Category Archives: Weapons Technology

Time for an update, eh?

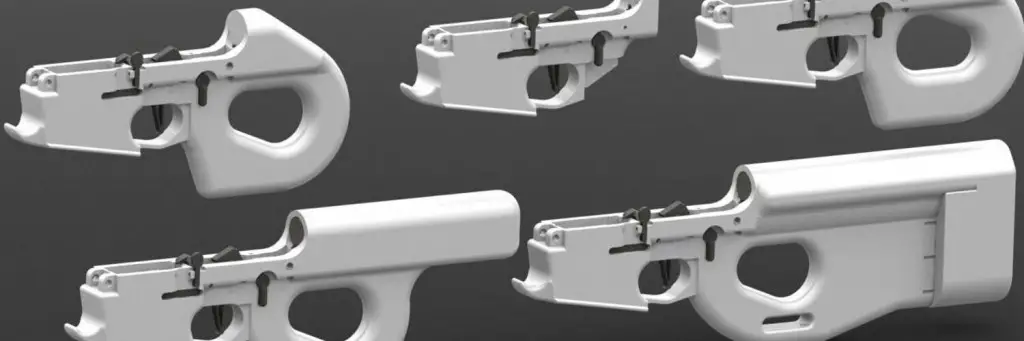

We’ve been seeing really creative AR lowers for a while now. A lot of the greatest ingenuity, like the FN-inspired creations above, come from the innovator who calls himself Shanrilivan and his creative entity WarFairy Arms. Watching his Twitter feed, or @FOSSCAD’s, is a good way to keep up with what’s coming from the community. (Coming soon: AR and AK fire control groups, for example):

If you think there’s no innovation happening in firearms, you’re not tapped into the maker community inside the gun community — or is it, the gun community inside the maker community?

Some Words about Development

These lowers are not being “engineered” in any real sense of the word. Instead they’re being designed, and are then being tested, in a very tight closed-loop development cycle. From lowers that busted in a couple of shots, we’ve got lowers that have endured thousands of rounds. And that look stylish. This pastel AR has a printed lower and printed magazine.

It’s ready for its close-up, Mr De Mille:

To see about 15 more pictures of printed-gun developments, including magazines, a 7.62mm lower, a revolver, and more, click the “More” button.

Continue reading

Anti-Tank Missiles — America’s Early Years

We’ve discussed the original German developments on wire-guided missiles, and the way the US Army didn’t pick uo on them until it was imagining its ultimate tank-killer in the late 1950s. That missile program was rolled into one of Robert S. Macnamara’s grandiose schemes, the international MBT-70 tank, that was going to be the best tank in the world by such a margin that all NATO would adopt it. (Instead, it wound up being a bitter, painful and costly learning experience for the US and Germany).

A Note About Interational and Combination Programs

International programs always have great appeal to deskbound defense intellectuals like Macnamara. It’s an instantation of a set they can’t resist, making one general thing replace two or more specialized ones. Therefore it’s always easy to sell DOD suits on something like the M14 replacing the M1 rifle, M1 carbine, M3A1 SMG, M1918A2 automatic rifle, and M1919A6 squad machine gun, all in one fell swoop. The problem is, of course, that the M14 was okay to replace the rifle and maybe the carbine, but couldn’t quite do what the grease gun and the BAR did, and was not even in the same game, capability-wise, as the light machine gun. This is not a criticism of the M14, it’s a criticism of the boneheaded idea that a general-purpose rifle can replace something developed for another general-purpose entirely. From the beginning the M14 was intended to replace the M3A1 as well as the M1 rifle, but it wound up being longer and bulkier than the M1, something many people don’t understand because of the M14’s clean, attractive, carbine-like lines.

While the graveyards of defense procurement are rich in “not just a toaster, but also a blender!” false starts, the problems of neither-fish-nor-fowl procurement are compounded by international programs. Now you have to deal with different requirements that are rooted in different doctrines and even concepts of war. The MBT-70 was the compromise hellchild of incompatible American and German concepts of what a tank was for. The Americans envisioned a tank so good it could fight and win despite being grossly outnumbered, and that fired missiles. The Germans, having tramped that road to its logical conclusion in WWII, wanted a tank they could afford to build in such quantity that they wouldn’t have to fight grossly outnumbered, and they saw the tank-gun-missile-launcher as the boondoggle it was. NATO politics forced both nations, whose armies had a tradition of mobile, offensive-oriented tank fighting, onto a war plan comprising static defense in place. So the best tank minds of two of the world’s top five tank-fighting nations poured themselves for years into a project whose demise was written in its congenital deformation.

As a rule of thumb, odds of failure of a given military procurement project increase by the exponent of the number of armed services involved.

Meanwhile, Back in La Belle France…

While the Americans and Germans tied themselves into knots trying to make a Ronco does-everything tank (and the Americans, to build a missile it could launch), something interesting happened in France. French engineers picked up where Dr Kramer left off with his wire-guided AT missile. Within a few years, they had a design for one that would work, and they showed it off to their allies, hoping for some help. So, about 1951, French officials showed American officers the experimental SS-10 missile. It was a small, barely man-portable or jeep-launched missile that could deliver a whopping hollow charge onto a tank with precision, given a well-trained operator.

SS-10 in US service in 1961. With its ends popped off and propped up with a built-in monopod, the box became a launcher.

The SS-10 incorporated Manual Command to Line of Sight or MCLOS guidance. A sodium flare in the missile’s tail let the missileer steer the weapon, which he flew onto target with a joystick. (This was generally how Kramer’s system had worked). The weapon came to American attention in 1951, according to a once-classified US history:

The French SS-10 missile evolved from the German RuhrstahZ, or X-4, a single-wing, wire-guided, roll-stabilized missile originally developed as an air-to-air missile late in World War 11. The Germans were ready to begin mass production of the Y-4 early in 1945, but their plans were interrupted by costly delays in acquir- ing suitable solid-fuel rocket engines and by the relentless bombing of research and manufacturing centers by Allied planes. Recognizing the potentialities of the X-4 as a surface-to-surface antitank weapon, the French continued-its development after the war ended.lO The resultant product was the SS-10, a ground- launched, cruciform-wing missile about 34 inches long with a 30-inch wing span. It had a gross weight of 34 pounds and carried an 8.9-pound shaped-charged warhead for an operational range of about 1,500 yards. Like the X-4, the SS-10 was an optically-guided, wire-controlled missile — features later incorporated i n the DART guided missile system.

The Ordnance Corps became interested in the SS-10 a s a potential antitank weapon late in 1951 and subsequently supported the development program with primary emphasis on procurement, test, and evaluation of the system. Early in 1952, 500 SS-10 missiles and 3 sets of ground equipment were procured from the French Government for use in evaluation tests by the Ordnance Corps at Aberdeen Proving Ground, the AFF Board No. 3 at Fort Benning, Georgia, and the U. S. Marine Corps at Quantico, Virginia. The evaluation program began in December 1952 and continued until October 1953, when it was discontinued because of unfavorable test results. Members of the AFF Board No. 3 recommended that the SS-10 missile, in its current state of development, be considered unsuitable for use by the U. S. Army, and that future French development of the missile be carefully observed with a view to reconsideration of the weapon if an improved model should be produced before a comparable American weapon became available.

Click “more” to continue with the Comparable American Weapon — a dead-end — and America’s return to French missiles for the 1960s, and developments to the early 70s.

Continue reading

Loose Rounds on the M14

We have a soft spot in our heart for the M14 rifle, even though we experienced it in the service primarily as the M21 sniper system, a fiddly, unstable platform with, “no user serviceable parts inside.” (Seriously. The operator was not permitted to field-strip the gun — that was strictly for the armorers who built the thing. You could swab out the bore, but they’d rather you didn’t). Some of the fiddliness was caused by the Leatherwood ART II scope, an early bullet drop compensator telescopic sight. The Leatherwood was adopted, we always suspected, because Jim Leatherwood had been an SF guy, not because the scope was incredibly great. The replacement of the M21 with the M24 bolt gun, a gun that was developed primarily by SF marksmen (snipers and competitive shooters), was met by hosannas. Its Leupold mildot scope took the onus off the scope’s internals and put it on the shooter, and we liked that.

So when Shawn at Loose Rounds penned a post critical not as much of the M14 but of its somewhat unsupported legend of battlefield prowess, he was aiming right up our alley. He has technical support in that post from Daniel Watters, arguably the most knowledgable man on post-WWII US small arms developments not to have written a book. And his arguments are generally supported by the M14-related books in our collection, some of which appear in footnotes or Sources.

The M14’s history is interesting. It had a long and arduous gestation, involving many false starts and dead ends, before finally settling on a weapon that was a little more than an M1 with a box magazine and improved gas system. This whole process took 12 years (from 1945 to 1957) and cost a surprising fortune, considering that what came out of it was essentially an M1 with a box mag, useless selective-fire switch, and improved gas system.

From the operator end, it looks just like an M1, except for that dopey and wasteful giggle switch, but you can actually reload an M1 faster.

The M14’s prototype, the T44, came this close (Max Smart finger gesture) to losing out to the US-made FN-FAL version, the T48. The final test found the two weapons roughly equivalent.1 Previous tests greatly improved both arms, and made one lasting improvement in the FAL hat benefited FN and foreign operators: the incorporation of the “sand cuts” in the bolt carrier.2 One deciding factor was that the FN rifle did not have “positive bolt closure,” a way to force the bolt closed on, say, a swollen cartridge. (Never mind that that’s a crummy idea, it was Army policy. Some say, in order to accept the home-grown, Springfield-developed T44 instead of the foreign-designed FAL, but that’s certainly not written down anywhere important).

The M14 went on to have a surprisingly difficult time in manufacturing — surprising because it had been sold on extensive commonality with M1 Garand design, and sold as producible on M1

Garand tooling. All manufacturers (Springfield, Winchester, Harrington & Richardson, and TRW) struggled to make the guns. (Stevens calls M14 production, in a chapter heading, “A Tragedy in Four Acts.”3 In H&R’s case it was not surprising, as H&R had struggled with an M1 contract and only had an M14 contract because of political corruption in the Massachusetts congressional delegation, TRW, which is generally thought to have produced the best rifles of the four manufacturers.4

The M14 was supposed to replace the M1, but also the BAR, carbine, and SMG. Until you see them side by side, most people assume the M14 was smaller than the M1. This “M14″ is actually a civilian Springfield M1A. (image: Rifle Shooter mag)..

In fact, only a few M1 parts are interchangeable with the M14, including most internal parts of the trigger housing group, and some of the stock hardware, A few other parts, like the extractor and rear sight aperture, interchange but aren’t quite “right.” (The M14 extractor works better in either rifle; the M1 and M14 sights are calibrated in yards and meters respectively).5

The M14 had a short life as a US service rifle, and a controversial one. (Congress, for one, couldn’t believe the amount of money that had been spent for a relatively marginal improvement over the M1). But it has had a long afterlife as stuff of legend. And this where Loose Rounds’ most recent effort in mythbusting comes in. Here is a taste:

Go on to any gun forum, and it won’t take you long to find people willing to tell you how great the M14 is. How accurate,like a laser, tough as tool steel with no need to baby it or clean it. powerful as a bolt of lightening, and how well loved it was by those early users who refused the M16 because they wanted a “real” weapon made of wood and steel…. .. But, is all that really true? Maybe it is a triumph of nostalgia over common sense and reality. One truth is, it was never really liked as much as people think they remember.

The M14 was having major problems even before ARPA’s Project AGILE and a Defense comptroller reported the AR15 superior to the M14;the famous Hitch Report stating the AR15 , the M1 and the AK47 superior.

(Loose Rounds then quotes those exact conclusions from those reports, which are also referenced in many of the Sources we list at the end of this document).

My own Father had this to say. Dad was in Vietnam from 67-68 in the 4th Infantry Division.

“I liked the M14 in basic, It was the first semi auto I had ever fired. It got old carrying all that weight fast running every where all day and night. I qualified expert with it. Once I was issued an M16 right before we over seas, I never looked back.”

For every person who has told me how great the thing is, I have found two who had nothing by misery and bad experiences from it. I myself among them.

…

The M14/M1a will be around for as long as people will continue to buy them. Certainly there is nothing wrong with owning them liking them and using them. By no means is it useless or ineffective. But its legendary reputation is something that needs to be taken with a grain of salt and careful study of the system if you intend to have one for a use your like may depend on.

If you are curious posts on shooting rack M14s and custom service rifle M14s with Lilja barrels fired at 1,000 yards can be found here on Looseorunds using the search bar. There you can read of the M14/M1A compared against the M1 Garand and M1903.

When we sat down last night to start writing this, we were going to analyze their post in great depth, but we can only suggest you go Read The Whole Thing™. The M14 is very beloved, but then, many soldiers come to love their first military rifle quite out of proportion to its qualities. (Indeed, we feel that way about, and retain a limerent attachment to, the M16A1, while recognizing that progress has left the original Army M16 behind).

If nostalgia drives you, LRB has this rifle on a new T44E4 marked receiver in stock — for nearly $3k. We want it but not $3k bad!

Indeed, there is a space on the gun room wall marked out for an M21, sooner or later. But that;s where it is likely to stay most of the time. (Shawn’s post at Loose Rounds has some details about the fiendish difficulty of keeping one of these in accurate shooting trim).

Notes:

- Stevens, North American FALs, p.106; Iannimico, p. 62.

- Iannimico, p. 59.

- Stevens, US Rifle M14, pp. 197-224l

- Emerson, Volume 1, pp. 41-70

- Emerson, Volume 3, pp. 129-130.

Sources

Emersom, Lee. M1 History and Development, Fifth Edition. (Four Volumes). Self-published, 2010-2014.

Iannimico, Frank. The Last Steel Warrior: US Rifle M14. Henderson, NV: Moose Lake, 2005.

Rayle, Roy E. Random Shots: Episodes in the Life of a Weapon Developer. Bennington, VT: Merriam Press, 1996.

Stevens, R. Blake, North American FALs. Toronto: Collector Grade Publications, 1979.

Stevens, R. Blake, US Rifle M14: From John Garand to the M21. Toronto: Collector Grade Publications, 1979.

Ghost Gunner Update — Received 26 January

Everyone who ordered one of these should have gotten this update. It’s shared here for those of you who are just curious, not committed. Consider it a Guest Post by Cody R. Wilson. -Ed.

Hey Ghost Gunners. Time for a production update.

We spent the first week of January correcting our enclosure provider’s specification errors, to eventual success. We then proceeded to junk 1200 pounds of powder-coated steel. And yes, they ate the cost.

We began to suspect this supplier’s abilities at the end of the year, however, and were able to bring on a more reliable and professional supplier in Austin to replace this work and make up for time lost on enclosures.

So, as it stands today, we think we’re only going to be shipping about 18-20 machines this month. Our new supplier should get our part stream way up in February, and most people should see their GG in the mail in as soon as three weeks. To you backers who were expecting Holiday delivery, I can only thank you for your patience and promise you a valuable product.

To you on the wait list, I will be able to call up 40 to 50 of you once we ship the first 100 machines through February. You’ll receive an email from DD.

There is still a lot to discuss from this month, however.

Yes, we’ve been hard at work making the guts of nearly 300 machines so far. We’ve been afforded extra time in the delays for software adjustments and V&V on our custom electronics (more about those when the occasion is happier).

We’ve staffed up enough to have people in the shop around the clock, but this is still not what we need to talk about.

We should talk about ATF 2015-1.

The first week of this new year, Obama’s Justice Department, through his ATF, gutted the traditional trade in 80% lower completion. It doesn’t matter what their story is, the move was made to destroy 50 years of industry precedent and squeeze you out of access to commercial grade CNC equipment to privately, and I should add constitutionally, equip yourself with your own AR.

Now, this new ATF regulation does not affect your purchase of this machine and our ability to sell it to you. Indeed, the Obama Administration has just made this Ghost Gunner endeavor in which we’ve all joined extremely important. As of January, the only way you can use CNC to finish your lower is to buy a machine. Your absolute government knows most law-abiding people cannot afford their own CNC, and so they have forced you to rely on hand tools if you want a private AR-15.

But now the world has a Ghost Gunner.

This month, Come and Take It Texas demonstrated one of our first production machines at the Texas State Capitol to welcome the new legislators.

The responses from the open carry groups were meek and anxious.

So let’s be very clear.

This project and our company are about expanding your franchise as freemen. And in the face of overwhelming opposition. Your governors, legislators, lobbyists and industry friends do not give a damn about your right to have this rifle outside of commerce and surveillance.

The Feds are doing everything they can to stop this project. Just this week we received a contemptuous letter from DoD denying cognizance of our technical data requests, and late last year we were threatened directly by the DTSA.

I say all this to say that we are serious. The enemy will do anything to stop this and they are doing it, and we are trying with all of our might to ship these machines and their software to you. It is the only thing any of us are doing, and though the pressure feels enormous I am thankful to have the opportunity to deliver this tool to you.

***

There is a volume of information I want to share about DD’s ongoing battle with the Obama regime. And I promise disclosure of this information after we begin shipping GG’s in quantity. You should know specifically what your government thinks of you and your First and Second Amendment.

Machines incoming!

He’s Feeling Gladius All Over

OK, now that we’ve shown our age with a pop-music pun that 90% of the audience will not get, we want to send you to the imgur link where Sir Keyboard Commando, whoever he may be, converts this piece of steel stock:

…to this replica of a Roman gladius, the short sword of the legions.

SKC made the sword from 1075 steel alloy by, essentially, cutting away everything that didn’t look like a Roman sword.

The page shows a photo essay of the whole process:

- laying out the outline with machinist’s layout die and a scribing tool;

- cutting the shape with a bandsaw;

- grinding to section;

- draw-filing to a smooth, ripple-free surface;

- heat-treating in a homemade furnace;

- quenching;

- tempering in a kitchen oven.

And best of all, he can say, “I made it myself!”

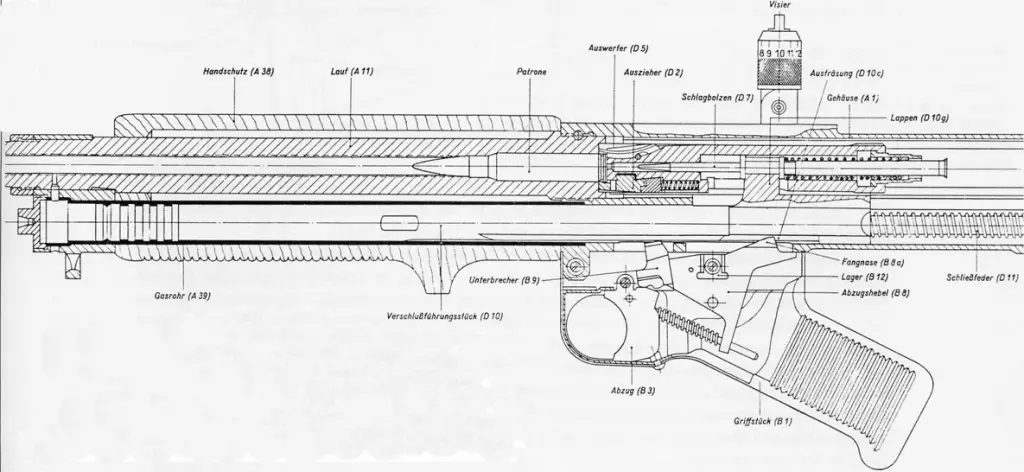

How Did the FG-42 Selector Work?

We were asked that yesterday and we pontifically pronounced, “it fired from the open bolt in automatic mode, and from the close bolt in semi.”

Then we rested back on our laurels as Gun Expert and —

“Well, how did they make it do that?”

“*!” Hmm… How did they? “Let me get back to you on that.”

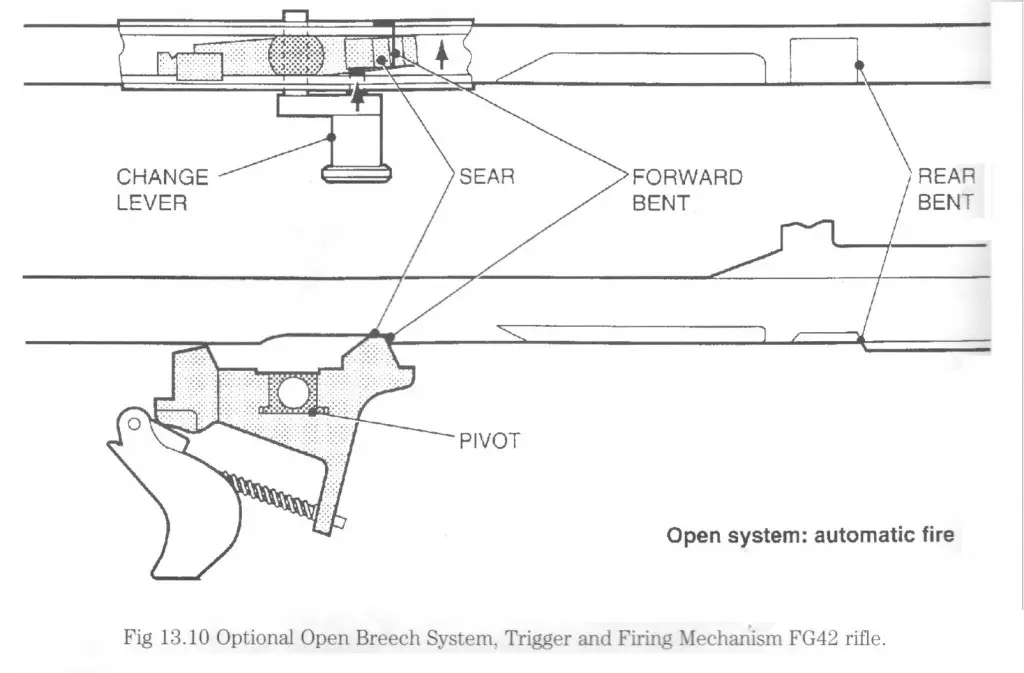

Fortunately, several references on the shelves explain it in terms our walnut sized brain could grasp. It turns out it was very simple, when you consider how complex some of the other design options made the FG. And it imposed some trade-offs, costing the rifle significant semi-auto accuracy as the price of that mechanical simplicity. Let’s walk you through it.

It worked exactly the same on the First and Second model of the FG, by the way; so we will use images of both in this post.

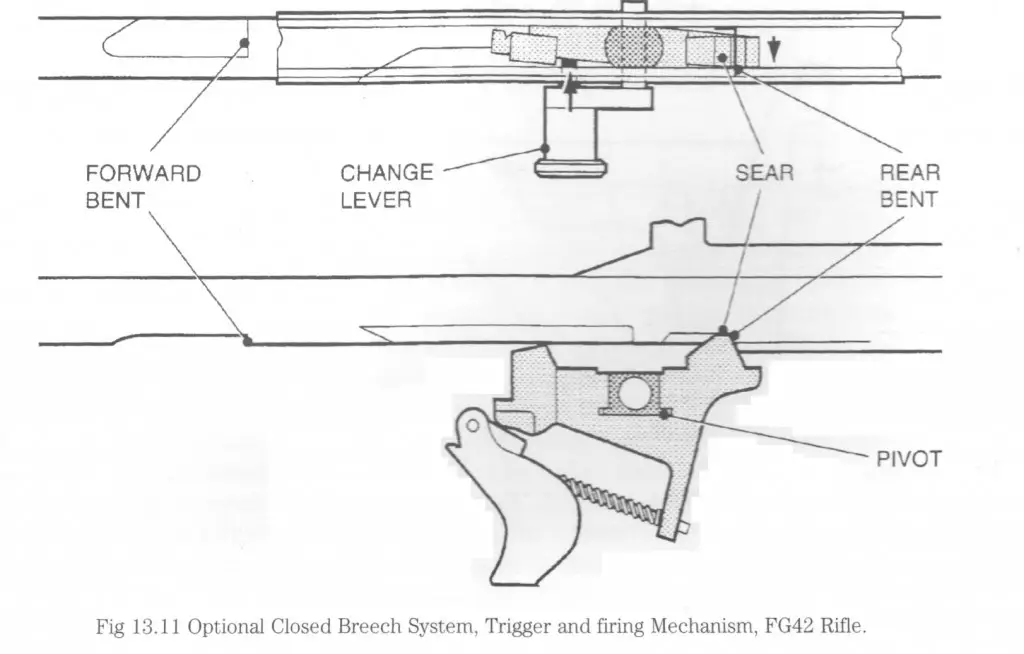

This image is from a crudely DEWATted Second Model FG that was examined by Forgotten Weapons. There’s a great set of images there, and the gun’s internals are mostly present and correct.

The selector switch is on the left side of what we’d call the grip frame. (The German manuals call this part the Lager which can mean holder or receiver, too, but we’ll stick with “grip frame”). The selector swings through 180º of travel; knob forward covers an “E” for Einzelfeuer (“single fire,” semi-auto), and knob rear clicks on to “D” for Dauerfeuer, (“continuous fire,” automatic). Note that the letter that shows is the antonym of the function you get. Don’t ask us; Hermann Göring was not available to take complaints.

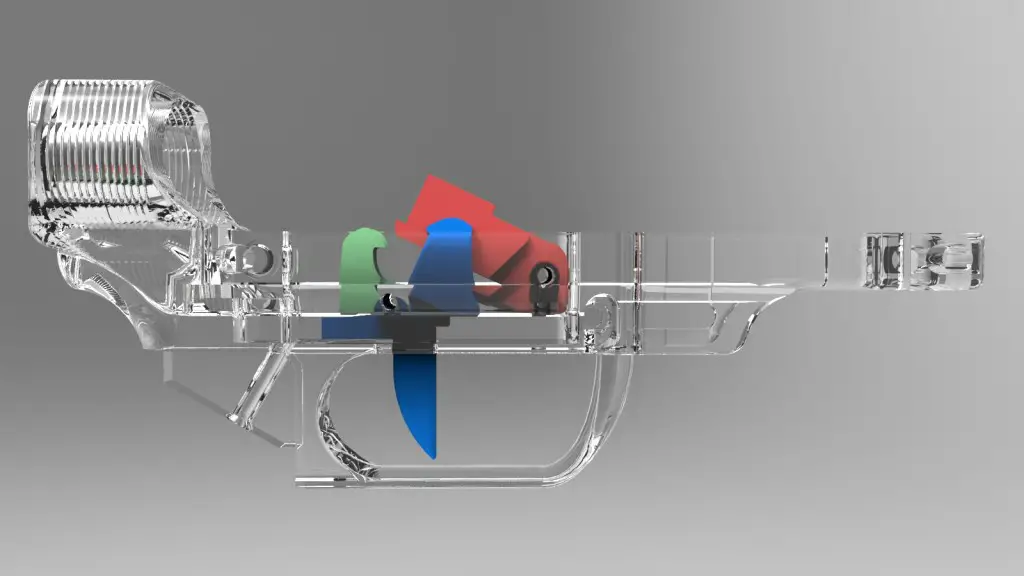

Comparing the Bedienungsanleitung (manual) image of a First Model to the photo of the second model above that, we can see how the trigger works. The trigger pivots on a pin forward of, and slightly below, the selector switch. The axis of the selector switch is also the axle of the sear (in the diagram, Part B8 Abzughebel, literally “trigger lever”). The sear nose (Fangnase, “catch nose,” B8a) is the hardened end of the sear that engages a notch (if you learned engineering English in Britain, a “bent”) in the operating rod (Verschlußführungsstück, “bolt guiding piece,” Part D10).

There are, however, two notches in the op-rod. One is towards the front end, and mostly right of center. One is towards the tail end, and mostly left of center. You can make out the two notches in this Forgotten Weapons photo.

Rotating the selector moves the sear laterally either right to align with the front-end notch, or left to align with the tail-end notch. If it aligns with the tail-end notch, a disconnector (Unterbrecher, literally “interrupter”, B9), works by disengaging the trigger from the sear until the trigger is released (i.e., normal semi-auto trigger reset). Thus the selector engages the sear nose with either the nose-end notch, which holds the op rod and bolt assembly to the rear, or the tail-end notch, which holds the op rod and firing pin only to the rear, allowing the bolt to lock fully into battery.

Rotating the selector moves the sear laterally either right to align with the front-end notch, or left to align with the tail-end notch. If it aligns with the tail-end notch, a disconnector (Unterbrecher, literally “interrupter”, B9), works by disengaging the trigger from the sear until the trigger is released (i.e., normal semi-auto trigger reset). Thus the selector engages the sear nose with either the nose-end notch, which holds the op rod and bolt assembly to the rear, or the tail-end notch, which holds the op rod and firing pin only to the rear, allowing the bolt to lock fully into battery.

Releasing the trigger releases the op-rod, then. If the weapon is on full automatic, the bolt and op-rod come forward, the bolt locks, the op-rod finishes its full travel, and the firing pin initiates the cartridge. The whole thing cycles again and continues to do so until the operator releases the trigger. When he does, the bolt is held in automatic battery — to the rear.

These schematics are from Allsop & Toomey’s Small Arms, pp. 226-227. The depiction of the selector in these drawings is how we came to understand that the selector (“change lever” in British English) covers the appropriate letter for type of fire selected.

If the weapon is on semi (selector knob swung 180º to the front), the trigger releases the op-rod, which brings the firing pin down on the primer. The bolt then cycles, but returns to semi-auto battery, closed bolt on a live cartridge, regardless of trigger position. The disconnector rides in the notch forward of the rear notch (here “bent”) only to disconnect when in Semi.

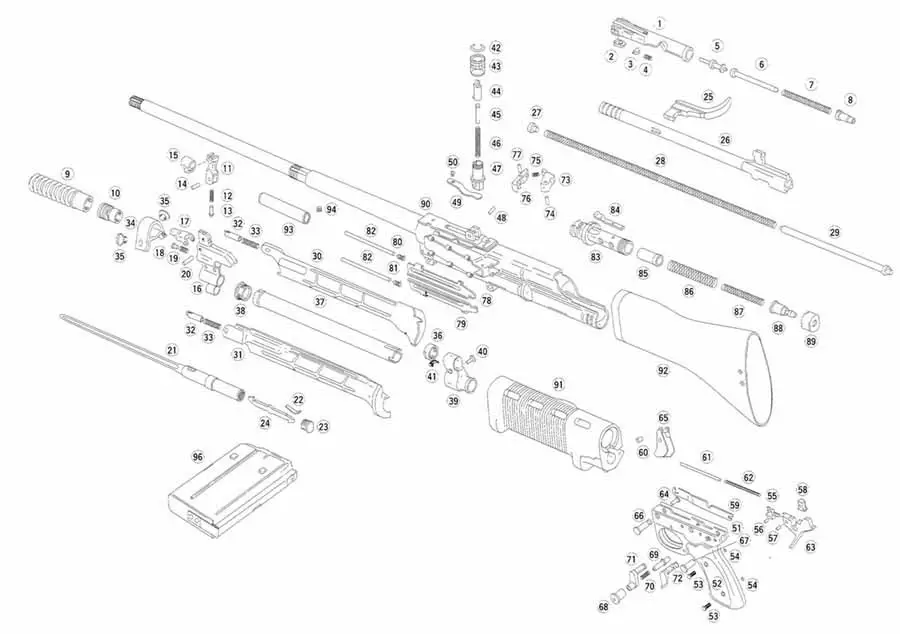

If you’re feeling envious of FG-42s, you can buy an excellent semi repro from SMG Guns, you can pay more than a new luxury car for a transferable, or you can take the following image, a pile of steel, wood and aluminum, and a set of files and try to do what SMG did:

It may take a while. Best of luck to you!

Now, the FG42 wasn’t the last word in open/closed bolt hybrid firing mechanisms. As mentioned, having the whole op rod and firing pin move was inimical to accuracy. This not only increased the motion of the firearm on firing, but it increased lock time substantially, giving that motion more time to work on sending your projectiles wild. But that was a tradeoff that designers at Rheinmettal accepted for their simple and reliable open/closed bolt mechanism.

As we’ve seen, waste heat is a real killer of combat weapons in automatic fire, and by extension, a potential killer of the men who fire them. Firing from an open bolt reduces the incremental temperature increase per automatic round fired, by allowing more air to circulate and more of the potential radiative area to be exposed to ambient-temperature cooling air. This has the side effect of moving the critical temperature area or point further up the barrel from its usual position 5 to 8 inches in front of the chamber.

Firing from an open bolt also prevents cook-offs. Contrary to common misconception, cook-offs are usually not instantaneous but result from a round remaining chambered in a hot barrel for some seconds or minutes. For a cook-off to be instantaneous (and risk an out-of-battery ignition) the temperature has to be extremely elevated. For a routine cook-off, which can take some time to happen, the biggest danger is that no one is expecting the weapon to fire, and people may be in an unsafe position forward of its muzzle at that point.

The FG42 was a remarkably good weapon, like many WWII German weapons. Not good enough for them to win the war, fortunately; it was the very devil to produce (ask Steve at SMG!) and was produced in the sort of numbers that would be a rounding error, or the scrappage involved in training some new line workers, in American, British or Russian production. The US produced, for example, about 40 times as many BARs as Germany produced FG42s; Russian production of the pan-fed DP28 LMG was easily double that. (German production wasn’t as dismal as you might think. They produced more rifles and carbines of all types than the USA did. But they did have a tendency to engineer something very good, and then fail to build it in numbers that would make a difference).

A Taxonomy of Safeties

There are several kinds of safeties that are used on service weapons to ensure that only the proper and deserving people are shot. They generally interface in some way with the firing mechanism of the firearm. They may act on the trigger, the hammer or striker, or the sear, or (in some fiendishly clever arrangements) more than one of the above. It is generally thought better to positively lock the striker or firing pin than merely to lock the sear or trigger. If the mechanism fails due to parts breakage, it is easier to design a fail-safe mechanism if the striker or firing pin is immobilized.

Safeties Classified by Operator Volition

Safeties can be classified based on the degree of volition required to use them. An applied safety must be consciously put on, in most cases. An automatic safety is unconsciously applied as the pistol is taken up. Examples of automatic safeties include:

- the Glock Safe Action trigger and its many copies and derivatives;

- the grip safeties characteristic of many Browning designs, such as the M1911 .45 and the FN M1910 pocket pistol;

- similar grip safeties on open-bolt submachine guns such as the Madsen and the Uzi. (An open-bolt SMG poses peculiar safety problems);

- transfer-bars and other means to ensure a weapon can’t fire unless the trigger is pulled;

- mechanisms that hold a firing pin back until a weapon with a locking breech is fully in battery (the disconnector often does double-duty as this part);

- Firing-pin immobilizers as in the Colt Series 80 and newer M1911s (an earlier firing pin safety, the Swartz Safety, was used in commercial Colt 1911s from circa 1937 to 1940, and is used by Kimber today);

- A heavy, smooth trigger pull such as that on a traditional Double Action revolver or a DA/SA autopistol can prevent unintentional discharges. However, some heavy triggers (like the Glock NY2) have a bad enough effect on accuracy as to threaten bystanders with unintentional shooting.

- Magazine safeties, an obsolete European concept;

- Half-cock notches (in British/European English usage, these may be called half-cock “bents.”)

Contrasting with these automatic safeties, that do their work without conscious application by the operator, there are Applied or volitional safeties. Applied Safeties are usually classified by what part of the firing mechanism they work on, and so examples of Applied safeties break down into:

- Safeties that lock the trigger. The simplest of these are the crude trigger-blocking safeties on an SKS or Tokarev SVT. More complex trigger-locking safeties are found in the AR series of rifles and the FN-FAL;

- Safeties that lock the firing mechanism (which may be further divided into those that lock the firing pin, like the Walther P.38 or Beretta M92, and those that lock the hammer, like the US M1 Rifle, or

- The bolt holding notch in many 2nd-generation submachine guns. (These are reminiscent in a way of the safety of the Mosin-Nagant rifle, which requires the cocking piece to be rotated and caught in a notch). The case can be made that this is a firing mechanism lock, because the bolt with its fixed firing pin is the firing mechanism.

- Safeties that lock the sear. Examples include the .45 M1911, its younger brother the BHP, many other auto pistols, and most general purpose machine guns. Some require the weapon to be cocked to lock the sear, others allow locking the bolt forward (the RPD LMG and the Sterling SMG are examples of this).

- Safeties that disconnect the trigger from the sear. This is found in the Bren gun and many other Czech designs, historically. The ZB 26 and its derivatives were quite cunning: in one position, the selector brings the trip lever to engage the semi notch, which is in the upper side of a window in the sear. In the other position, it engages the auto notch in the lower side. In the intermediate, “safe,” position, the trip lever clears both notches and the weapon does not fire.

Note that automatic safeties, too, can be broken down as working on the trigger, the firing mechanism, and the sear, also. So safeties can also be Classified by Operation.

Safeties Classified by Operation

It is possible to classify safeties in the first place by their means of action:

- Trigger safeties

- Firing-mechanism (striker, hammer, firing pin) safeties

- Sear safeties

- Disconnecting safeties.

This is true, obviously, for both automatic and volitional safeties, and classifying them this way puts their mode of action forward as more important than their mode of engagement, which (applied/volitional or automatic) becomes a secondary trait.

One More Trait: Must the Firearm be Cocked?

It is only possible to engage many safeties when the weapon is cocked or ready to fire (presuming a chambered round). Familiar examples include the AR series rifles and the 1911 pistol and other Browning hammer designs. Other safeties engage regardless of the energy state of the striker or hammer, for example the AK, the Remington Model 8 (a Browning-designed trigger mechanism that was deeply influential on 20th and 21st Century firearms designers, including Garand, Kalashnikov and Stoner), and the RPD light machine gun.

Combination Safeties

While a weapon may have multiple safeties that do different things (or multiple modes that engage the same safety, as in the safety lever and grip safety of early Lugers), it’s possible for a single cunningly-designed safety to disable multiple points of the firing chain at once. For instance, the Lee-Enfield safety is a model of versatility: it locks the striker, locks the bolt closed (preventing the chambering of a round), and disconnects the striker from the sear. The M1911 or Browning High-Power safety locks the slide closed as well as locks

It’s also possible for a volitional safety to be combined with other functions. The most common example of this is the combined safety/selector switch of most modern assault rifles, like the M16 or AK-47.

To Sum Up

There are a great but finite number of ways to design safety features on modern firearms. Careful study of prior art allows today’s designer truly to stand on the shoulders of the giants in the field. John Browning left no memoir or technical book, nor did John Garand, John D. Pedersen, Gene Stoner; and the many memoirs of Mikhail Kalashnikov are disappointing to the technical reader. But each of these geniuses spoke to us in the art of his designs, and they are still available for us to study and to try to read what their art is trying to tell us.

We have not, in this limited post, attempted to discuss “best practices” or the pros and cons of any individual safety design. Very often, the designer will be limited by the customer’s instructions or specifications. (For example, the grip safety of the 1911, which 1970s and 80s custom smiths often pinned in engagement as a potential point of combat failure, was requested of John M. Browning by the US Cavalry. The other military branches didn’t feel such a need, but the horse soldiers did, and Browning first added it on his .38 caliber 1902 Military pursuant to a similar request). Thus, even as a designer, your safety design decisions may not be your own.

Notes and Sources

- This post has been modified since it was first posted, to expand it.

- This post will be added to The Best of WeaponsMan Gun Tech.

This post owes a great deal to the following work:

Allsop, DF, and Toomey, MA. Small Arms: General Design. London: Brassey’s, 1999.

Chapter 13 is an extensive review of trigger mechanisms, including safeties, and while their classification of safeties is different from ours, their explanations are clear and concise.

Thanks to the commenters who not only recommend this long out-of-print book, but also sent us a link to a bookstore that had it (it’s a copy withdrawn from a military library, as it turns out). This out-of-print work is less technical and deep, but considerably more modern, than Balleisen; its examples are primarily British.

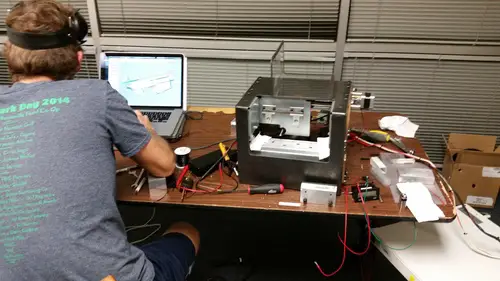

GhostGunner Update

It looks as if Defense Distributed’s original intent, to ship the initial batch of GhostGunners by Christmas, ran into the buzzsaw called reality, and the machines did not ship on time.

The [GhostGunner] team worked all through December to begin fulfillment just before Christmas Day, but due to two of our US suppliers missing their original and revised December delivery deadlines, we have been at the mercy of factors outside of our control.

The bottleneck came down to our steel enclosures.

Though we are now delayed over ten days in our internal shipping schedule, we are fully prepared to begin fulfillment when we receive sufficient enclosures, which should be as early as the first week of January.

It’s not ideal news, but we are fully staffed for final assemblies and have run a really great catchup game in our V&V.

The delays have allowed some improvements to the machine. They’ve brought circuit-board production in-house:

Final GG software testing continues uninhibited and we’ve established our own board production to cut even more costs.

This presumably means their own GrblO (pronounce “garble-oh!”) board, And, perhaps more usefully for end users, the machine will ship ready to handle 80% lowers that do not have the rear pocket milled out, as well as the ones that do. As late as November 2014, they were still saying that only the lowers with the pockets milled out would work.

Unlike every other technology firm, they can’t put their software or firmware on the web, and they can’t even post their user manual.They have run into difficulties, not unexpectedly, with the various Fed agencies that are supposed to license technology “exports,” which theFed defines as having happened when you put software on the Internet.

At least one GhostGunner did make it into private hands, in Texas, where it showed up at a demonstration at the state Capital. Guns.com has a full report, complete with video, but we thought these quotes from Cody Wilson show that he’s playing a somewhat different game than your average entrepreneur:

I thought CATI [Come And Take It Texas] demonstrated the machine, and presented themselves, like men truly jealous of their Liberty.

As for my own objectives, if I can’t get you to stop asking permission from your Government, I can at least demonstrate its overcoming at its front steps.

Food for thought, that.

Personally, we just think a programmable, highly-rigid, easily fixturable and open-source CNC endmill has a lot of uses around here. Our revolution is a technological, not political, one. But freedom is the greatest and yet, the least harmful, of intoxicants, is it not?

“The Gun is its Own Tool Kit.” — Browning ANM2

One sign of a gun design that is not completely thought through is a requirement for special tools for disassembly. These days, most guns are designed for disassembly without any kind of offboard tools. But this was not always the case. John M. Browning was one of the first designers to consistently design guns to be disassembled without anything special. And it was a bit of a marvel, as the tone of this excerpt from a naval aerial gunner’s manual called This is Your Gun reveals:

One sign of a gun design that is not completely thought through is a requirement for special tools for disassembly. These days, most guns are designed for disassembly without any kind of offboard tools. But this was not always the case. John M. Browning was one of the first designers to consistently design guns to be disassembled without anything special. And it was a bit of a marvel, as the tone of this excerpt from a naval aerial gunner’s manual called This is Your Gun reveals:

THE GUN IS ITS OWN TOOL KIT

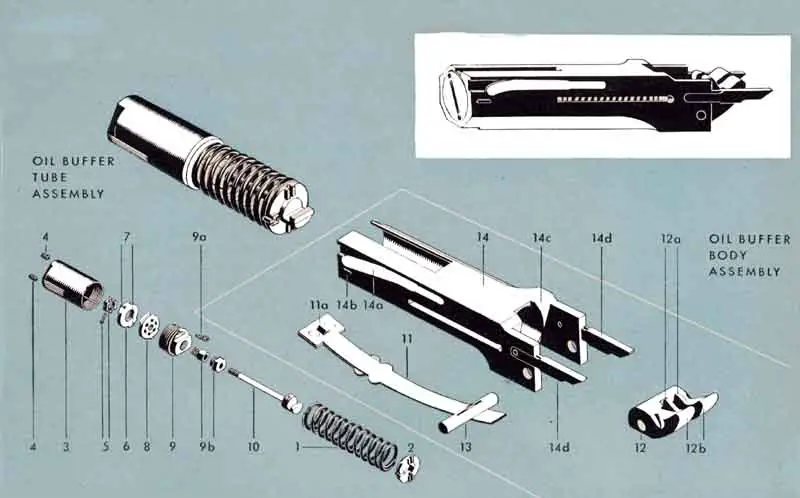

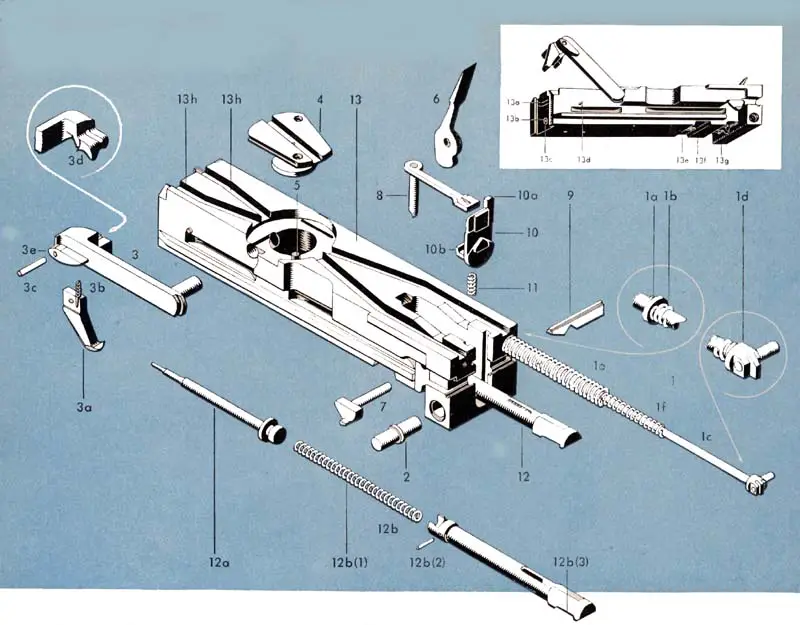

In an emergency, the gun can be stripped with nothing but its own parts as tools. Use the point of a cartridge or the cocking lever pin to depress the oil buffer body spring lock.

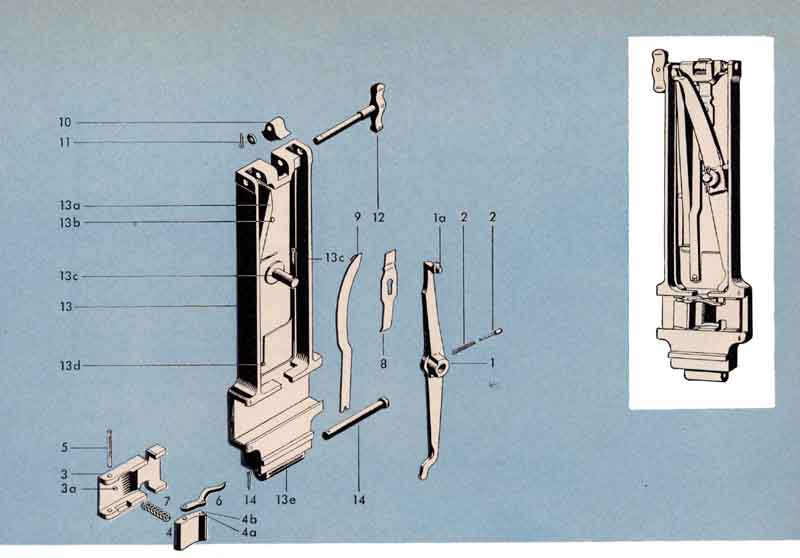

Key parts in the oil buffer assembly: Oil Buffer Body Spring Lock (14a); Accelerator Pin (13), Accelerator (12). Oil Buffer Tube Lock (11)

Use the cocking lever pin to drift out the sear stop pin and accelerator pin.

Many of the parts mentioned are in the Bolt Group. In the order that they’re mentioned: The Cocking Lever Pin is Nº 7. The Sear Stop with the Sear Stop Pin is Nº 8. The Cocking Lever is Nº 6.

Use the flat tip of the cocking lever as you would use a screw driver to remove and replace the sear stop, oil buffer tube lock, the cover latch spring, and cover extractor spring. Use the oil buffer tube lock to pry the handle of the trigger bar pin out of its hole in the side of the receiver.

Use the sear stop pin to drift out the belt feed pawl pin.

The Belt Feed Pawl Pin is #5 in this illustration. Cover Latch Spring is #8, Cover Extractor Spring #9. US Navy.

But use these methods only when absolutely necessary and take care not to damage the parts used as tools. Never use the driving spring rod assembly as a tool.

Conversely, having a gun like this that can be disassembled and reassembled in field conditions without a bench full of tools is a marker of good design. This kind of design is more commonly encountered now than it was in Browning’s day, which speaks for Browning’s lasting positive impact on firearms design.

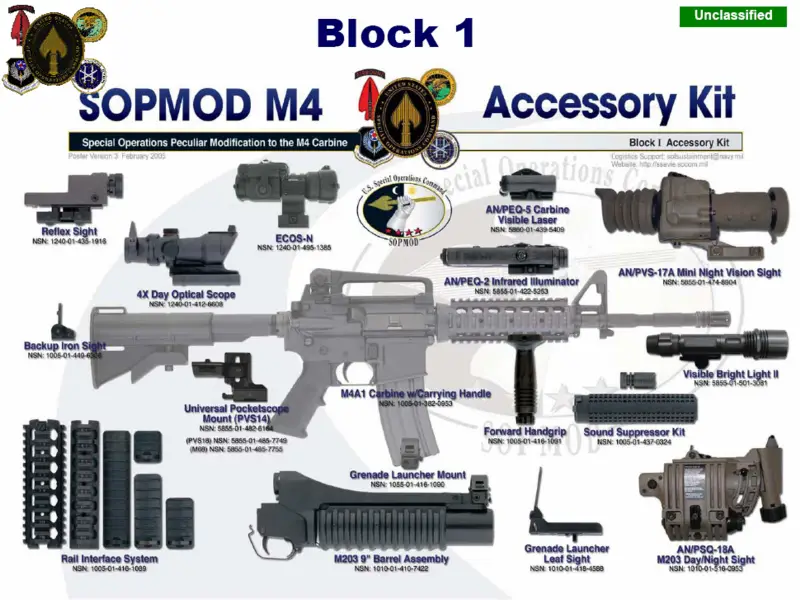

Mike Pannone: Making an M4 Run like a Gazelle

This article has been around for years, but it’s still worth reading. Mike Pannone is a fellow 18B and someone with nearly immeasurable M4 experience. He was an instructor for, and one of the designers of, AWG’s combat shooting school, which prepared a lot of guys for successful combat in Iraq and Afghanistan. A friend who was the SJA at AWG raved about that course. Mike is pretty well known in the shooting and training community.

Mike has very extensive comments on the M4 at Defense Review, which stem initially from a discussion of fouling. We’ll just quote his conclusions from this piece below, and also recommend his article on reliability issues, and his follow-up on diagnosing the root cause. Conclusions from what we suppose you could call the “fouling piece“:

Fouling in the M4 is not the problem. The problem is weak springs (buffer and extractor), as well as light buffer weights (H vs. H2 or H3). With the abovementioned drop-in parts, the M4 is as reliable as any weapon I have ever fired, and I have fired probably every military-issue assault rifle fielded worldwide in the last 60 years as a Special Forces Weapons Sergeant (18B). An additional benefit of the heavier spring/weight combo is that it transmits the energy impulse of the firing cycle to the shoulder over a longer duration, lowering the amount of foot pounds per second and dramatically reducing the perceived recoil. Follow-on shots are easier to make effectively, and much faster, especially at 50 meters and beyond.

I reliably fired 2400 rounds (80 magazines) on a bone dry gun, and I would bet that is a lot more than any soldier or other armed professional will ever come close to firing without any lubrication whatsoever. So, disregard the fouling myth and install a better buffer spring, H2 buffer, enhanced extractor spring and a Crane O-ring (all end user drop-in parts). With normal (read “not excessive”) lubrication and maintenance, properly-built AR-15/M4 type rifles with carbine gas systems will astound you with their reliability and shootability.

There is a great deal more to the article than that; we just gave you a little bit. (For example, if you read the whole thing, he provides the sources for the upgraded parts he uses).

Mike’s articles are collected at the CTT Solutions website, although the articles link back to DR.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.