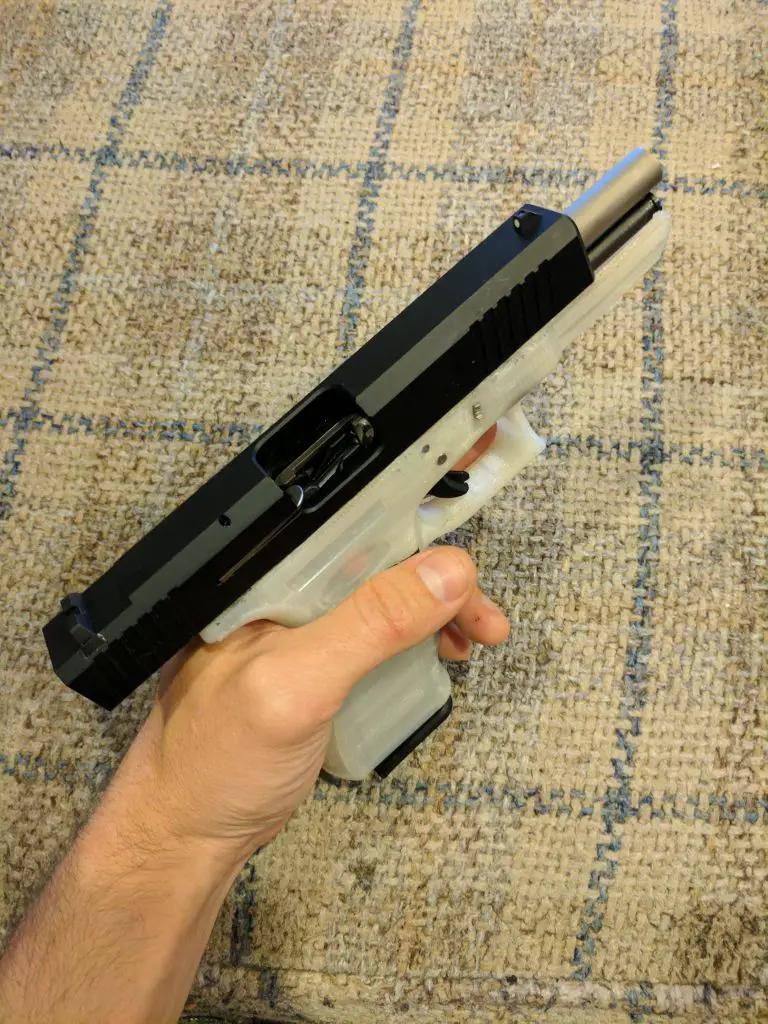

That’s sure what this looks like:

Where did it come from?

There’s a clue in the pictures, and it’s clearer if you look at this shot of the bare frame…

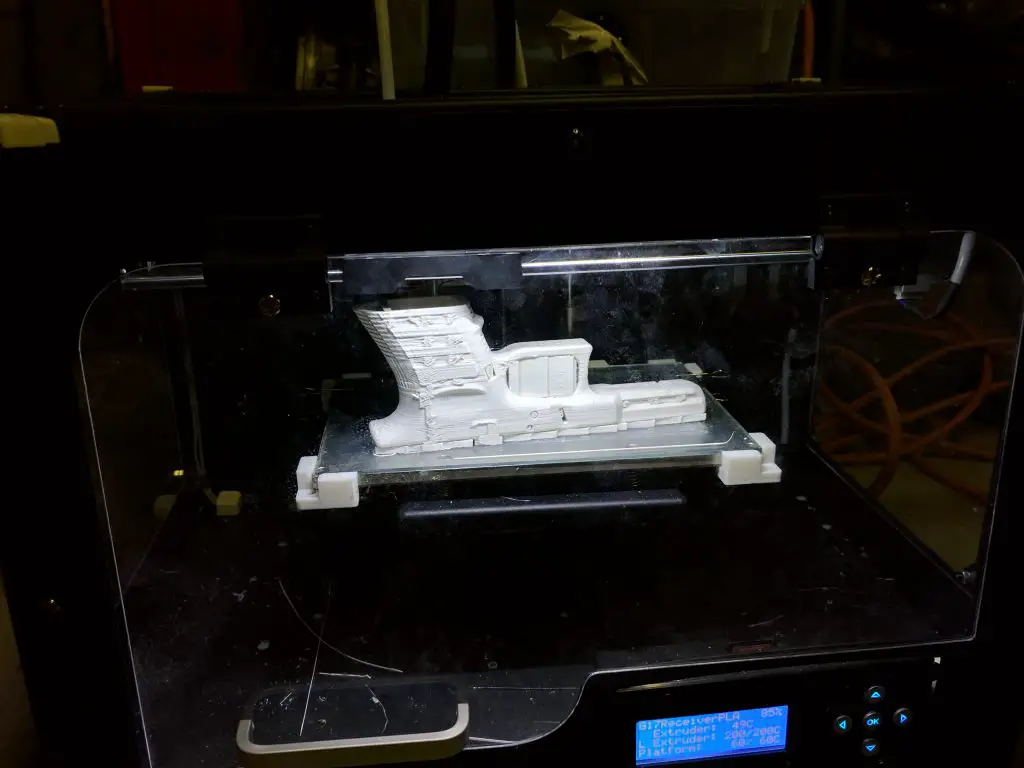

…bare frames….

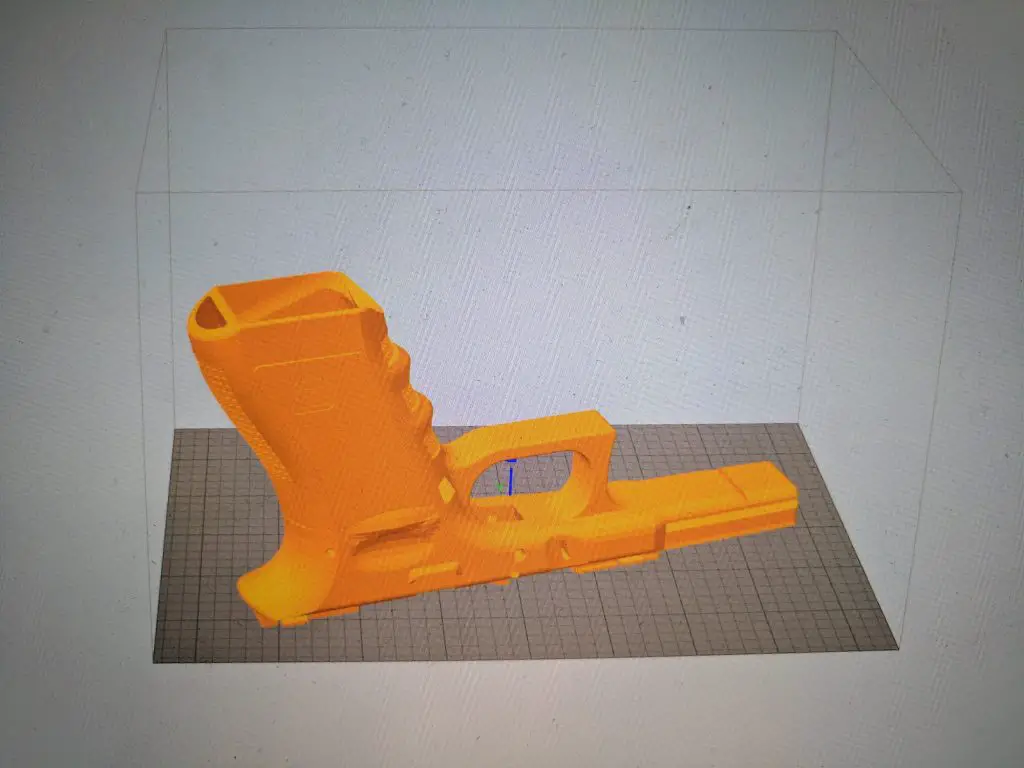

…rendering…

…and print in progress.

Yeah, it’s a 3D printed Glock. Cue the media meltdown now.

Yes, it does shoot:

Of the test fire, Matt, the maker, wrote:

First test of the frame. Fired prob 10 rounds through it. No issues found with it as of yet. …I was on a schedule and had to leave pretty quick so I ran my tests real quick to see how it looked then took off.

The frame does depend on metal rail inserts, and the designer has promised to release the .stl files… after a frame rail redesign.

Responding to skepticism about the part strength, he wrote:

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

27 thoughts on “A Translucent, .22 Glock?”

Not a Glock guy. Where’s the serial number on a Glock?

glock embeds a metal tag on the (usually) underside of the dust cover just forward of the trigger guard, and matches that number on an engraving on the barrel.

Thx. Almost a ghost gun here…

If the question is ‘where is the serial number on this homemade gun’, it doesn’t have to have one.

The law requiring serial numbers says (paraphrasing) ‘manufacturers shall place serial numbers…’, and defines ‘manufacturers’ as people building them with the intent to resell. A hobbyist making one for fun isn’t a ‘manufacturer’ under the law’s definition.

Ten years ago or so, the ATF’s FAQ book explicitly stated this – something along the lines of ‘not required, but a good idea so you get it back if stolen’. The law hasn’t changed, but a couple of years ago the FAQs started weaseling along the lines of ‘you should…’ .

I put serial numbers on mine, FWIW.

(note: I’m talking federal law here; I think CA recently added a serial number requirement)

(trivia, probably old hat to most here: serial numbers weren’t required until a few decades ago (’68??). Most manufacturers had them, but they weren’t required. I have an old SxS shotgun w/o any serial)

GCA ’68 mandated serial numbers for domestic manufacture. I believe they were required for export guns even prior to that. I own a couple of heirloom no serial number guns that predate GCA ’68.

-John M.

um, can you not use the word “trans” in your posts? it triggers me……ba ha ha ha ha ha

not being real sure, let me ask this: I’m not familiar with this nylon 910 stuff, is it more stiff then most commercially available nylon? my experience with all things nylon has led me to believe it flexes a lot more than some other materials, or to put it another way, isn’t as stiff as the various polymers. is there any chance of the nylon flexing more than polymer under recoil stresses? pretty neat if not.

Good question. Here’s Taulman’s own idiot’s guide materials chart to their current polymers/blends. As you can see they offer lots of nylons and other polymers and polymer blends. This product, Alloy 910, contains nylon and some other polymers. The length of the line above the beltline of this graph is the tensile strength, and the length below is a proxy for how flexible / ductile / durable it is. Long high line and nothing below: stiff but brittle (ordinary PLA). little above and long line below: rubbery, flexible stuff. Each has its purpose; horses for courses.

http://taulman3d.com/how-to-choose.html

***

The material he’s using is Taulman Nylon 910.

…the easiest nylon I have ever worked with. I made the dehydrator they actually have on their site and that thing is amazingly good and cheap… then I just ran the nylon on the recommended settings and it was already pretty good then I just tweaked it a bit with calibration to get my printer zeroed in and that frame was printed with no issues at all, other than some minor warp when it cooled. And as a minimum 10 hour print it had a good amount of time to mess up.***

Hmmm. Taulman 910 is good for 8100 psi, per their spec sheet. That puts it in the realm of 40mm hi-low pressure cartridges of the M79/M203 variety. Interesting….

US Army (Picatinny Arsenal) has done tests with 3D printed 40mm cases, but I don’t know what specific materials and printers they used.

The future is entertaining.

Totally off topic. Two good Swiss web sites for your Wednesday web site posts, should you be unaware of them:

http://offiziere.ch/

http://below-the-turret-ring.blogspot.com/

Highly recommend the ‘Chobham Armor’ posts of ‘Below the Turret Ring’:

http://below-the-turret-ring.blogspot.de/2016/03/chobham-armor-facts-and-fiction-1.html

http://below-the-turret-ring.blogspot.com/2017/01/early-m1-abrams-composite-armor.html

These are really good. The tank guy updates seldom but his material is all interesting stuff.

While not a big threat due to the so far limited number of 3D printers being used by general public do imagine would give the poly80 folks a reason to drop the price on their new poly glock model.The originals from poly80 down in the 60 buck range,the demand on barrel/slides have at moment made a expensive option still believe some enterprising folks will be putting out options that will make this a more price friendly endeavor.

Speaking of poly80,believe some blogger has one floating among the detritus of said projects,ever going to see the light of day,am sure thing interested!

Yeah, there’s a couple of them, and they’re bacburnered due to the evaporation of Glock parts. Poly80 has a G19 size kit now, too.

Yep,and the new compacts have a real rear metal rail insert along with the front insert/lock block.That said,back in the 140 range though feel will soon come down in price,someone could make a good amount of money they put out quality slides/barrels at a competitive price.

what a time to be alive

Does anyone have a nearest-thousands estimate on the cost of the rig he uses to print these suckers?

-John M.

I didn’t see a printer model mentioned in the reddit threads, but I was interested enough to spend an hour googling about nylon capable printers. If a 6x6x6 envelope is sufficient there were ones as cheap as $1200. 12x12x12 was up to $2500. One that had two heads, so you could include fiber reinforcement as you printed was $7000 or so.

The consensus was that nylon was fussier than the usual weaker plastics.

Anyway, thanks, HN, for the post. I’ve mostly ignored 3D printing because I didn’t have any uses for PLA. Now I have to start paying attention!

Thanks. That’s small enough money that if someone wanted to bang out a small set of Glock-offs, he could get within spitting distance of ROI pretty quickly.

-John M.

You can print nylon on a higher-end open-source or common commercial printer, you need a heated bed and an enclosure helps. Keep the nylon dry (hard as the stuff sucks up moisture), the hot-end clean and hot, and the bed heated. Pretty sure that’s what Matt did.

3D printer: $3000

Nylon material: $100

Online Glock file: Free

Untraceable handguns not on anyone’s list: Priceless

Cue ChuckU Schumer hyperventilating to get BATFE to put 3D printers on both the NFA list, and the State Dept. list of ITAR items, if not banned as WMDs outright, in 3, 2,…

And hey, if they can make a frame that’s about a second away from being glow-in-the-dark, why not just mold normal sights with the GITD material embedded, rather than added afterwards?

Just wondering…

“Make Chuckie Schumer Cry Again.”

-John M.

The ATF guys had a cerebral hemorrhage trying to decide what about a 3D printed Glock is a gun. When does it become a gun? Is the file the gun? Is it when the print is finished? Probably.

It was worse with the home polymer casting kits. Is it the mold, or the polymer itself? The polymer is a liquid with no form until it’s poured, but the mold is the “negative shape” of the gun and incapable of doing anything.

Sig, in govt, speak truth a lie/day is night ect. real easy to see negative is the positive/liquid is solid ect.that said,barn door already open ect.sorry chukie.

Awesome! With the continual UN agenda’s to dis-arm the world, I am hoping you people continue to keep expanding your research and making downloadable plans! What would be the cost of a 3D Printer that would be available, that can replicate the handguns you are designing here! I believe the shit is about to hit the fan in the world big time soon, and it would be awesome to be able to make and stockpile these guns, for self defense! Keep up the good work!