In 99 repeating 9% of gun barrels, the caliber is what it is, and the bullet that comes out of the barrel is the same diameter it always was, just marked by the rifling. Likewise, the rifling twist is what it is, and from the point where is picks up in the leade (forward of the chamber) to the point where the bullet exits the barrel it is constant.

Then, there are the exotics, the ones that keep 99.9% from closing the gap between there and “all.” We’re going to talk about one exotic bore, and one exotic twist, in a pair of posts: Squeeze Bore and Gain Twist. Even though the names sound dreadfully like 1970s NATO codenames for Russian anti-aircraft radars, they’re both really a thing.

Squeeze Bore

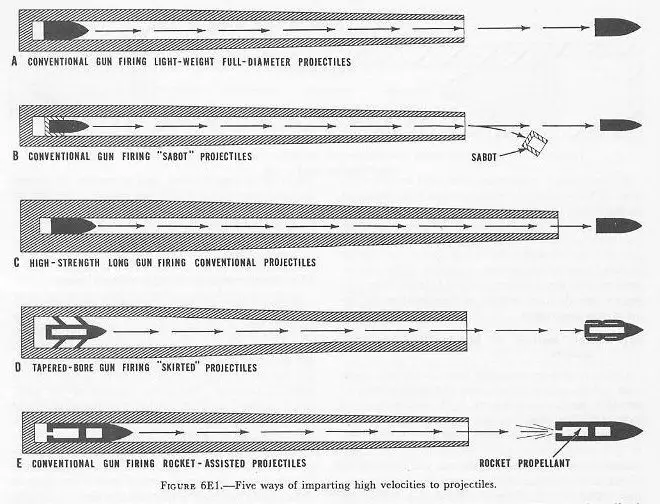

The idea behind squeeze bore is to use the power of the powder to forge the projectile down in diameter. This would, in theory, do one of two things: blow the gun to Kingdom Come, or accelerate the projectile to velocities previously unheard of. It didn’t take long for people to try to reduce this theory to practice. The 1957 edition of Naval Ordnance and Gunnery, Volume 1: Naval Ordnance, a training manual coded NavPers 10797-A, showed five different ways to get high velocities. The first is the familiar expedient of a lighter projectile, and the second, the saboted projectile used in most tank KE rounds these days, and in the .50 SLAP (saboted light armor penetrator) round. The third example, essentially beefing the gun up to take excessive pressures, doesn’t seem very practical, and the fifth was, in 1957, science-fiction stuff but is now a pretty routine way to get longer ranges in artillery. Which leaves the fourth example, D, our squeeze-bore

A very, very gradual and subtle version of squeeze bore is the choke used on some firearms. But there’s nothing subtle about true squeeze bore. The World War II German Pak 41 fired a Gerlich-designed 42mm projectile, which the barrel squeezed down to 30mm at the muzzle. At around the same time, the US developed (at Frankford Arsenal) squeeze bore M2HB barrels, which fired a special bullet that squeezed down from .50 to .30 caliber. These guns produced extremely high velocities, with kinetic energy and penetration to match.

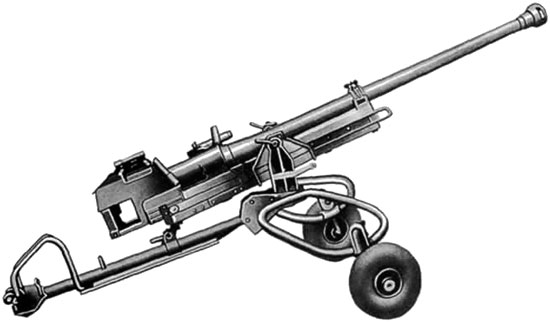

S.PzB.41 in action (or at least, being demonstrated). Wheels were removable to lower silhouette. Troops show scale… this is really small for something that can ding a JS-1’s frontal armor.

Squeeze bore was primarily used experimentally in antitank weaponry. The one weapon fielded with a squeeze bore was the German Gerlich S.PzB 41. The name Schwere Panzerbüchse meant, literally, heavy anti-tank rifle, and the Germans may have seen it as a replacement for the 7.92 x 94mm PzB 39, but its lightest variant weighed around 300 lbs. It could be broken down into smaller, man-portable-for-a-short-distance, loads.

Factory photo of the stripped-down paratroop version.

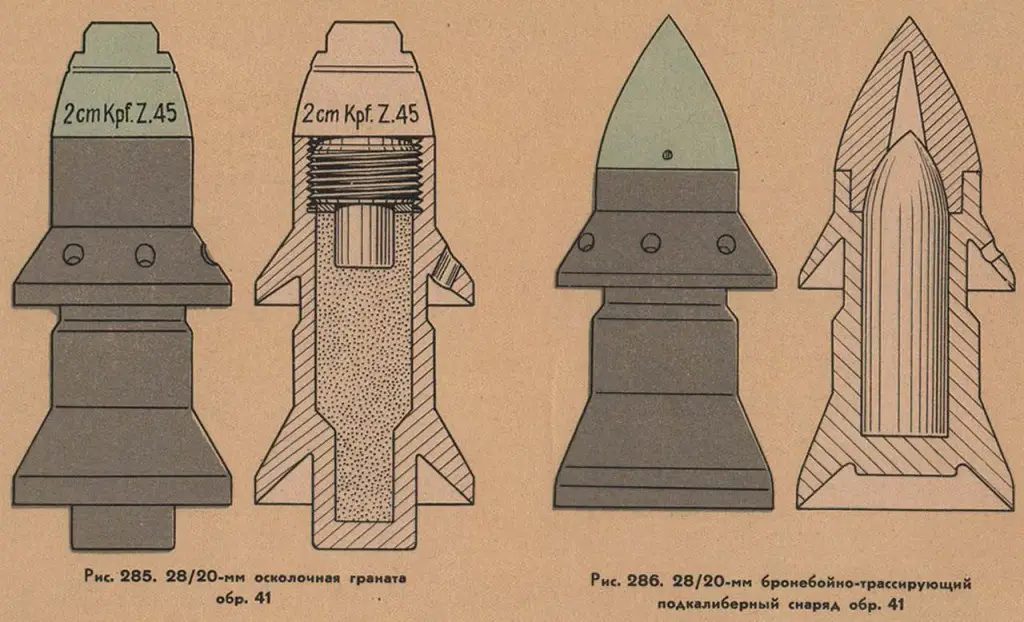

The effect can be approximated by firing an oversize cartridge in a smaller-caliber bore, if the throat or leade is not too tight. (If it is, you get a kB! instead). You’re more likely to get away with such an inadvertent bore squeeze if the projectile is highly malleable, like a soft lead bullet. The Gerlich system used a tungsten penetrator with an aluminum alloy jacket, including crushable skirts. The projectiles looked like this (HE/frag on the left, with a filler of phlegmatized PETN; AP with a tungsten-carbide penetrator on the right):

(source)

The S. PzB. 41 was very effective; at close range it could penetrate all mainstream Allied armor (even the KV-1 and JS-1 tanks), although its behind-armor effect was limited. The Germans were successful in making squeeze bores where other nations’ designers had failed. They mounted it on SdKfz.250 half-tracks and used it as a trailered, man-packed and airborne weapon.

A larger squeeze-bore, the Pak 41, was deployed in small numbers. The ammunition closely resembles the 28/20mm of the S.PzB.41 but is much larger: it started off at 75mm and squeezed down to 55mm. An intermediate sized version was a 4.2 cm (42mm tapering to 28mm) squeeze-bore version of the familiar Krupp 3.7cm light anti-tank gun. (German guns are described in centimeters — move the decimal point once for mm — and their squeeze-bores are known by their initial, not squeezed, caliber).

Making a tapered or “squeezing” rifled bore is a challenge, if you think about it, and conventional methods of rifling such as buttons and broaches don’t adapt well to it. (Cut rifling does adapt, but at a price in complexity. But the German invention of hammer-forging barrels over a mandrel opened up mass production to squeeze bore in German plants. (A microscopic amount oftaper is usually used in hammer forging, to facilitate mandrel removal. But the amount of taper in a squeeze bore is much greater).

The British made a theoretically sound and plausible attempt to work around the difficulty of drilling and rifling squeeze bores. This was a squeeze-bore muzzle attachment called the Littlejohn for the 2-pdr antitank and light-tank gun, in order to give some realistic anti-tank capability to the airborne (glider-delivered) Tetrarch light tank and various wheeled AFVs.

It squeezed the round after it had been spun to speed; the holes you can see were for pressure release. The Littlejohn was conceived by a Czech emigré, Frantisek Janacek (whose name means “little John”, literally) and was made for the 40mm Vickers S gun as well as for the 2-pdr. The ammunition featured a tungsten penetrator and aluminum carrier, must like the German squeeze-bore ammo. The US also experimented with Littlejohn type adapters and projectiles, and discovered that firing the Littlejohn projectile from the gun without the adapter produced equivalent velocity improvements without compromising the ability to fire ordinary projectiles. (In effect, this was using the lightweight projectile as in Illustration A at the top of this post, rather than a squeeze-bore as in Illustration D).

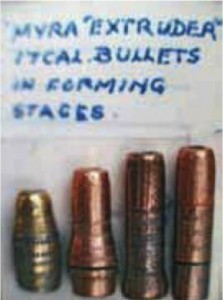

For a while, there was a squeeze bore gun that anyone could buy. Australian gunsmith Arthur Langsford, an expert in rimfire rifles, used an extended leade or forcing cone to make rimfire guns that fired an ordinary .22 LR round and produced a high-velocity .20 or .17 elongated slug. The rifling didn’t begin until after the forcing cone. They seemed to work well, but didn’t catch on, and pressure and velocity deltas between various brands and kinds of rimfire ammunition were probably larger than anything SAAMI would ever tolerate. The Myra “Extruders” Langsford made are curiosities today.

In the end, squeeze bores were a possible tank solution at one moment in time, but their performance has been overshadowed by accurate fin-stabilized discarding sabot heavy penetrators, fired (usually) from smooth-bore guns.

Next, Gain Twist, an old idea that’s making a comeback.

Sources

Department of the Navy. Naval Ordnance and Gunnery, Volume 1: Naval Ordnance .NavPers 10797-A. Retrieved from: http://www.eugeneleeslover.com/US-NAVY-BOOKS/1-NO-10797-A-NAVAL-ORDNANCE-AND-GUNNERY.html

Langsford’s Squeeze-Bore Rimfires.Is this Near-Forgotten Idea Too Good to Die? Guns Magazine, January 2011. pp. 18-19. Retrievable from: http://fmgpublications.ipaperus.com/FMGPublications/GUNS/GUNS0111/?page=18

(Others as linked. List not completed due to time limits).

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.