From time to time, people, especially young people, ask this question. We’re not gun design engineers, although we’re fascinated by their work; we’re, relatively speaking, dilettantes.

From time to time, people, especially young people, ask this question. We’re not gun design engineers, although we’re fascinated by their work; we’re, relatively speaking, dilettantes.

So when we got a chance to see a real job listing for a real senior design engineer to do real firearms design, our first thought was to share it with you guys and gals. (Well, actually, our first thought was… “Crap. We’re not remotely qualified.” But our next thought….) Anyway, here is the list of prerequisites:

Education and Experience Requirements

- Four year degree in physical engineering required. Mechanical engineering preferred.

- 5 plus years related experience in an engineering environment required. Manufacturing environment preferred (firearms manufacturing is ideal).

- Duties require effective verbal communication skills, visual acuity to product details along with drawings and computer screen data, and the physical ability to work and move in a factory environment.

- Firearm Design Experience Required

- Ability to work cross-functionally internally and externally.

- Knowledge/experience with SolidWorks CAD system preferred.

The job is with a large, publicly held company (Vista Outdoor, the sporting spinoff of ATK), and the benefits package seems decent. Note that they don’t want an operator-boperator, gun-plumber, or machinist. They want a design engineer who can work on the screen and then go on the shop floor to find out why the parts don’t match the computer file. “SolidWorks preferred” but we bet if you came from a CATIA shop they’d still snap you right up if you met their other prerequisites.

Note that they’re looking for a degreed engineer, but not a PE. That should help narrow down what they’re planning to pay for this guy.

What will a Senior Firearms Design Engineer be doing? Here’s what the listing says:

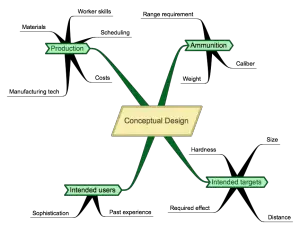

Responsible for the design and development of new firearm products. Duties include development of concept print/plans, design of products, tolerance specification, and other similar duties pertaining to product design.

What about some specific duties?

- Develop and design new company products.

- Develop and produce concept prints, plans, drawings for new products and/or modifications/enhancements to existing products. Design features and functions for the products.

- Specify materials, dimensions and tolerances, inspection standards, etc. for the components and parts.

- Develop details drawings.

- Oversee and guide projects assigned to less experienced design engineering personnel.

- Keep abreast of developments in the market. Review competitor’s designs and products.

- Analyze market place requests, customer requirements, etc.

- Analyze company ability and desire to meet requirements and/or requests and make appropriate recommendations to management personnel.

- Maintain a working liaison with other departments and engineering sections. Provide support for sales personnel to contribute technical assistance to customers.

- Assist QA personnel provide technical support for vendors, develop inspections for parts, and/or to qualify vendors.

- Work with other engineering units to resolve problems, develop processes, etc.

- Perform other similar duties as required by responsibility or necessity or as requested.

The downside? Well, it is at Savage in Westfield, Massachusetts; there are nice places to live around there (apart from the politics and outside the inner city, it’s Norman Rockwell’s America) but it’s a very expensive place to live, with staggering taxes; and MA is a Brueghelian environment for a gun guy these days. (And it gets worse every time the gun control pols’ constituents shoot each other up in Roxbury and Mattapan).

The downside? Well, it is at Savage in Westfield, Massachusetts; there are nice places to live around there (apart from the politics and outside the inner city, it’s Norman Rockwell’s America) but it’s a very expensive place to live, with staggering taxes; and MA is a Brueghelian environment for a gun guy these days. (And it gets worse every time the gun control pols’ constituents shoot each other up in Roxbury and Mattapan).

Three possibilities here: someone left Savage one key designer short, perhaps during last year’s layoffs; the company is about to get a bunch of investment earmarked for new products; or Savage managers see the opportunity to poach some talent from a struggling neighbor (cough Colt cough).

If the job sounds like it you want it, you’re qualified, and Westfield isn’t all that impossible for you (like, because you’re currently 40 minutes south in equally anti-gun Hartford?), then “apply online at www.vistaoutdoor.com to Job ID: 29438,” as the listing says.

Remember that a lot of the industry is located in anti-gun places, but it’s moving gunwards every year, and success in this job would open doors in many other manufacturing plants in our industry. (That’s one reason why you will always see competitors treating each other with regard and respect at industry shows — apart from the fact that gun folks tend to be polite folks. It’s a small industry, in people terms, and yesterday’s competitor is tomorrow’s colleague).

Savage is also looking for a senior quality manager. We leave digging up the details of that job as an exercise for the reader.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

10 thoughts on “What It Takes to be a Gun Design Engineer”

Maybe things are different in the US, but in Australia Savage are known mainly for their workhorse bolt action rifles. Apart from their Accutrigger, which was a nice piece of work, I’m not aware that they’re particulalry into innovation, so I wonder what their design engineer would be designing?

They might have decided the same thing, and are looking for an innovator.

It’s a good thing they made the Accutrigger too, because the Savage I bought without it (it has since been replaced) had an absolute disaster of a trigger.

In the Jack Belk book we reviewed last week, he praises the Accutrigger as the best trigger on a mass-produced rifle, IIRC.

Hmmm…I had a Savage Model 93 rimfire in .17 HMR with an Accutrigger. It was damn good, particularly for a $300 rig (including an inexpensive Bushnell scope) which was all I could afford at the time. Then I found an Anschutz 1717 with the model 54 match action. I dunno if Annies qualify as “mass produced”, but that rifle has the best trigger I’ve ever pressed in 36 years of regular shooting with hundreds of different weapons. With Zeiss glass it will shoot single hole 5 shot groups at 100m all (non windy!) day long.

all those requirements are discriminatory: i want to be a weapons designer, so i should be given the position.

😉

You’ve got that all wrong, Red. Try this: “I have always identified as a firearms designer.” Worked the bomb for Rachel Dolezal, Elizabeth Warren, and an unknown quantity of yet-to-be-exposed phony minorities exploiting affirmative action!

I’m a firearms designer born in a Bubba’s body.

Really like Savage’s products.

Wouldn’t even visit Mass unless by boat where I can readily escape.

NO way I could reside there…well, actually not true; there are ways I could live there but some of the preliminary steps would be jailing EVERY person in state and most local government and repealing EVERY law enacted there after 1793.

***What It Takes to be a Gun Design Engineer***

It didn’t hurt either MikTim Kalishnikov or Georgy Shpagin that they were combat veterans of the Russian military, since their design output was intended for military usage. Master Finnish designer was a conscript veteran of the Finnish military 1918-1919, and Kijirō Nambu was a commissioned military academy graduate branched Artillery.

That said, neither John C. Garand nor John Moses Browning was a veteran of military/wartime service, though their designs clearly understood the users’ needs.

Hognose,

I am very happy to see you post items like this, mostly because if there were more information like this available when I was in my late teens I would have got to where I am now much sooner. (within weeks of sending tech branch two firearm products I’ve developed so that I can get a ruling on them and provide my customers with a product that I’ve tried to mitigate the risk of being declared illegal and seized from them)

It’s a truly amazing time to be involved in the STEM career fields, and it’s only going to get better!

Economic barriers to entry into the industry are crumbling much more quickly than even many of the optimists dared hope. This is due to a factor I’ve been aware of for quite awhile now that has been ignored when I’ve tried to bring to the attention of people involved with the defense world. A recent paper that is making huge waves in the maker community, and should be being discussed anywhere with even a little coverage of military technology, has now outed a thought provoking phenomena…. That phenomena being that open source hardware and software offerings have caught up to, and now surpassed in quite a few areas the capabilities the proprietary desktop manufacturing world has to offer.

The paper introduces us to the $7000 multifab 3d printer which boasts a staggering level of capabilities and versatility, so much so that to buy an equivalent closed source machine would be $250,000!

Notable capabilities, features, and performance numbers of the Multifab

1. It can print objects that require up to 10 separate materials in a single pass.

2. The actual different types of materials available for use in the printer is over 100 conservatively. New materials compatible with the design are coming out almost daily. Several things I’ve read lately make me think that one or more explosives have already been validated in stock or modified formulation for DLP or FDM printing (I’m betting on at least one IMX option in the mix)

3. 40 micron resolution: That is impressive on it’s own, but combined with number 4 makes the machine truly amazing

4. Closed Loop Control using machine vision technology

5. Upgrade agnosticism: Honestly, this feature alone makes the machine a superior option to the closed source walled garden systems touted as truly professional grade. With the phenomenal speed that things are proceeding at it’s pretty much guaranteed that as parts wear out you’ll get the signature joy of being able to increase the machines performance AND have suppliers COMPETING for your dollars… As opposed to calling the company who made your machine, and being gouged because “we haven’t made parts for that thing since ’08, if we do have one it’s not gonna be cheap. But we do offer an existing customer upgrade discount, and a substantial additional price reduction for customers with legacy platforms to trade up / in.”

Like it or not the future is here to stay no matter how much GDLS Lockheed Elcan Leupold and any number of other companies lobby to try and get it legislatively hobbled. More importantly though is that we the people make it clear that any such attempts will be seen as what they truly are. What they are is treason.

I have some other things that definitely need to be brought to the attention of the right people domestically, but not in an open discussion. I don’t want to give anyone who dislikes us, but hasn’t gotten the same insights even one extra day to utilize this.

Frankly I’m sure you have a very firm grasp on the implications of these developments, but in a very real way my resource availability, and general position in society provide opportunities for valuable insights.

I’ll put rogue techie and multifab in the subject line.