Consider this graphic. It is a somewhat crude reproduction of one in the Rheinmetall weapons design handbook. Secretary of State John F. Kerry, who is unlucky at bicycles bur uncannily lucky with heiresses, thinks that we all should be criminals for discussing this online, so let’s all get our crime on and return to a subject we’ve discussed before, heat management in automatic firearms.

The original of this graphic is a rather dull monochrome one in the style of the rather dull, unless you are the sort of gun geek that Secretary Kerry dreams of decanting into durance vile, Rheinmetall Handbook. Our copy is the German language version, because we read po-nyemetskiy, and Amazon.com wants $300-400 for an English copy, when there is one to be had, but Amazon.de has copies of this out of print classic for about €100. (Which is going to be lunch money if they keep letting Greece set continental fiscal policy). It took us several iterations to get the slopes about right, and we got the round-count wrong: it’s supposed to be two neat Teutonic bursts of 10, and we have a rather limited and non-Aryan 8 and 9, but with that difference noted, this graphic is close enough to discuss the phenomena at issue. Here’s what Rheinmetall says about this graphic:

The barrel of an automatic weapon is, as a consequence of the normally high rate of fire, subject to extraordinary temperature demands.

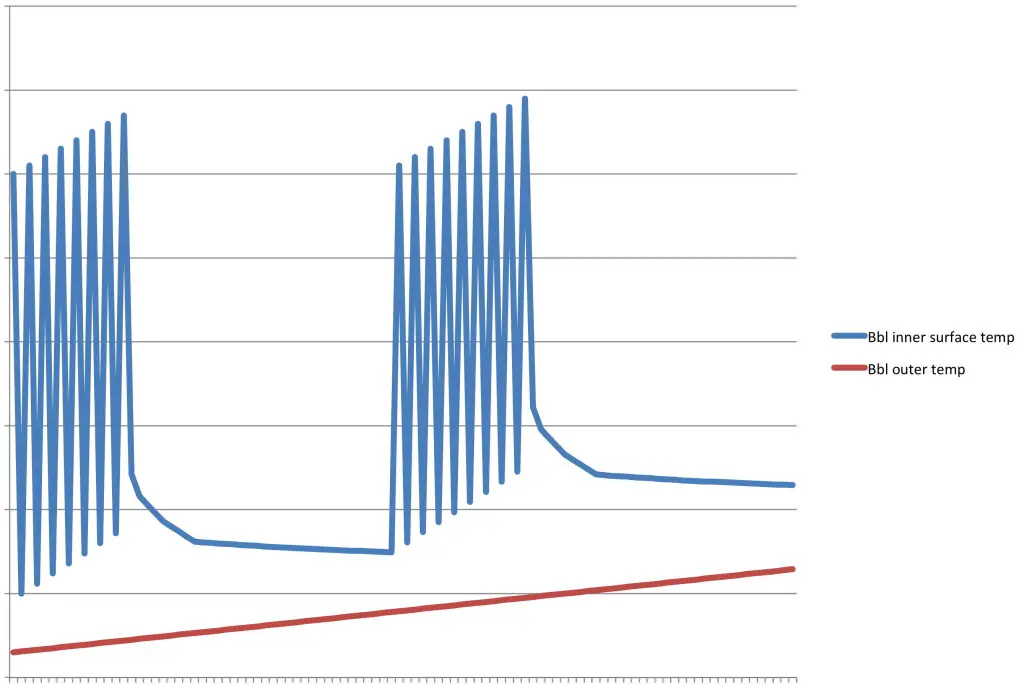

[This illustration] shows the approximate course of temperature of the inner- and outer wall of an MG barrel in two bursts of fire of 10 shots each with a pause lying in between. Feel long, or many short, bursts of fire can drive the temperature of the inner wall so high, that it has a significant influence on the material toughness and therefore on its use and employment.

In this, the cadence of fire, the number of shots in a burst, the pauses, the lengths of the pauses, and the number of bursts of fire fired rapidly one after the other, in conjunction with the thermal resistance of the barrel material and the strength of the barrel walls all play a role.

Comparable barrel-life shot counts can therefore be reached with the same firing rhythm. Often the “French anti-aircraft rhythm” is used: this is 144 shots in 12 bursts of 12 shots each, with a 2-second pause after each burst and a 20 second pause after every four [bursts]. With MG barrels, a firing rhythm of 250 rounds in numerous bursts is often used.

For testing automatic weapons and their ammunition, Rheinmetall has developed an electronic Rate and Rhythm Control Apparatus, which is described below in section 7.7 [of this book].

Measures for increasing the life expectancy of barrels include:

- Heat-resistant materials;

- Chroming or Nitriding the interior wall;

- Progressive twist and rifling profile in conjunction with barrel caliber tightening.

Less effective are cooling fins and water cooling.

Barrels for MGs and machine cannon must be rapidly interchangeable.

Now, this graphic is limited in its utility because in its original version, it comes without any numbers attached (accordingly, we have eliminated from the version we show you, the numbers we used for temperature (ºC; as you might expect the Handbook exclusively uses SI units) and seconds to approximate the original. But we can draw some conclusions based on the shape and gradient of the two lines.

Our take-away is that the key point is that the baseline is higher after each burst, and that the internal temps go higher in each successive round of each successive burst. What does not show on this line is the temperature where the barrel fails. As we have seen in the M4 experiments wherein a carbine was tested to destruction, this happens at a fairly predictable and repeatable, ergo constant from an engineering point of view, temperature. As Rheinmetall points out, several roads will get you to that temperature sooner or later.

Maybe he didn’t know this, but thus is why your sergeant whacked you upside the hemmet and told you to fire shorter bursts.

Looking at the Rheinmetall data, it seems that for their test weapon, whatever it was (MG3?), the barrel recovers its temperature rather speedily after the passage of each bullet momentarily superheats it. We would attribute this to the limited ability of a small projectile’s friction to heat the much greater mass of the barrel — this is also why the internal and external temps diverge so widely. But note that the internal temp continues to ride steadily as long as a steady sequence of pause and fire is applied, and at each pause the internal and external barrel temps have diverged more widely.

The implication is that an automatic weapons barrel is going to be heated to its limits at some point, moreover, at some predictable point, in any continuous fire regime, and while some of the magic designers have used over the last century, like chrome plating and stellite liners, can give you some more rate of fire on the margins, only changing out the barrel (not usually possible in a light automatic carbine) or otherwise giving the barrel a chance to rest and recover from high temps will prevent failure.

Thus endeth the lesson. Apart from further education which may come in the comments.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

10 thoughts on “A Tale of Two Temperatures”

Given that you have an international readership, maybe that makes us all international criminals? Cool.

It would be interesting to see something similar for suppressors.

To the best of my knowledge, any such data is proprietary and unpublished. Phil Dater may have done something like that.

Of course, changing temps in the can will change pressures, and the whole fluid dynamics of the thing changes with it. In a suppressor, it’s more about temp propagation in fluids (air/combustion gases) than in solids (barrel steel) .

Had a Korean War vet tell me that his M-2 during a mass wave attack he could see the bullet travel in the barrel as he touched each round off. He said his barrel was red hot and the bullet was a different color, or at least you could something flash down the length of the barrel. Could the cooler bullets have been a heat sink in that situation?

The inner barrel surface is cooled through conduction to the outer surface, any gas flow through that long pipe is largely irrelevant to the overall cooling function. But, if I am going to be firing long strings through a bolt action rifle, I leave the bolt open for as long as I can between shots to maximize what little air flow it can get.

The outer surface is cooled by convection and radiation. This is why adding fins sort of helps but not much, convection is limited by the rate of gas exchange and interaction with the surface area. Simply creating more surface area doesn’t make the gas exchange any faster. As far as increasing the radiative properties of barrel steel, good luck, ordnance phosphate finishes are as close to a “black body” as any that I can imagine.

The engineering ideal would be an ultra hard bore surrounded by an ultra conductive and radiative material to more rapidly pull heat away from the bore. Armalite experimented with aluminum based barrels back in the 50s with horrible results, and more recently various “carbon fiber wrapped barrels” have come on the market promising that even mag dump after mag dump the barrel will still be safe to touch with bare skin (without saying that excellent insulating properties would also allow that to happen).

Suffice to say, the materials that are good at cooling down are generally not the materials you want to build rifle barrels out of. But if I had to pick the best option on the market today, it would be a Lothar Walther Ultralight bimetal (steel and aluminum) barrels. Even if the heat shedding capacity isn’t amazingly better, it’s still an improvement in heat management and weight reduction, sort of the holy grail of military arms.

I’ve been wondering about titanium or some kind or layered thing with a cobalt alloy (Inconel, Stellite) inside Ti alloy. Or maybe carbon-epoxy or carbon-carbon. The gun world has finally followed Stoner and Sullivan down the path of aerospace manufacturing circa 1950, we need to wake up to some of the post-Jet Age developments. Says the guy who’s riveting sheets of aluminum for a plane that’s a close equiv of a 1939 Ercoupe.

It was a surprise to read that water-cooling wasn’t so hot according to Rheinmetall. I wonder what assumptions and conclusions come along with that, bearing in mind the reputation of Vickers MMG’s et al for sustained fire. That reputation was gained in siege warfare on the Western Front in the Great War, but endured far beyond it, and I’m not convinced it was without merit, in that application; static & linear positions and a target rich environment. I suppose one could come up with an add-on water jacket to complement chrome or stellite bores and quick change barrels without too much trouble. It wouldn’t prevent ultimate barrel failure, but perhaps delay it long enough. Long enough to make the trouble worthwhile.

I was surprised by the low rating of water cooling, too. But then Rheinmetall was judging on accuracy, not the ability to sustain fire near-indefinitely. Then again, I suspect MG barrels of the air-cooled variety might be much thicker than the barrels for water-cooled guns, so water cooling measures would be less effective due to the mass. A pencil barrel will cool off much faster than a heavy barrel, but it will take less rounds before POI/POA shift occurs.

Hmm, I wonder if someone tried brine instead of water, for even better cooling.

David Drake wrote HAMMERS SLAMMERS, a sci fi merc group that conducted business in the future. He wrote about an interesting concept where the automatic weapons would “squirt” coolant into the barrel after each shot. The coolant came from the cartridge that was fired.

@AM: I have to argue with you about cooling fins. We don’t put all those fins on heatsinks for electronic power devices just for looks – they do help with convective heat transfer, which can remove heat quite efficiently if it reaches the fins. There are two points of diminishing returns with finned heatsinks. The first is getting the heat out to the base of the fins; I can buy a 50 watt heatsink, but it won’t do much good if the device I’m trying to cool can only transfer 5W from the core to the heatsink before the core overheats. The second is heat transfer along the fins; it’s quite possible to have the baseplate hot enough to boil water while the tips of the fins are barely warm. The outer part of those fins is just wasted weight.

Judging by Hognose’s graph, cooling a gun barrel is dominated by the first problem, getting the heat from the inner surface to the outer surface. Keep up that firing pattern and the inner surface will have softened and eroded out past the last trace of rifling before the outside is hot enough for it to matter how it’s cooled. If the spacing between bursts was several times as long, then cooling fins or a water jacket would help, but whenever combat gets intense, you will reach a point where only a barrel change will dump the heat fast enough. (That’s assuming only one or two barrels; a modern gatling is different, not because it’s impossible to overheat six barrels, but because no one carries that much ammunition.)

Titanium is a poor material for military guns – it’s thermal conductivity is 1/4 that of steel. Heat will stay on the inside until it becomes too hot even for titanium to hold up. The one exception would be if the barrel or the whole gun was considered expendable, so more rounds fired at a rapid rate before overheating would outweigh the much longer cool-down time. This might actually match what was alleged to be Soviet doctrine – that a front-line unit was not only expendable, but it was considered expended in the first heavy combat. Rather than sending more ammo, etc., the Soviets lined up replacement units behind the ones in combat. Any survivors who made it back after expending all their ammo would be re-equipped and re-organized into new units. However, the _cost_ of titanium certainly didn’t fit Soviet resources; by the time a country can afford that, they’ll probably be like the 21st Century US Army, doing everything possible to keep its soldiers alive, beginning with equipment that just keeps on working under all conditions, no matter what that costs. (The problem is, that’s not possible in a modern firearm; there simply is no way to keep the gun from overheating other than unduly restricting the rate of fire or the supply of ammo. Hence replacement barrels for machine guns, but machine guns don’t need to be sighted in. Is there anything that could be done for rifles?)

A thin steel barrel with an aluminum jacket: This is the best idea I’ve heard, since Al has three times the thermal conductivity of iron, but you’ve got to deal with all the problems of dissimilar metals in contact. Coatings might prevent galvanic corrosion, and one thing the Army does do well is keep things “painted”. Aluminum expands about three times as much with temperature as iron; alloys can modify this behavior somewhat, but I think with reasonably effective alloys the jacket will still be apt to expand more than the liner. Perhaps this would be countered by the lower temperatures in the jacket, but I suspect there would be a period during cool-down after the battle when dropping the weapon would tend to separate the liner and jacket.

Finally, there’s an inherent conflict between thin barrels for better cooling, and thick barrels so they don’t bend when they get hot. Perhaps there is a middle ground by machining lengthwise flutes in the barrel – most of the section is only thick enough to meet the bursting strength requirements, but there are longitudinal ribs to stiffen the barrel.