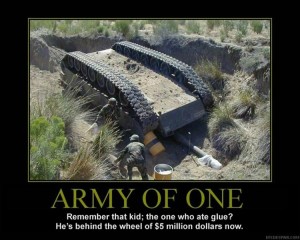

ARMY Dumb: In the Army, the Tank and Automotive Command manages small arms. SOF outsourced weapons development to the Naval Surface Warfare Center. See why?

There’s dumb, and then there’s Army Dumb.

As part of the Chief of Staff’s and Sergeant Major of the Army’s transition to a peacetime, garrison-focused, drill-square Army purged of the “indiscipline” of combat, the Army just launched a ban on aftermarket M4 magazines. This ban is reportedly targeted on the popular Magpul polymer mags, which are more reliable, more durable, and less expensive than the flimsy issue aluminum mags.

We’ve been sitting on a report on mags for a while, but in our experience one of the major problems with M16 series weapon reliability is flimsy magazines, and the dumbasses who don’t throw them away when they fail. This is compounded by the Army Dumb supply system that, in peacetime, counts mags like it was counting the gold in Fort Knox, and doles them out like they were droplets of the supply sergeant’s own precious bodily fluids. So Joe Snuffy doesn’t want to toss away the three mags of his issued six or seven that jam all the time, because he knows he’ll have to eat a lot of abuse to get them replaced.

The original AR-10 and AR-15 magazines were designed to be single use magazines — a disposable unit that would be delivered to the field preloaded, and discarded after use. But they were overbuilt for that purpose, and so the Army began treating them as durable items from the very beginning and never planned for them to be disposable, or even faced the fact that the things wear out.

Then, a combination of peculiarities in military contracting like earmarks and minority set-asides guarantees that many military magazines are made by fly-by-night contractors who pass the same old worn tooling from dissolved firm to unstable new firm, stamp and spot-weld hundreds of thousands of marginal mags, and then close their doors.

One of many models of the popular MagPul PMAG. They are not failure-proof, but seem to be superior to the issue mags.

In SF, we recognized early on that the magazine was a critical node in semi- and full-automatic M16 series weapon performance. And we substituted mags where we could. One of the first was the steel Stirling 40-round magazine. Many teams carried a Stirling mag (which were originally intended for the AR-180) in the mag-well to provide initial fire superiority in an ambush or meeting engagement. Nobody carried spares because Army pouches took almost 20 years to accommodate 30 round magazines, and never had room for anything larger. The steel mag was slightly heavier, but it was much more durable, less prone to the cracks and deformed feed lips that are par for the GI mag course.

Alternative magazines produced largely for other countries, including pioneering polymer mags from Canada (Thermold) and Israel (Orlite) weren’t sufficiently better than the issued junk. Until H&K started making an AR mag. One almost hates to mention something they did right, lest the fanboys descend in their brain-eating hordes, but the HK mag was and is the heat. You pay a slight weight price for these steel mags, but the suckers work. And they keep on working. Unlike the disposable alloy mags, the feed ramps are still in the same place after 10,000 rounds as they were before.

Now, the Russians meanwhile had reduced their soldier’s load considerably in the 1970s with composite magazines containing steel inclusions in a molded plastic shell.

TACOM LCMC MI 12-021 M4-M16 Improved Magazine and the Use of Commercial Magazines

TACOM SAFETYOFUSE(UC)

DTG: 301307Z Apr 12

Precedence: PRIORITY

DAC: General//UNCLASSIFIED//

Subject: Maintenance Information (MI) Message, TACOM Life Cycle Management Command, (TACOM LCMC) Control No. MI: 12-039, M4/M16 Improved Magazine NSN 1005-01-561-7200, Part Number: 13021312, Cage Code: 19200, Old Magazine NSN

1005-00-921-5004, Part Number: 2411362962382, Cage Code: 13629, and the use of commercial magazines. End Items: M16A2 NSN 1005-01-128-9936, M16A3 NSN 1005-01-357-5112, M16A4 NSN 1005-01-383-2872, M4 NSN 1005-01-231-0973, and M4A1 NSN 1005-01-382-0953.1. Distribution:

a. This is a Maintenance Information (MI) Message. Commanders/Directors of Army Commands (ACOM)/Army Service Component Commands (ASCC)/Direct Reporting Units (DRU), Army National Guard (ARNG), US Army Reserve (USAR)

Command, US Navy (USN), US Air Force (USAF), US Marine Corps (USMC) and other Service Commanders and Responsible Offices will retransmit this message to all subordinate Commanders/Activities.

b. This message will be available on the Safety First Web Site located on the TACOM Unique Logistics Support Applications (TULSA) portal within twenty-four hours of transmission. Access to the Safety First Web Site requires CAC Card authentication. You must first request access to the Safety First Web Site. To request access click here

https://tulsa.tacom.army.mil. For assistance, email the TULSA Helpdesk at XXX. The Safety First Web Site also has the

capability to email Safety and Maintenance messages directly to your inbox. To subscribe to the mailing list, click on, E-Mail Subscriptions, on the Navigation bar.2. Issue: TACOM has become aware of units ordering 30 rd. commercial (i.e. polymer, etc.) magazines for their M4/M16 family of weapons. The M4/M16 Army authorized magazines are the following: NSN 1005-00-561-7200 (improved magazine) and NSN 1005-00-921-5004 (older magazine; use until exhaustion).

3. User Actions: TM 9-1005-319-10, the Additional Authorized List (AAL), states that NSN 1005-00-921-5004 is authorized, as well as NSN 1005-00-561-7200. Units may use the older magazine NSN 1005-00-921-5004 with the green follower until exhausted. The improved magazine is available in stock, NSN 1005-00-561-7200, and has a tan follower. The improved magazine features an improved follower and follower spring. These new features help to reduce the risk of magazine-related stoppages. Units are only authorized to use the Army authorized magazines listed in the technical manuals. Remember; “tan-is the plan, green-start to lean, black-take it back.” Magazines with the black follower are the oldest and should be turned in to your unit supply sergeant or local supply point.

4. Unit Commanders, contact your local TACOM LCMC Logistics Assistance Representative (LAR) or your State Surface Maintenance Manager upon receipt of this message for assistance. For assistance in locating your TACOM LCMC LAR, see below.

No point including the contact info. If you’re not on a .mil you can’t get there, and if you are, you can find it.

Rereading this message, it’s pretty much a CYA move from the rice bowl guardians at TACOM. There are a number of factors in it, but the primary one is to reassert the primacy of the published Technical Manual and the nice, orderly, slow process of phasing out the most inferior black-follower mags by the more inferior green-follower mags and then the tan-follower mags on an ongoing basis.

Word is, the tan-follower mags are OK if you’re ruthless with the inevitable 10% that won’t feed, won’t hold-open, or that double-feed out of the box. Then you can get one tour out of them, but if you’re a combat unit, the reset after that tour is time to bin them.

Remember that whatever games TACOM plays with the followers, you still have mag bodies that tend to crack when fatigued, to bow in the middle, and in which the feed lips wear excessively in a few months of daily use.

Now, where TACOM has a point, is some of the aftermarket magazines out there. In our experience MagPuls (at which this was reportedly aimed, even though no brand is mentioned) are more reliable than issue mags, and about on a par with the very expensive and somewhat heavy H&K mags. They have their own failure modes, and they also have their own vulnerabilities (like ultraviolet light, to which the metal mags are fairly immune). But there are some plastic magazines, including all the cheap ones and some of the expensive ones, that are exploitative crap. Don’t even think about the el-cheapo surplus Orlites and Thermolds. There’s a reason that services are selling them off. (To some extent this is true for all surplus mags, except NIB ones).

Don’t buy a bunch of mags without torture testing a couple — test them environmentally, including in a very hot gun (if you ever need a gun really badly your gun will be on the brink of cooking off… does your mag lose its integrity at high temperatures like some thermoplastics do? That’s why Ivan used a thermosetting plastic on his). And test them with a lot of rounds before you buy them in quantity.

If that doesn’t work, stick to mags that you know someone has tested examples of to destruction.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.