed primarily by SF marksmen (snipers and competitive shooters), was met by hosannas. Its Leupold mildot scope took the onus off the scope’s internals and put it on the shooter, and we liked that.

So when Shawn at Loose Rounds penned a post critical not as much of the M14 but of its somewhat unsupported legend of battlefield prowess, he was aiming right up our alley. He has technical support in that post from Daniel Watters, arguably the most knowledgable man on post-WWII US small arms developments not to have written a book. And his arguments are generally supported by the M14-related books in our collection, some of which appear in footnotes or Sources.

The M14’s history is interesting. It had a long and arduous gestation, involving many false starts and dead ends, before finally settling on a weapon that was a little more than an M1 with a box magazine and improved gas system. This whole process took 12 years (from 1945 to 1957) and cost a surprising fortune, considering that what came out of it was essentially an M1 with a box mag, useless selective-fire switch, and improved gas system.

From the operator end, it looks just like an M1, except for that dopey and wasteful giggle switch, but you can actually reload an M1 faster.

The M14’s prototype, the T44, came this close (Max Smart finger gesture) to losing out to the US-made FN-FAL version, the T48. The final test found the two weapons roughly equivalent.1 Previous tests greatly improved both arms, and made one lasting improvement in the FAL hat benefited FN and foreign operators: the incorporation of the “sand cuts” in the bolt carrier.2 One deciding factor was that the FN rifle did not have “positive bolt closure,” a way to force the bolt closed on, say, a swollen cartridge. (Never mind that that’s a crummy idea, it was Army policy. Some say, in order to accept the home-grown, Springfield-developed T44 instead of the foreign-designed FAL, but that’s certainly not written down anywhere important).

The M14 went on to have a surprisingly difficult time in manufacturing — surprising because it had been sold on extensive commonality with M1 Garand design, and sold as producible on M1

Garand tooling. All manufacturers (Springfield, Winchester, Harrington & Richardson, and TRW) struggled to make the guns. (Stevens calls M14 production, in a chapter heading, “A Tragedy in Four Acts.”3 In H&R’s case it was not surprising, as H&R had struggled with an M1 contract and only had an M14 contract because of political corruption in the Massachusetts congressional delegation, TRW, which is generally thought to have produced the best rifles of the four manufacturers.4

The M14 was supposed to replace the M1, but also the BAR, carbine, and SMG. Until you see them side by side, most people assume the M14 was smaller than the M1. This “M14″ is actually a civilian Springfield M1A. (image: Rifle Shooter mag)..

In fact, only a few M1 parts are interchangeable with the M14, including most internal parts of the trigger housing group, and some of the stock hardware, A few other parts, like the extractor and rear sight aperture, interchange but aren’t quite “right.” (The M14 extractor works better in either rifle; the M1 and M14 sights are calibrated in yards and meters respectively).5

The M14 had a short life as a US service rifle, and a controversial one. (Congress, for one, couldn’t believe the amount of money that had been spent for a relatively marginal improvement over the M1). But it has had a long afterlife as stuff of legend. And this where Loose Rounds’ most recent effort in mythbusting comes in. Here is a taste:

Go on to any gun forum, and it won’t take you long to find people willing to tell you how great the M14 is. How accurate,like a laser, tough as tool steel with no need to baby it or clean it. powerful as a bolt of lightening, and how well loved it was by those early users who refused the M16 because they wanted a “real” weapon made of wood and steel…. .. But, is all that really true? Maybe it is a triumph of nostalgia over common sense and reality. One truth is, it was never really liked as much as people think they remember.

The M14 was having major problems even before ARPA’s Project AGILE and a Defense comptroller reported the AR15 superior to the M14;the famous Hitch Report stating the AR15 , the M1 and the AK47 superior.

(Loose Rounds then quotes those exact conclusions from those reports, which are also referenced in many of the Sources we list at the end of this document).

My own Father had this to say. Dad was in Vietnam from 67-68 in the 4th Infantry Division.

“I liked the M14 in basic, It was the first semi auto I had ever fired. It got old carrying all that weight fast running every where all day and night. I qualified expert with it. Once I was issued an M16 right before we over seas, I never looked back.”

For every person who has told me how great the thing is, I have found two who had nothing by misery and bad experiences from it. I myself among them.

…

The M14/M1a will be around for as long as people will continue to buy them. Certainly there is nothing wrong with owning them liking them and using them. By no means is it useless or ineffective. But its legendary reputation is something that needs to be taken with a grain of salt and careful study of the system if you intend to have one for a use your like may depend on.

If you are curious posts on shooting rack M14s and custom service rifle M14s with Lilja barrels fired at 1,000 yards can be found here on Looseorunds using the search bar. There you can read of the M14/M1A compared against the M1 Garand and M1903.

When we sat down last night to start writing this, we were going to analyze their post in great depth, but we can only suggest you go Read The Whole Thing™. The M14 is very beloved, but then, many soldiers come to love their first military rifle quite out of proportion to its qualities. (Indeed, we feel that way about, and retain a limerent attachment to, the M16A1, while recognizing that progress has left the original Army M16 behind).

If nostalgia drives you, LRB has this rifle on a new T44E4 marked receiver in stock — for nearly $3k. We want it but not $3k bad!

Indeed, there is a space on the gun room wall marked out for an M21, sooner or later. But that;s where it is likely to stay most of the time. (Shawn’s post at Loose Rounds has some details about the fiendish difficulty of keeping one of these in accurate shooting trim).

Notes:

- Stevens, North American FALs, p.106; Iannimico, p. 62.

- Iannimico, p. 59.

- Stevens, US Rifle M14, pp. 197-224l

- Emerson, Volume 1, pp. 41-70

- Emerson, Volume 3, pp. 129-130.

Sources

Emersom, Lee. M1 History and Development, Fifth Edition. (Four Volumes). Self-published, 2010-2014.

Iannimico, Frank. The Last Steel Warrior: US Rifle M14. Henderson, NV: Moose Lake, 2005.

Rayle, Roy E. Random Shots: Episodes in the Life of a Weapon Developer. Bennington, VT: Merriam Press, 1996.

Stevens, R. Blake, North American FALs. Toronto: Collector Grade Publications, 1979.

Stevens, R. Blake, US Rifle M14: From John Garand to the M21. Toronto: Collector Grade Publications, 1979.

Ghost Gunner Update — Received 26 January

Everyone who ordered one of these should have gotten this update. It’s shared here for those of you who are just curious, not committed. Consider it a Guest Post by Cody R. Wilson. -Ed.

Hey Ghost Gunners. Time for a production update.

We spent the first week of January correcting our enclosure provider’s specification errors, to eventual success. We then proceeded to junk 1200 pounds of powder-coated steel. And yes, they ate the cost.

|

|

We had been working with a supplier for CNC and lathed parts who was supposed to ship us production parts sets by mid-December, but he missed his goal and promised delivery in early January. Those parts did arrive this month, but of the critical sets only about 20% currently meet our specifications.

We began to suspect this supplier’s abilities at the end of the year, however, and were able to bring on a more reliable and professional supplier in Austin to replace this work and make up for time lost on enclosures.

|

|

These [Does he mean “Three”? -Ed.] months for this work product.

So, as it stands today, we think we’re only going to be shipping about 18-20 machines this month. Our new supplier should get our part stream way up in February, and most people should see their GG in the mail in as soon as three weeks. To you backers who were expecting Holiday delivery, I can only thank you for your patience and promise you a valuable product.

To you on the wait list, I will be able to call up 40 to 50 of you once we ship the first 100 machines through February. You’ll receive an email from DD.

There is still a lot to discuss from this month, however.

250 calibrated spindle motors.

Yes, we’ve been hard at work making the guts of nearly 300 machines so far. We’ve been afforded extra time in the delays for software adjustments and V&V on our custom electronics (more about those when the occasion is happier).

We’ve staffed up enough to have people in the shop around the clock, but this is still not what we need to talk about.

|

|

|

|

|

|

We should talk about ATF 2015-1.

The first week of this new year, Obama’s Justice Department, through his ATF, gutted the traditional trade in 80% lower completion. It doesn’t matter what their story is, the move was made to destroy 50 years of industry precedent and squeeze you out of access to commercial grade CNC equipment to privately, and I should add constitutionally, equip yourself with your own AR.

Now, this new ATF regulation does not affect your purchase of this machine and our ability to sell it to you. Indeed, the Obama Administration has just made this Ghost Gunner endeavor in which we’ve all joined extremely important. As of January, the only way you can use CNC to finish your lower is to buy a machine. Your absolute government knows most law-abiding people cannot afford their own CNC, and so they have forced you to rely on hand tools if you want a private AR-15.

But now the world has a Ghost Gunner.

This month, Come and Take It Texas demonstrated one of our first production machines at the Texas State Capitol to welcome the new legislators.

|

The responses from the open carry groups were meek and anxious.

So let’s be very clear.

This project and our company are about expanding your franchise as freemen. And in the face of overwhelming opposition. Your governors, legislators, lobbyists and industry friends do not give a damn about your right to have this rifle outside of commerce and surveillance.

The Feds are doing everything they can to stop this project. Just this week we received a contemptuous letter from DoD denying cognizance of our technical data requests, and late last year we were threatened directly by the DTSA.

I say all this to say that we are serious. The enemy will do anything to stop this and they are doing it, and we are trying with all of our might to ship these machines and their software to you. It is the only thing any of us are doing, and though the pressure feels enormous I am thankful to have the opportunity to deliver this tool to you.

***

There is a volume of information I want to share about DD’s ongoing battle with the Obama regime. And I promise disclosure of this information after we begin shipping GG’s in quantity. You should know specifically what your government thinks of you and your First and Second Amendment.

Machines incoming!

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.