We haven’t celebrated it in recent years, just because we get buried by events, but 19 November, this and every year, is National Ammo Day, sometimes called National Buy Ammo Day. Your mission, should you choose to accept it, is to buy 100 rounds of ammo. Photos in the comments are a plus!

We haven’t celebrated it in recent years, just because we get buried by events, but 19 November, this and every year, is National Ammo Day, sometimes called National Buy Ammo Day. Your mission, should you choose to accept it, is to buy 100 rounds of ammo. Photos in the comments are a plus!

The minimalist National Ammo Day website explains the event as follows:

November 19 is National Ammo Day.

It is a nationwide BUYcott of ammunition. You buy ammunition. 100 Rounds a person.

The goal of National Ammo Day is to empty the ammunition from the shelves of your local gun store, sporting goods, or hardware store and put that ammunition in the hands of law-abiding citizens. Make your support of the Second Amendment known—by voting with your dollars!

There are an estimated 75 MILLION gun owners in the United States of America. If each gun owner or Second Amendment supporter buys 100 rounds of ammunition, that’s 7.5 BILLION rounds in the hands of law-abiding citizens!

We think he’s seriously lowballing the number of gun owners here. But getting them all to buy ammo on one day — well, it’s a fond hope, but We Will Do Our Part. And maybe pick up some of all y’all’s slack.

The gun/ammunition manufacturers have been taking the brunt of all the frivolous lawsuits, trying to put these folks out of business. Well, not if we can help it! And we CAN help it by buying ammunition on November 19!

National Ammo Day Week

National Ammo Day is on November 19 and that is the day when you mark your calendar. In the text above you may have noticed that we used the phrase “Ammo Day Week.” That is because it is sometimes impossible for someone to get to the store on that specific day to buy ammunition, so we broaden the time when someone may make a purchase, but still have it counttowards an Ammo Day purchase.

So what does count? If you buy ammunition on November 18 or November 20 (the day before or after) does that count? What about November 1 or December 1? These are all questions that have been asked.

Here’s the rule regarding Ammo Day purchases and whether they count: The Saturday to Saturday, constituting a full week. For example: If November 19 fell on a Tuesday, it would be the Saturday before (the 16th), through the Saturday after (the 23rd). November 19 will generally fall somewhere in the middle of that week, unless the 19th is on a Saturday (then, and only then, Ammo Day Week begins on the 19th).

Mirabile dictu, the stars align in 2016 so that National Ammo Day Week begins on Saturday, 19 November. Who knows what ammo lurks in the shops and stores of the nation, like a lost puppy seeking its forever home?

Please, but the ammo today (er, tomorrow) so that we won’t have to have television appeals with sad-looking 7.62 Tokarev rounds, and a voice-over by Sally Struthers. That would be a crime against all humanity and decency.

Note also that National Ammo Day is the Feast of St. Crispin (doesn’t appear to be the same one celebrated by Anglicans on 25 October), and a High Holy Day of the Ventilarian Faith.

British Ammo Improvements

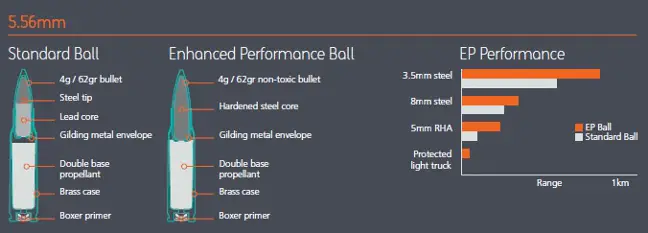

It isn’t just the USA that’s turned away from the 1970s-vintage SS109 round (which is what our 62-grain M855 was, essentially) in pursuit of more accurate ammunition with improved terminal ballistics. The UK has done so, also, although they’ve gone in a different direction from the US.

BAE Radway Green, the Britsh military ammo monopoly contractor, has also improved the venerable 7.62mm round. The British tech ‘zine The Register visited Radway Green and has a rundown on the new ammo — heavy on The Reg’s patented juvie snark, but well-stuffed with technical details.

What’s changed? … It’s all down to penetration – or punching the same depth of hole in ever-better-protected targets.

While RG’s existing products, the 7.62mm L44A1 and the 5.56mm L17A2 cartridges, did that more than well enough when they were originally specified by the Ministry of Defence, modern battlefield technology and techniques mean the military are looking for something with a bit more oompf to fire down their rifles and machine guns.

RG has swapped all-lead bullets for steel in pursuit of better penetration against hard targets – though there’s a lot more to it below the surface.

The two new designs of cartridge, known as the Enhanced Performance (EP) round in 5.56mm and the High Performance (HP) round in 7.62mm, feature new – and, in the HP’s case, heavier – bullets. In addition, the HP round switches from single-base propellant powder to double-base, to give the heavier bullet the same flight characteristics as the old one. The EP also discards the age-old NATO SS109 bullet design, which incorporates a steel tip in front of a lead core, for an all-steel bullet, cased in the same gilding metal jacket as before. Its profile is similar, though.

The genesis for this seems to be the same as that for the US Army and USMC’s newer rounds — technology made better ammo possible. Unlike the Americans, though, the British Army didn’t have to sell the ammo as a “green” boondoggle to social-engineering obsessed Ministry of Defence.

Simon Parker, a project manager at BAE Systems Radway Green, spoke to The Register about the new rounds and the decisions behind the changes in their makeup.

“We wanted to see if we could improve performance against hardened targets. Having a solid hardened steel core improves performance above that of the steel tipped round,” he said. The new 5.56mm round, which will be known as the L31A1 in British service, retains a bullet weight of 62 grains (4g), meaning its ballistic performance will be very similar – an important similarity for soldiers firing it down their SA80 rifles.

For the 7.62mm round, known as the L59A1 in British service, the biggest change is to the weight of the bullet, from 144 grains (9.3g) to 155gr (10g). This increased maximum weight allows the new bullet to incorporate a steel tip, similar to the 5.56mm NATO SS109 design, giving it more mass with which to punch through a light target. Graphs from BAE claim that the HP bullet can penetrate an 8mm steel sheet out to about 400m, whereas its predecessor could only manage it at half that distance.

“We have a standard ball round which is 144gr and a sniper round which is 155gr. The sniper round is manufactured under tighter tolerances and conditions. The 7.62mm High Performance round is not quite the same as the sniper [round] but it’s considerably improved over the standard 144gr bullet,” said Parker.

The propellant in the new 7.62mm round is the same as the 155gr L42A3 sniper rifle round, which is continuing in production. It is a double base propellant – so why the change from single base?

“It’s merely because it’s heavier,” said Parker. “Moving from the 144gr to the 155gr means you need a bit more energy in the propellant. We already use the double base propellant in the sniper round so it’s the same propellant as is used in the sniper round.”

It’s interesting to note that the 5.56 round is Boxer primed, and the 7.62 Berdan primed.

Yeah, but how does it work in the real world? Does it pop hadjis?

“The old Green Spot was just the best lot of ammunition that we manufactured, taken off and marked as Green Spot… but 7.62mm HP would outperform Green Spot,” said Parker.

“We’ve not designed it for a sniper rifle application – though the Special Forces use it as such and that’s fine – but it has been adopted in the sharpshooter rifle [the Army’s L129A1]. It was purchased as a UOR and subsequently adopted. We recommended the use of 7.62mm HP and the user really loves it. But it was originally designed, truth be told, for improved target performance through any weapon system. We made it and designed it so it can be functioned through the GPMG and it’s also being used by the Royal Navy in their Miniguns for defence of ships.”

Do Read The Whole Thing™. The section on the environmental testing that the ammunition endured on its way to acceptance — and that samples must continue to endure — is quite illuminating all on its own.

For more information, BAE Systems has a page on the new ammo, with a rather cool video we were unable to figure out how to embed — so go there to watch it. The ammo has been in production for the UK MOD since 2015, but is now being offered to other military forces.

Boxer and Berdan in Under 1000 Words

In the early days of fixed ammunition, 1840 to 1870 or so, the best way of doing things was far from being settled or self-evident. Many designers worldwide had the same idea: concentrate the primer, powder, and projectile in a single self-contained cartridge. A cartridge could be made of many materials, but whatever it was made of, it offered speedier loading, a simpler manual of arms than any externally-primed system, more ignition reliability, more consistency from shot-to-shot, and even a small degree of waterproofing. With the advantages so clearly evident, next task was to make the cartridge, and a weapon to fire it. In Europe, pin- and needle-fire arms were up first; in America, rim-fire guns were first.

Pinfire was invented by Casimir Lefaucheux in the late 1820s and 1830s, as an improvement of Prélat & Pauly’s needle-fire design of the early 1800s. Johann von Dreyse, who had worked for Pauly, developed a version of the needle gun that became the Prussian standard, the Dreyse Needle Gun, and the French countered with a needle-gun of their own, the Chassepot. Russia briefly adopted the Karl. All these pinfire or needle-fire weapons would be replaced by centerfire cartridge firearms in good time.

Meanwhile, rimfire, originally developed for the indoor guns of Flobert, was adapted to .22 caliber in the .22 short Smith & Wesson Model 1 revolver. Early rimfire cartridges all used black powder exclusively, but “rimfire” then was not always, as it is now, a synonym for “smallbore.” Larger cartridges than the .22, like the .44 rimfire used in the original Henry rifle, and the .56-56 Spencer, evolved (and weapons evolved to use them). By the end of the Civil War, quite a few Union cavalrymen were armed with breechloading rimfire repeaters.

Centerfire offered advantages over rimfire. It uses less priming mixture, and that, and the central location of the centerfire primer, makes rounds more stable in handling, and also ensures the primer can ignite the propellant more evenly.

The first centerfire cartridges were made much like rimfire cartridges, drawn from thin cups of copper into a thin-sheet construction of uniform thickness, or thinness really, like the familiar .22 rimfire. An internal cup lined the so-called “balloon head” cartridge and had a small cup in it with a place for priming compound, an impact-sensitive fulminate or styphnate of a reactive metal.

For example, the Martin and later Benet cartridges used in the early center-fire Allin conversions of muzzle-loading Springfield rifle-muskets were this type; even the casings recovered at the Little Big Horn were like this. These cartridges were, like rimfires, not practically reloadable. While today, reloading is largely practiced by hobbyists, in the middle of the 19th Century, it was considered beneficial for soldiers and frontiersmen in the remote extents of the American West and the outposts of the British Empire to be able to reload spent casings.

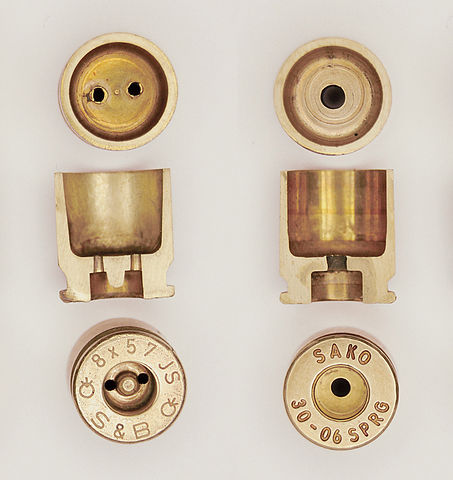

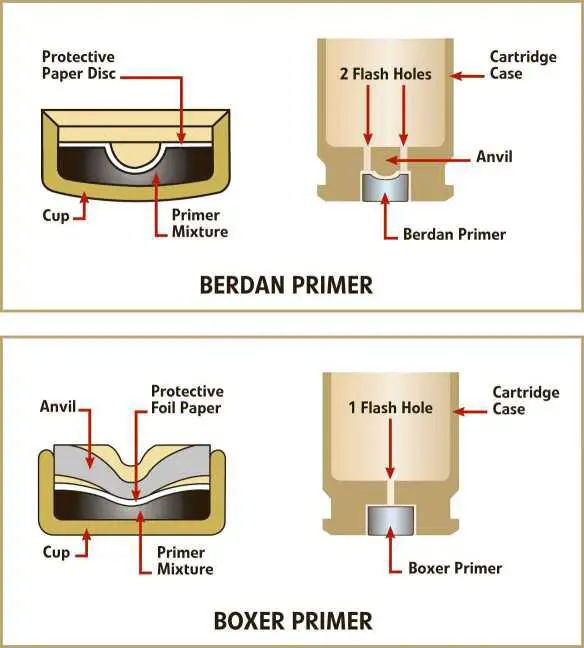

There are two types of priming systems for centerfire cartrifge in use today. Both date back 150 years, to 1866, and in all that time, neither has overcome the other. That is because each one offers specific advantages — the system you choose depends entirely on which advantages you give more weight to.

Each system was developed by a man who had earned the rank of Colonel in his national Army: Hiram Berdan of the United States and Edward M. Boxer of Great Britain. Both were Ordnance officers, although Berdan did distinguish himself in command of a Sharpshooters (skirmishers or light infantry) unit in the Civil War. Boxer was superintendent of the laboratory at Woolwich Arsenal. (Boxer’s family produced many distinguished Army and Navy officers).

Originally, Berdan’s system used a drawn brass case with a heavy, solid head, a primer cup with an integral anvil, and two flash holes in the primer cup set 180º apart. Boxer invented a self-contained primer with its own anvil, and originally intended it to be used in a thin-sheet copper case with a single flash hole on the centerline. The strength advantages of the Berdan case were so evident that Boxer’s system was quickly adapted to the stronger heavy-base drawn case. Berdan had patented his integral-anvil primer pocket, but not the drawn-brass heavy-head cartridge design.

Accordingly, long before the turn of the century, the only remaining difference was the primer and primer pocket design.

The principal advantage of Boxer’s primers is that they lend themselves to reloading. Berdan’s casings were intended to be disposable. Boxer cases are easily deprimed with a needle that poked through the single larger flash hole. Berdan primers are best deprimed hydraulically, by forcing an incompressible fluid into the case. Boxer primers are also a little more robust and easier to handle than Berdan primers. At an industrial level, it may be cheaper to make Berdan primed ammunition. While making a Berdan case is a little more complicated and costly than making a Boxer case, the complex multipart Boxer primer is an assembly of tiny parts that must be precision manufactured to be reliable. The primer complexity more than offsets the case simplicity.

The Boxer system took off in the United States, where cartridge reloading was very common among individuals on the frontier, and where much more ammunition is produced for the civilian market than for the armed forces, and in many more varieties. In Europe, where firearms were more likely to be produced by state arsenals for state actors, in few standardized calibers, the economies of scale justified Berdan priming.

In the US, surplus ammunition with Berdan primers is likely to be corrosively primed, but that is correlation without causation. Either kind of primer can contain a corrosive or a less-corrosive (We don’t think any of them is truly non corrosive) impact-sensitive priming compound. The older the ammo, the more certainty that its primer will leave highly corrosive salts in the bore and action of a firearm, and that’s true of Boxer and Berdan primed ammo alike.

Orbital ATK Gets a Big Ammo Order

This week brought forth two releases from Orbital ATK, the defense giant that spun off its commercial ammo business as Vista Outdoors two years ago to focus entirely on the government market.

This week brought forth two releases from Orbital ATK, the defense giant that spun off its commercial ammo business as Vista Outdoors two years ago to focus entirely on the government market.

The first release, the one we’re interested in, is about ammo contracts, and it’s good news for OA, if not unexpected. The company will be making over $200 million worth of small arms ammunition for the US Army — enough, perhaps, to relieve shortages of training ammunition, and even enough to get all the combat service support folks qualified without resort to the M1 pencil. We’ll elaborate on the contract in a bit.

NYSE: OA on 5 May (sometimes there’s a benefit in a post not being on time at 1100, isn’t there?)

The second one was the quarterly earning call with financial analysts. That one was more of a mixed result; immediately after the 9AM call, OA stock took a header, but it rebounded in the afternoon, and after what looks like a little profit-taking, was actually up by day’s end.

These conference calls are a relative proposition: how well did the company make its number, not absolutely, but in the light of the Wall Street analysts’ average expectations? The good in the call came from the company meeting earnings per share (profits) estimates exactly at $1.31 per share. But even though Orbital ATK revenues were up nearly 10% over last year to $1.06 billion, the analysts had been looking for almost $100 million more, and OA missed that $1.14B target. But that wasn’t all the bad, the CEO dropped a bad-news bit that suggests that the company hasn’t met “synergy targets,” from the ATK-Orbital merger, and says he’s still looking for $30 million a year in cost savings — not good news if you’re an employee there, because that’s a target on your back.

OA is a complex company that does everything from launch a few colossally expensive satellites every year, to manufacturing billions of 5.56 rounds for the US Armed Forces and America’s Foreign Military Sales customers.

The ammo contract press release says:

Orbital ATK, Inc. (OA)… announced today that it has received orders totaling $210 million to produce small caliber ammunition for the U.S. Army. Orders were placed for .50 caliber, 5.56mm and 7.62mm ammunition under Orbital ATK’s supply contract to produce a variety of small caliber ammunition for the U.S. government at the Lake City Army Ammunition Plant (Lake City) in Independence, Missouri.

“This latest order continues a long history of supplying only the best ammunition to our warfighters,” said Kent Holiday, Vice President and General Manager of Orbital ATK’s Small Caliber Systems division of the Defense Systems Group. “Every round is produced with the highest quality because we know that those defending freedom depend upon the good work of our employees.”

Orbital ATK has operated Lake City for the U.S. Army since 2000, during which approximately 15 billion rounds of small caliber ammunition has been produced to support U.S. and allied warfighters around the globe. During the past several months, Orbital ATK and the U.S. Army have been making upgrades and investing in state-of-the-art, high-volume technology to enhance the efficiency and cost-effectiveness of the facility.

As the press release suggests, the Army owns the plant, but Orbital ATK (and its predecessor, ATK) operate the plant under contract to the Army.

One annoying detail: the contract contains a 2005-vintage clause[.pdf] that requires Orbital ATK to destroy any leftover ammunition, parts, components rather than sell them to the public.

There’s a rumor going around that the new contracts are specifying steel rather than brass cases. That seems unlikely; from what I’ve seen of these contracts, they’re just refills of the same old ammo.

Steel cases promote action and barrel wear, which has been demonstrated in tests. We doubt that it is due to a single mechanism, but we expect it was principally because of poor obturation. The guy that invents something that gives better obturation than good old brass is going to create a revolution in ammunition — assuming that it has other properties that beat the old golden stuff.

How Stripper Clips were Made in 1916

When the world was in arms, and the arms were bolt-action, the essence of “rapid-fire” reloading was the stripper clip. While a few nations (notably the Habsburg Empire) use Mannlicher en-bloc clips, most of them used Mauser-type strippers. After encountering the superior Mauser rifle in the Spanish-American War, the US took steps towards adopting a Mauser-derived rifle (which would ultimately yield the 1903 Springfield and its .30 caliber ammunition). As an interim measure, America experimented with a stripper-feed option for the .30 service rifle, the .30-40 Krag-Jorgenson. Only 100 Krag rifles and 100 carbines were made with the so-called Parkhurst device in 1899; this one sold at Rock Island Auctions in 2010.

Hmm. Here’s a side view:

The Parkhurst Device is a forgotten footnote to firearms history, but the procedures developed to manufacture and load stripper clips had arrived in the arsenals just in time for the adoption of a stripper-loaded firearm, the M1903 Springfield rifle.

For a simple assembly of metal, the manufacture of the stripper was fairly complicated:

Let’s see what a period (1916) book had to say about manufacturing these clips.

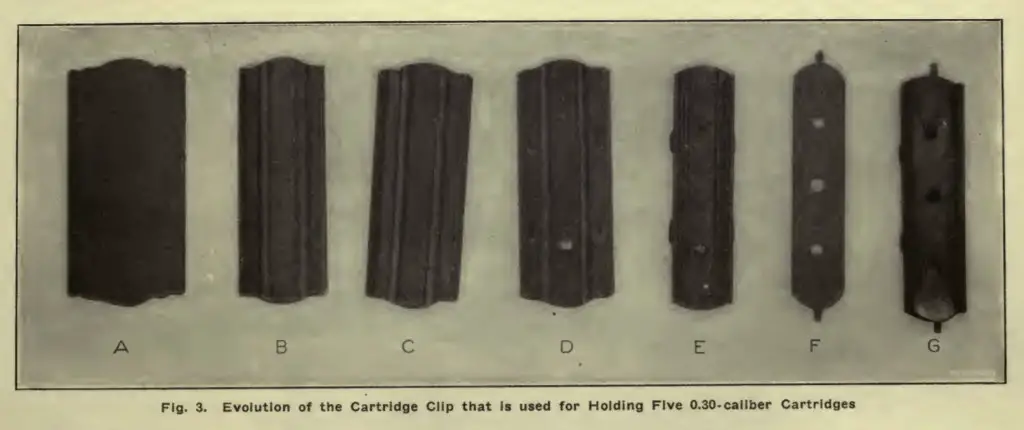

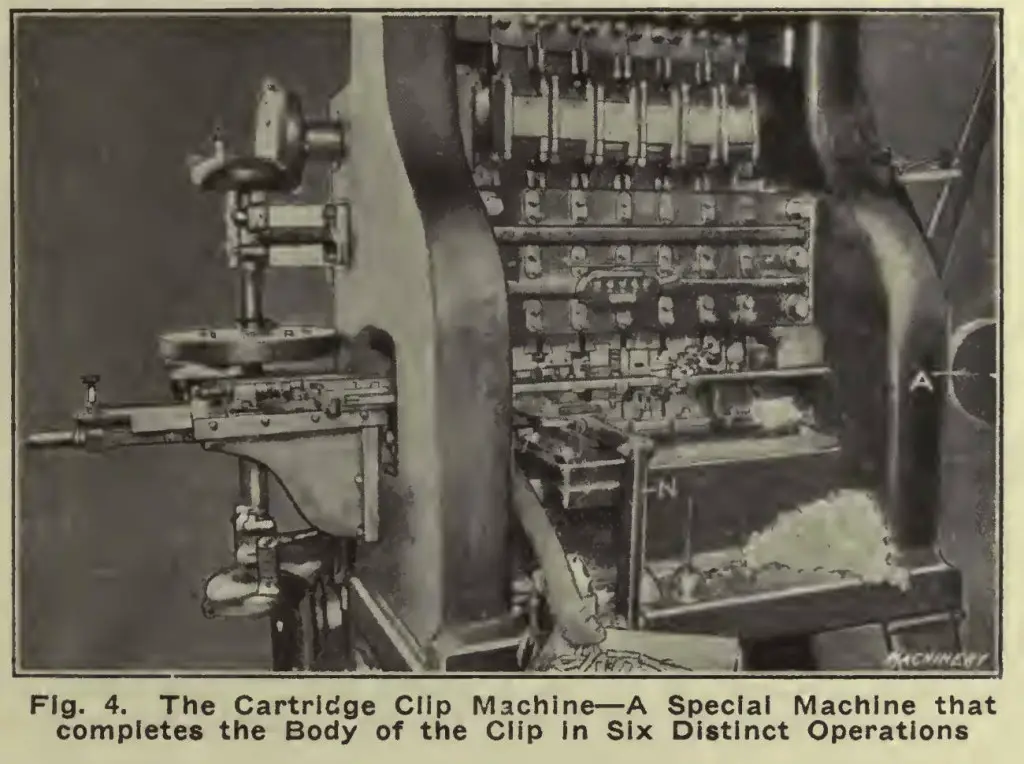

Making Cartridge Clips. —The device for quickly inserting cartridges in the magazine of a 0.30-caliber rifle consists of a clip * which holds five cartridges sufficiently tight to prevent them from falling out. As soon as the clip is placed over the breech and the top cartridge pressed, they are ejected and pass into the magazine. The clips are thrown away when empty, so that they must be made very cheaply. The main body of the clip is made from a sheet of brass stock about 0.021 inch thick by 2 7/16 inches wide. The sequence of operations necessary to complete this clip is illustrated from A to G in Fig. 3, and the machine for making the body of the clip is shown in Figs. 4 and 5.

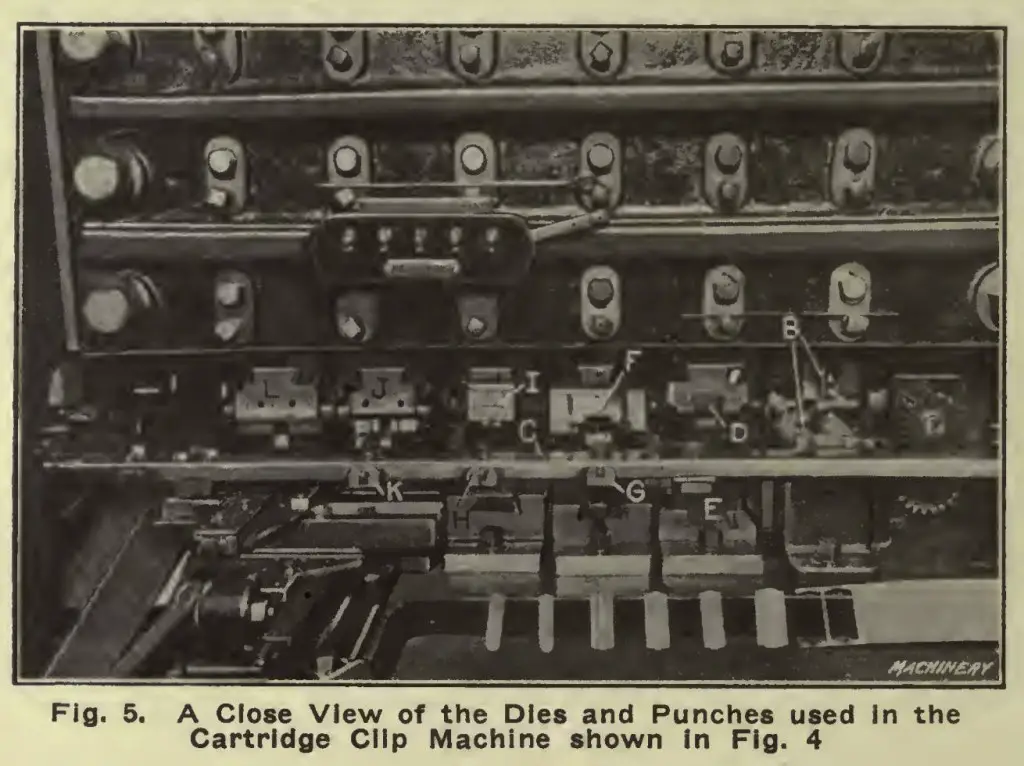

Referring to Fig. 4, which shows a front view of the press, the strip stock is held on a roll located at the right-hand end of the machine. The stock is fed into the machine by the ordinary type of feeding rolls, and the first operation is to cut out a blank as illustrated at A in Fig. 3. This is accomplished by the punch and die B, see Fig.5.

The blank is then ejected from the die and carried on to the next punch and die D and E by means of a transfer slide C similar to that employed in a multiple plunger press, that receives its motion from a crank mechanism at the left-hand end of the machine. The next operation, performed by the punch D and die E, is to form two ribs in the center of the blank, and turn up the two edges as shown at B in Fig. 3. The formed blank is then ejected and the transfer arrangement carries it on to the next operation, where punch and die F and G crimp the outer edges into the shape shown at C, Fig. 3. The edges of the blank are flattened down and at the same time turned up a distance about 3/64 inch above the top surface of the blank. The blank is then ejected from the die and is carried forward over die H. As punch I descends it forces the blank out of the transfer fingers and into the die H, This operation forms four projections which are shown at D in Fig. 3 that act as retainers for the spring to be inserted later. The next punch and die J and K draw up the sides of the clip into a box shape as at E, Fig. 3. Then, as the blank is passed on to the last punch L and its die, it is slightly curved and is ejected from the machine by a crank mechanism N, Fig. 4, which actuates the last die. This sequence of operations is carried on entirely automatically, and, in fact, the machine will run without any attention whatever until the roll has been exhausted. The operator then starts up the machine and the sequence of operations continues.

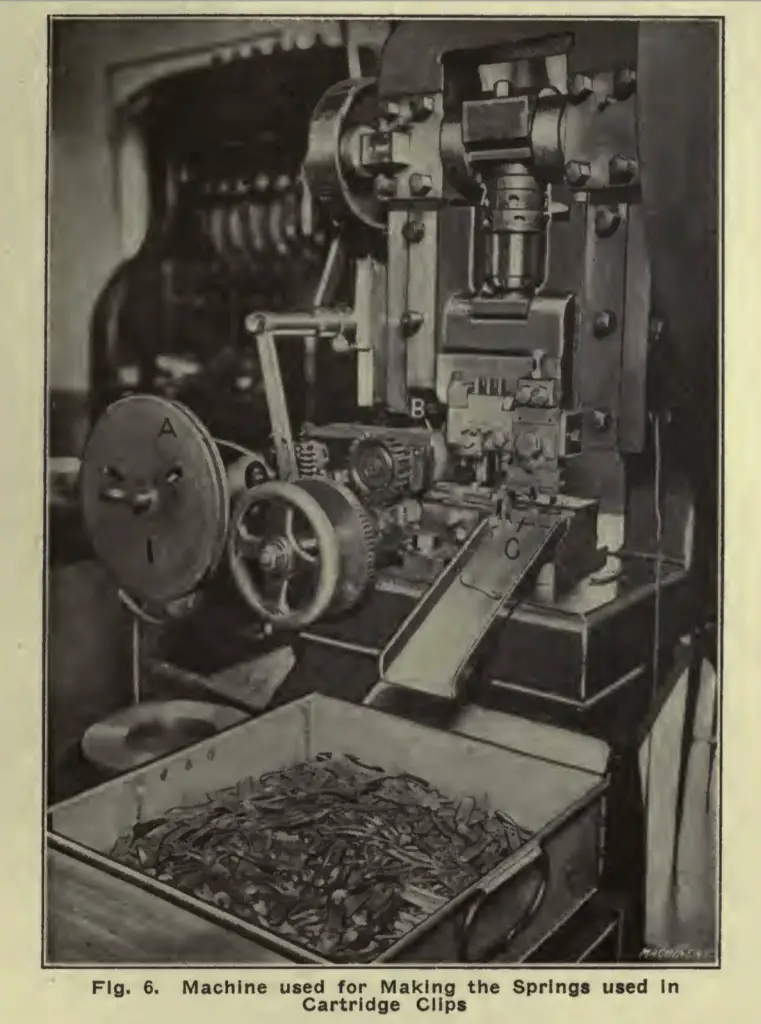

Making the Spring for the Cartridge Clip. —In order to hold the cartridge in place in the clip, a curved flat spring F, Fig. 3, is used. This spring, which is made from a sheet of half hard brass stock 0.510 inch wide by 0.010 inch thick, is blanked out and bent to shape in the press shown in Fig. 6. The stock is held on a roll A shown to the left of the machine, and is drawn in by a pair of ordinary feeding rolls B operated by a ratchet mechanism receiving power from the crankshaft of the machine. The first operation is to cut off a strip to the required length, form the ends, and pierce the three holes. This blank, by means of a carrier, is then transferred to the punch and die C. Here the blank is bent up into a curved shape and the spring prongs at each end are formed, after which it is ejected. These prongs are used in assembling the clips for holding the spring in place; they catch on a projection formed in the base of the clip. This machine is also entirely automatic in its operation, and, when once started, it will run until the roll of stock has been exhausted.

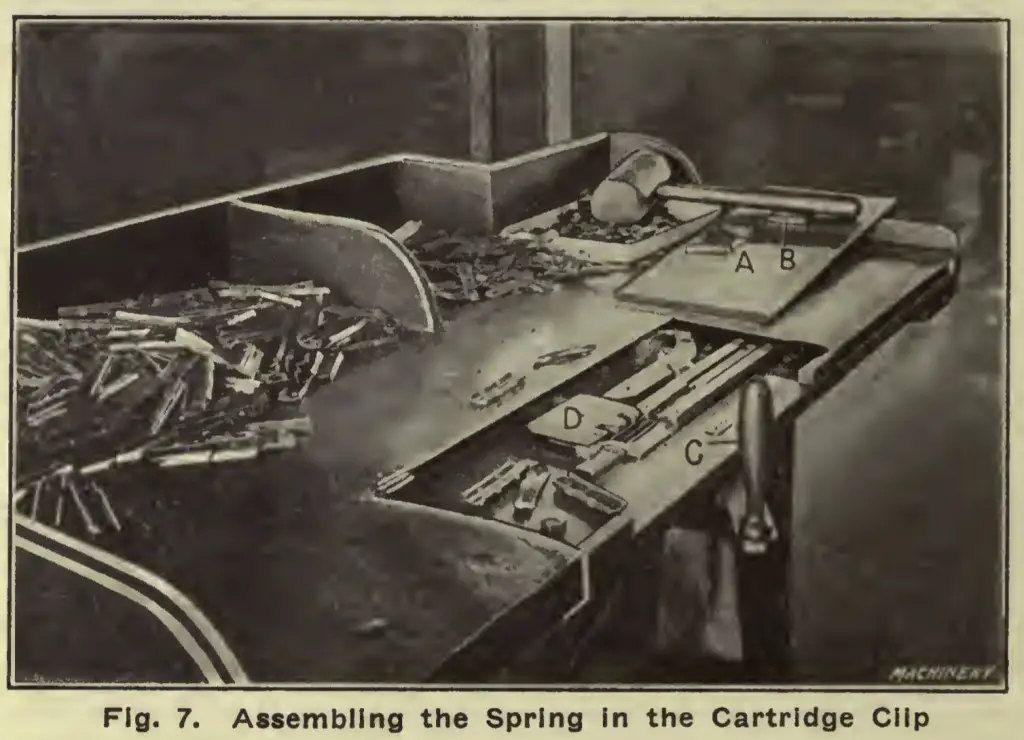

Assembling the Spring in the Cartridge Clip. —The assembling of the springs in the cartridge clip is accomplished in the small bench machine shown in Fig. 7. The operator places the clip in a nest, then inserts the spring in a slide which carries it forward and inserts it in the clip. The spring is held on this slide and is pushed into the clip automatically by the prongs which fit into the raised catches in the clip. The clip is carried forward into the assembling position by another slide, which works beside the spring-inserting plunger, and operates a carrier D, In order to show the working mechanism of this machine, the top lid or plate that covers the mechanism has been removed, and is shown to the right of the illustration. The clip is inserted through the hole A, and the spring in the hole B, When the operator pulls the handle C, the slide advances carrying the spring and assembles it in the clip. After assembling, the clip is ejected from the machine and drops into a box placed beneath it. The assembled clip appears at G in Fig. 3.

Gee, that looks like a mind-numbing job to us. And one easily automated. (It probably was, soon after 1916). The “machine” in this case is real Model T-era technology, a device that processes one part at a time and is powered by human muscle.

At this juncture, we have completed stripper clips, and elsewhere in the same book (see Source below) the entire process of completing ammunition, practically from raw materials, has been described and illustrated in similar depth and detail. What remains, then, is to inspect, clean and load the cartridges into the stripper clips. Onward!

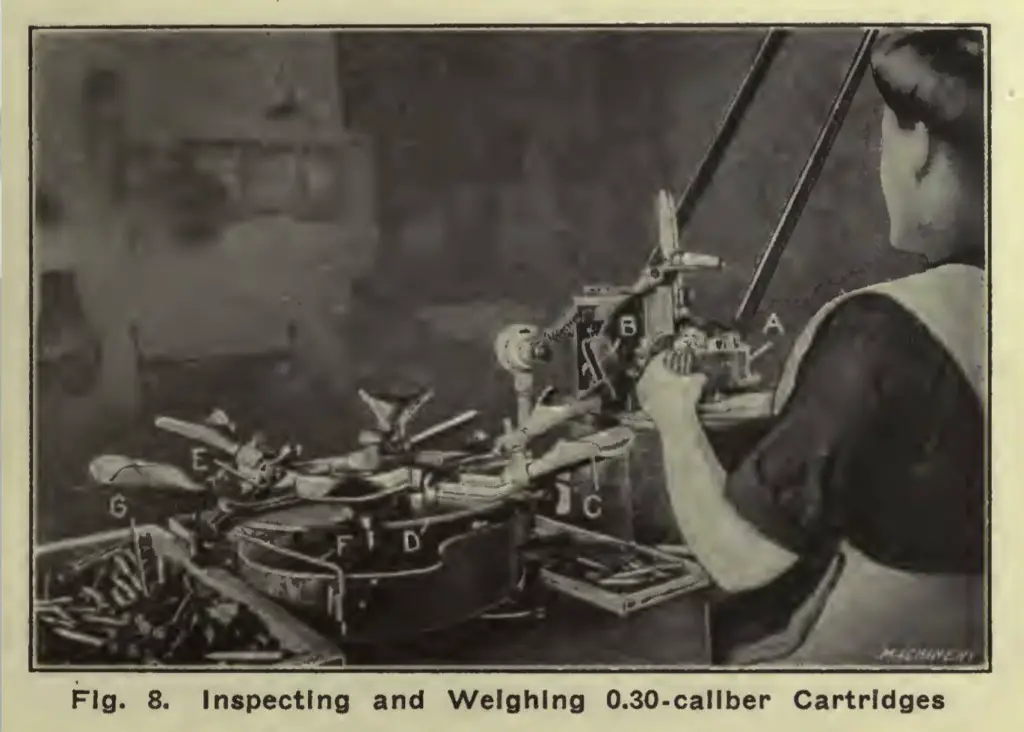

Gaging, Weighing, and Inspecting Loaded Cartridges. — Before locating the cartridges in the clip, they are inspected, gaged, and weighed. These three operations are all accomplished in one machine, which is shown in Fig. 8.

As you can see, this is another highly manual process. Note that in 1916, a century ago, there was no statistical quality control: every single round was subject to inspection. (Despite that… all the grenaded Springfields from Wednesday’s post?). We’ll continue with the explanation of what we’re seeing in Fig. 8 above.

The dies held in the dial A in which the cartridges are placed by the operator act as a gage for the body of the cartridge; that is, the contour of the holes in these dies is similar to the chamber of the rifle. As the dial passes around, the cartridges are carried beneath an electrically operated plunger which inspects them to see that each one has a primer in it. Should a cartridge be encountered that has no primer, this punch drops down into the pocket and breaks the electric circuit, which causes a bell to ring, thus notifying the operator that a cartridge with no primer has passed. When the primer is located upside down, the same action takes place. The cartridge is weighed in a unique and interesting manner. As the dial A passes around, the cartridge is lifted up and caught by the ejector B. This transfers the cartridge to the scoops C which are carried on the weighing dial D. The weighing is done by balances E in which the cartridges are deposited by the scoops C. The bullet comes up to a stop in these balances and a wire hook attached to the balance catches on the wire F when the cartridge carries the correct charge of powder and dumps the cartridge into the box G. When the charge of powder in the cartridge is light, the hook on the weighing balance E rides up over wire F, but as the dial passes around still further the hook catches on a wire located higher than wire F, and dumps the cartridge into the light charge box. It is therefore evident that cartridges which are light in weight pass the first box, but cannot go completely around, as they are ejected by the second wire, thus making certain of dumping the weighing balance and throwing the cartridge out. This mechanism successfully eliminates all light charge cartridges, and keeps them uniform in shooting quality.

That’s a bit of a Rube Goldberg machine, but there doesn’t seem to be any method of catching a heavy load. It is probable that a normal load filled the casing nearly brim-full and therefore a heavy load was not possible, practically.

Now it’s finally time to stuff the cartridges into the clips.

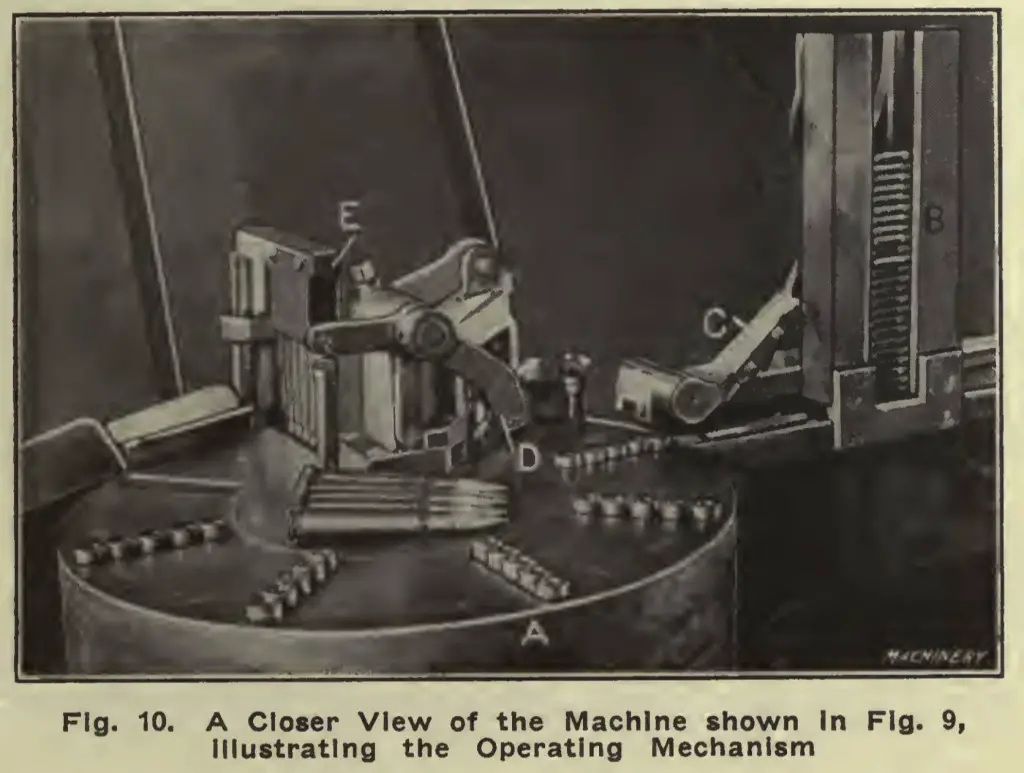

Inserting Cartridges in the Clips. —The machine used for inserting the cartridges in the clips is shown in Figs. 9 and 10. A dial A, which accommodates five cartridges in a row, carries the cartridges around to where the clip is inserted over them. This dial is rotated by means of a crank motion, pawl and ratchet in the ordinary manner, the ratchet dial being located beneath the dial carrying the cartridges. The assembled clips are placed in the proper position in the magazine B by an operator; two operators are engaged in keeping the cartridge dial full. The clip is carried out from the bottom of the magazine by means of a carrier operated by an eccentric shaft, and is located over the five cartridges in the dial A. The ‘”latch” C which is shown thrown back in the illustration runs under a roller held in bellcrank D and seats the clip properly on the heads of the cartridges. The dial then indexes to the next position, where a bending tool comes into action and bends down the prong projections on the ends of the spring in the clip, thus preventing the cartridges from dropping out. As the dial then indexes around to the next position, the cartridges that have been inserted in the clips are picked up out of the dial by means of a swinging transferring arm that drops them in a box; 65,000 of these cartridges are inserted in the clips per day of eight hours. Fig.10 shows a closer view of the machine illustrated in Fig. 9, and gives a better idea of its construction and operation. Here it will be seen that the ejecting or work-removing fixture is composed of two pieces of sheet steel, spring tempered, which grip the clip by the lower surface.

* The term “clip” has been used here, as that Is the name used by the U.S. Army; this part, however, should be properly called a “charger.”

It would be interesting to compare this line to how Mauser’s guys were doing it in Teutonistan, but we’re not aware of any analogous German source.

This is a chapter of a 1916 book, Cartridge Manufacture, by Douglas Hamilton, who was then Associate Editor of the trade magazine Machinery. (We’re looking for Hamilton’s other works in ebook or hard copy, including “Shrapnel Shell Manufacture.”

Complete bibliographical information — and perhaps of more immediate use to you, a .pdf of the document, courtesy Microsoft Corporation — follows.

Source

Hamilton, Douglas T. Cartridge Manufacture: A Treatise Covering the Manufacture of Rifle Cartridge Cases, Bullets, Powders, Primers and Cartridge Clips, and the Designing and Making of the Tools Used in Connection with the Production of Cartridge Cases and Bullets, Together with a Description of the Principal Operations in the Manufacture of Combination Paper and Brass Shot Shells. New York: The Industrial Press, 1916.

Available here: cartridge_manufacture_hamilton_1916.pdf (12.4 MB .pdf file, color).

Don’t Forget Forgotten Weapons…

… although, it could be called “Remembered Weapons,” because Ian remembers all the stuff that everybody else has forgotten. True, we haven’t flagged you to his site in, what, two whole days? But when he’s posting stuff like this, you need to be over there, not here. We’ll still be here posting several times a day, but trust us, you want to see these two posts, and you want to point your RSS reader at FW so you never miss stuff like this.

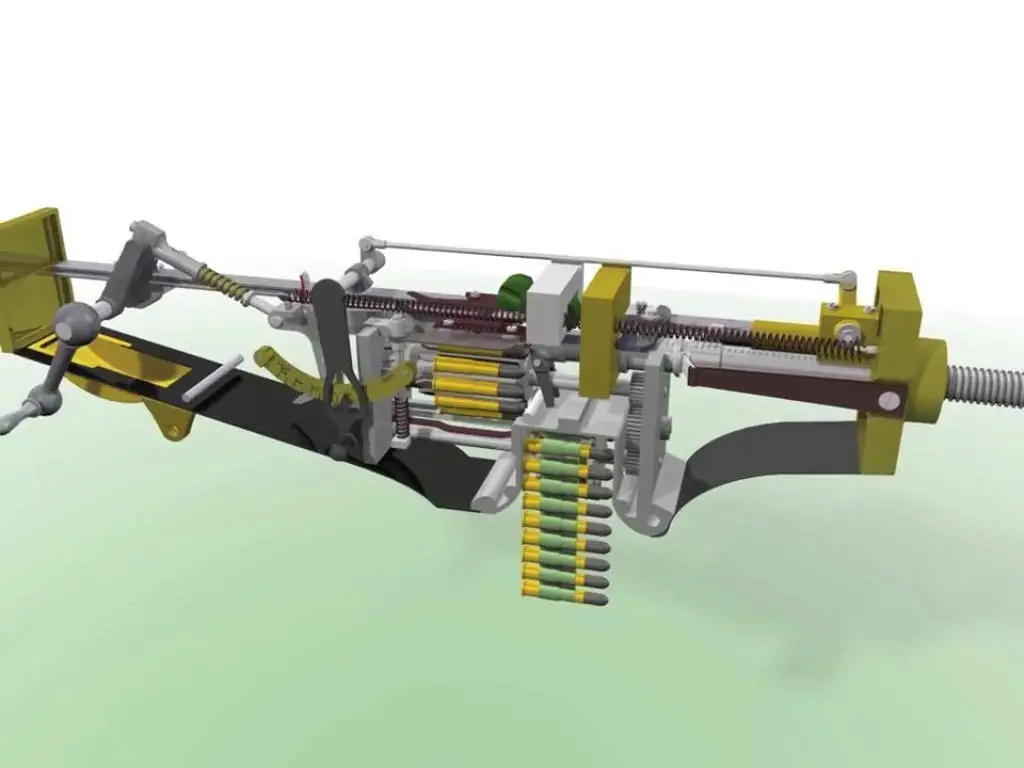

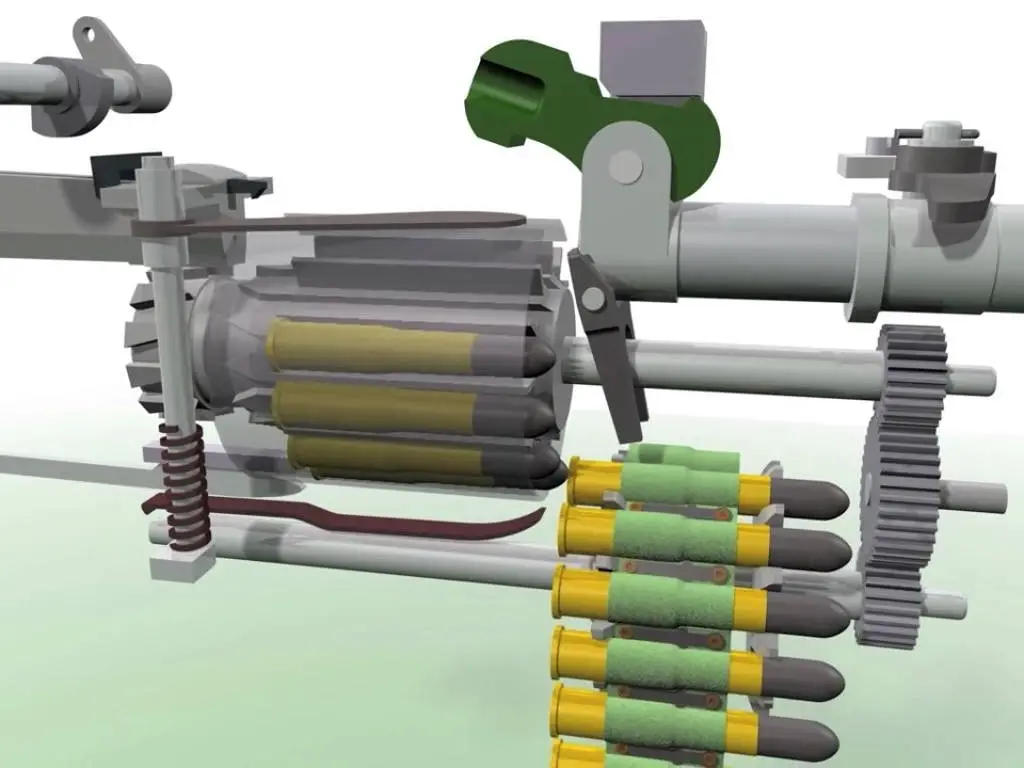

Item: The Grandpappy of all MGs

Every gun begins with the prototype — no, wait… Every gun begins with an idea, but it has to pass through the stage of prototype if it’s ever going to be made concrete and marketed, adopted, and/or produced. And Forgotten Weapons is starting a new series on the Maxim, the grandpappy of all machine guns, with a great post on the prototype, which is, naturally, the granddaddy of all Maxims.

One of the best parts of that post is a video Ian scared up which shows the ur-Maxim’s inner cuckoo clock. It’s ingenious, but it’s fair to say that the highly developed Maxim of the First World War was vastly simplified and improved over this design.

That, of course, just makes the engineering dead ends of the prototype even more interesting. There’s a little bit of similarity to the much later aerial weapon, the Mauser revolver cannon, in that a rotary sprocket is used to lift the cartridges after they are withdrawn by an extractor from the ammunition belt.

Item: Small Arms Development, 1945-65: the Soviet View

Victory Day parade. Rather than rest on their laurels, the Soviets overhauled their weapons after World War II, sending these Mosins to the warehouse, and by 1965 they’d done it a second time.

Ian got hold of a fascinating primary source document: a CIA translation of a classified Soviet analysis of small arms development after World War II. Both the intent of Soviet development and the differences between Soviet and NATO small arms doctrine and development objectives are laid bare in this document (available at the link).

Our long-held thesis that Soviet developments were primarily focused on putting automatic fire in the hands of their riflemen, whereas Western forces primarily focused on aimed semi-auto fire, is borne out from the horse’s mouth, as it were. The authors of the piece, two senior Soviet officers, see, from their point of view, 1965 NATO as making a serious error in not giving their riflemen weapons that can be effective in automatic fire at close range. Of the US Army:

[E]xperience in the operation of the M14 rifle has shown that it has extremely unsatisfactory grouping capability during automatic firing, as a result of which it is assigned to US troops only in the semiautomatic variant.

…in recent years the American army has renovated nearly all of its small arms. However, it should be pointed out that with the NATO cartridge as a basis, the USA has failed to solve the problem of developing a mobile and effective automatic individual weapon that satisfies the requirements of modern combat. For this reason the Americans have taken measures to modernize the M14 rifle, to explore other rifle designs, to develop a new 5.6-mm cartridge with reduced power, and to develop a rifle that will use this cartridge.

Ivan also prized light weight in his weaponry.

With allowance made for [the Soviets not being sure what NATO armies carried as a basic load of ammunition -Ed.] the average weight load (weapon plus unit of fire of cartridges being carried) per man amounts to: in the Soviet Army — 7.2 kilograms, in the US Army — 9.3 kilograms, in the West German Army — 10.9 kilograms, and in the French Army — 8.5 kilograms,

(This is referring to the M14 version of the US Army, the one that faced Russian occupation armies in Eastern Europe directly at the time. Elsewhere in the report, they note the emergence of the M16 as something to be watched).

Judged on the basis of these data, the weaponry of the Soviet Army is the lightest. This has been achieved by the use in our army of the 7,62-mm Model 1943 cartridge and the development for it of an automatic rifle and a light machinegun, which have made it possible to substantially lighten the weight of both the individual weapon itself and also the unit of fire carried with it.

Interesting to us that no credit at all is given to the Germans for inventing the intermediate cartridge and assault rifle concept. While the CETME rifle is mentioned as the source of the German G-3, there’s no mention that the CETME itself is an adaptation of the StG.45. (That fact may have been unknown to the Russian authors).

The authors were extremely satisfied with the state of Soviet weapons, and considered their weapons superior both individually to their counterparts, and on a unit vs. unit basis.

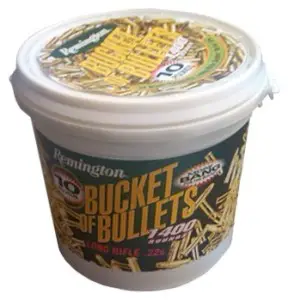

What’s up with .22 Ammo?

As those of you who are either buying or selling (or even window shopping) know, while the shortage of center-fire ammunition has eased (as production has caught up with higher demand), rimfire ammo remains in short supply.

As those of you who are either buying or selling (or even window shopping) know, while the shortage of center-fire ammunition has eased (as production has caught up with higher demand), rimfire ammo remains in short supply.

In fact, it’s being produced in record volumes; it just continues to be bought and hoarded. As the shortage has eased just a little, internet retailers have occasionally had small stocks, and gun shops have been able to keep the pricier specialty ammunition, like match and premium-priced suppressor loads, on the shelf. This signals that supply has eased enough for price discrimination and elasticity to return, at least partially. But the market remains roiled by waves of demand that exceed the supply of bulk packed and economy rimfire ammunition.

Several things have, in our opinion, changed the dynamics of the ammunition market on a durative (not permanent, but long-term) basis. Those include:

- Lack of market substitutes for rimfire ammo. If you’re shooting a rimfire match, plinking, hunting small game, or introducing new shooters to the sport, the humble .22 long rifle cartridge is in a class of its own. Also, if you have guns chambered for rimfire, they’re useless without ammo. Finally, unlike centerfire ammo, .22LR is not practically reloadable. (Yes, we’ve seen the websites and tutorials. We said “practically” and we stand by that).

- Very high cost of market entry, long lead times on increasing production, and inflexibility of rimfire production equipment. A rimfire production line is not readily adaptable for any other purpose, while a centerfire production line can change calibers to meet demand. Few firms worldwide produce the required machinery, and they too have been saturated with demand.

- Continued gun-ban rhetoric from blue-state (and beltway-fied red state) politicians, including direct threats to the availability of ammunition in quantity and via internet purchase.

- A traumatized market after years of shortage, which encourages hoarding. Before 2008, nobody bothered to keep tens of thousands of rimfire rounds on hand, because it was pervasively available and cheap. For years, especially beginning in 2012 when the probability of a second anti-gun Obama administration became clear, the shelves have been denuded more quickly than they can be restocked.

- Finally, the many new shooters introduced over the last few years, perhaps another consequence of the ban threats (in this case, inducing fence sitters to jump in to the rodeo), means that hoarding aside, the permanent level of demand is at a new, higher level.

As it happens, Frank Brownell polled his ammunition industry contacts and came up with some similar ideas. Here’s what he wrote in a recent newsletter to Brownell’s customers:

Here’s the scoop from some of our industry friends who are really plugged into the ammunition business. It’s not as bad as it was. Rimfire ammo IS making its way onto store shelves, but demand is still sky high, so it zooms off those shelves almost instantly, usually with a limit on the number of boxes you can have.

Premium brands of .22 LR are sticking around longer in stores because customers who were willing to pay high prices just to get any .22 ammo have slowed down their buying. But the less-expensive ammo – the “buy a brick and plink all Saturday afternoon” stuff – still gets gobbled up as soon as it hits a shelf.

The biggest issue is, unlike centerfire ammo, rimfire is produced on dedicated machinery that can only load rimfire. Centerfire machines can load many different cartridges, so if there’s a big shortage of .308 Winchester, the ammo factory can switch a bunch of machines over to it and ramp up supply much faster. That’s why calibers that were in short supply in 2013 and 2014, like 9mm or .223 or .45 ACP, came back a lot faster.

Rimfire is a whole other ball of wax because of the way the cases are primed. It’s really, really expensive and takes a long time to set up new rimfire production machinery – so costly that manufacturers can’t spend the time and money to do it unless they’re absolutely sure higher demand is here to stay, so the .22 LR production capacity in the U.S. isn’t going to expand much any time soon. As long as demand for less-expensive rimfire ammo remains so strong, it will continue to be hard to get. Our guys tell me supply will probably stay very tight right through 2016. Wish I had better news – as soon as I do, you’ll be the first to know!

Frank’s news that 2016 will continue to be a dry gulch for .22LR is depressing, but one factor he mentions is something we hadn’t considered — the costs of new entry being so high that, even in the face of this demand, producers have shrunk from expanding production capacity lest they be caught with their pants down, indebted for production capacity that’s excess when the music stops.

It sounds like there’s a real market opportunity for someone that can design and engineer a lower-cost, lower-footprint, more flexible (and while you’re at it, why not more consistent, thus higher-quality) rimfire production line. We don’t see why this can’t be done from a clean sheet of paper and produce two relatively small-footprint machines, one that goes from rod to blank to finished, unprimed cases, and one that primes and loads the cases, for a half-million per installation, and maybe for half that.

What are we missing?

CMP 1911 Sales in the NDAA; Threatened Veto; Capped at 10k Firearms

The authorization for the Department of Defense (NDAA FY 2016) includes the statutory language changes needed so that the Army may begin transferring the approximately 100,000 surplus M1911A1 pistols in its warehouses to the Civilian Marksmanship Program for sale to CMP member/customers. However, the bill must be signed by the President to become law, and it has many provisions (including this one) that he finds unpalatable. He has threatened to veto the bill, and it is unlikely that any of his fellow Democrats would help override his veto.

The authorization for the Department of Defense (NDAA FY 2016) includes the statutory language changes needed so that the Army may begin transferring the approximately 100,000 surplus M1911A1 pistols in its warehouses to the Civilian Marksmanship Program for sale to CMP member/customers. However, the bill must be signed by the President to become law, and it has many provisions (including this one) that he finds unpalatable. He has threatened to veto the bill, and it is unlikely that any of his fellow Democrats would help override his veto.

Even if he doesn’t fold before Congress like he’s so pleased to do for Khamenei and Putin, the bill is not the CMP free-for-all that pistoleros have been expecting. It requires CMP to jump through some hoops and add further of the politicians’ favorite buzzword, “background checks.” (CMP already conducts a NICS check on its rifle sales, so it’s unclear what the bill’s provision really does). It gives great authority to the Secretary of Defense, which he may use obstructively, if he desires to kneecap the program. There are reports required. And most vexingly, the program is limited to a pilot program of 10,000 in the first year, and then, if that is successful, 10,000 a year thereafter. The conference committee language is available at congress.gov, although it’s not entirely clear when the bill, the final form of which was voted on by both houses last week, will make its way to the other end of the Mall for veto or signature. The text of the main part of the relevant section follows, then some brief comments. We’ll intersperse GI 1911 pictures, to prevent the Wall O Legalese from sending you into MEGO (My Eyes Glaze Over) Mode.

Sec. 1087. Transfer of Surplus Firearms to Corporation for the Promotion of Rifle Practice and Firearms Safety.

(a) Authorization of Transfer of Surplus Firearms to Corporation for the Promotion of Rifle Practice and Firearms Safety.-

(1) In general.-Section 40728 of title 36, United States Code, is amended by adding at the end the following new subsection:(h) Authorized Transfers.-(1) Subject to paragraph (2), the Secretary may transfer to the corporation, in accordance with the procedure prescribed in this subchapter, surplus caliber .45 M1911/M1911A1 pistols and spare parts and related accessories for those pistols that, on the date of the enactment of this subsection, are under the control of the Secretary and are surplus to the requirements of the Department of the Army, and such material as may be recovered by the Secretary pursuant to section 40728A(a) of this title. The Secretary shall determine a reasonable schedule for the transfer of such surplus pistols.

2) The Secretary may not transfer more than 10,000 surplus caliber .45 M1911/M1911A1 pistols to the corporation during any year and may only transfer such pistols as long as pistols described in paragraph (1) remain available for transfer.

This is followed by a section of “technical and conforming amendments” that essentially patch other laws that would otherwise conflict with the policy change imposed by the paragraphs above. Then come the exceptions, limitations and reporting requirements:

(b) Exception.-With respect to firearms other than caliber .22 rimfire and caliber .30 rifles, the corporation shall obtain a license as a dealer in firearms and abide by all requirements imposed on persons licensed under chapter 44 of title 18, including maintaining acquisition and disposition records, and conducting background checks.”.

(b) Pilot Program.-(1) One-year authority.-The Secretary of the Army may carry out a one-year pilot program under which the Secretary may transfer to the Corporation for the Promotion of Rifle Practice and Firearms Safety not more than 10,000 firearms described in paragraph (2).

(2) Firearms described.-The firearms described in this paragraph are surplus caliber .45 M1911/M1911A1 pistols and spare parts and related accessories for those pistols that, on the date of the enactment of this section, are under the control of the Secretary and are surplus to the requirements of the Department of the Army.

(3) Transfer requirements.-Transfers of surplus caliber .45 M1911/M1911A1 pistols from the Army to the Corporation under the pilot program shall be made in accordance with subchapter II of chapter 407 of title 36, United States Code.

(4) Reports to congress.-

The reports are spelled out in the Conference Committee report, but they basically are one three months in and one at the end of the year, send Congress the total firearms transferred, and any of these firearms reported as being used in crimes. (With the guns likely to sell in the low four figures and up, any that make it into criminal intercourse will almost certainly have been stolen, but Congress wants the report).

And one last provision:

(c) Limitation on Transfer of Surplus Caliber .45 M1911/M1911A1 Pistols.-The Secretary may not transfer firearms described in subsection (b)(2) under subchapter II of chapter 407 of title 36, United States Code, until the date that is 60 days after the date of the submittal of the final report required under subsection (b)(4)(B).

If we read the statutory reference right (which is always a crapshoot), what this provision does is forbid the Army to transfer any newly recovered foreign aid or lend-lease .45s that are in foreign inventories and sell them, before the final report on the pilot-program year is submitted. It is unlikely that any such transfers would happen in the Obama administration, which has argued with a straight face that $1,000, four-foot-long M1 Garands and $1,500 collector carbines are widely used in crime.

Other Small Arms Provisions

Other Small Arms provisions in the NDAA include a requirement for a Report on the Army and Marine Corps modernization plan for small arms (sec. 162), and a requirement that an independent assessment compare the vulnerability to small arms and light AA of the A-10, which the USAF is anxious to scrap, to its recommended replacements (sec. 142).

Section 142 (e) (1) (b) (i.) (VI) (Some punctuation added for clarity):

Future needs analysis for the current A-10 aircraft mission set, to include: troops-in-contact/close air support, air interdiction, strike control and reconnaissance, and combat search and rescue support in both contested and uncontested battle environments. At a minimum, the needs analysis should specifically address…[t]he capability to enable the pilot and aircraft to survive attacks stemming from small arms, machine guns, man-portable air-defense systems, and lower caliber anti-aircraft artillery organic or attached to enemy ground forces and maneuver units.

A Congressional brush-back pitch on the USAF’s desire to decommission the A-10. They should just transfer ’em to the Army (as if), since outside the A-10 community the leaders’d rather not do CAS anyway (the pilots are a different story… there’s a lot of gung-ho in line squadrons).

Sec. 162. Report On Army And Marine Corps Modernization Plan For Small Arms.

(a) Report Required.-Not later than one year after the date of the enactment of this Act, the Secretary of the Army and the Secretary of the Navy shall jointly submit to the Committees on Armed Services of the Senate and the House of Representatives a report on the plan of the Army and the Marine Corps to modernize small arms for the Army and the Marine Corps during the 15-year period beginning on the date of such plan, including the mechanisms to be used to promote competition among suppliers of small arms and small arms parts in achieving the plan.

(b) Small Arms.-The small arms covered by the plan under subsection (a) shall include the following:

(1) Pistols.

(2) Carbines.

(3) Rifles and automatic rifles.

(4) Light machine guns.

(5) Such other small arms as the Secretaries consider appropriate for purposes of the report required by subsection (a).(c) Non-standard Small Arms.-In addition to the arms specified in subsection (b), the plan under subsection (a) shall also address non-standard small arms not currently in the small arms inventory of the Army or the Marine Corps.

This provision was originally in the Senate, but not the House, bill. The House yielded to the Senate language. The justification of this seems clear enough. The services seem determined to look like they’re flying by the seat of their pants here, with no forethought, let alone planning. This is a brushback pitch from Congress. Subtext: figure out a plan and show us what it is, or we might strangle the money you’re expecting.

Section 163. Study On Use Of Different Types Of Enhanced 5.56mm Ammunition by The Army And The Marine Corps.

Left: M855A1, 62 grain; Right: Mk 318 OTM/SOST, 62 grain. Image from Rod Rodriguez’s Grunts & Co. blog.

Rather than provide the text of this, just note that it requires the SecDef to appoint one of the Federally Funded Research and Development Centers to evaluate how the Army and Marines came to adopt different 5.56mm ammo, and suggest courses of action. The full text is available at the link.

In this case, the House had a provision for a report, and the Senate did not. In conference committee, the two houses agreed to a report but required it be done by a nominally independent FFRDC (the committee language mentions the Center for Naval Analyses as an example, but there are others including the RAND Corp, the Institute for Defense Analyses, MITRE, etc., etc.)

On this, one of the best things we’ve seen is Will “Major Rod” Rodriguez’s painstaking explanation of what went into M855A1 (Army) and Mk 318 SOST (Marine/SOF) ammo. The bottom line is both beat M855 green tip for accuracy, barrier-blindness, and terminal effect. We stole Rod’s graphic too… sorry about that.

How Criminals Gun Up in Shreveport: With Cop Guns

Officer Thomas LaValley of the Shreveport, LA police was ambushed and killed two weeks ago. His murderer took his Glock, a fact the police department initially covered up.

At least ten more department pistols are missing, including one stolen in February along with the officer’s badge, radio and protective vest.

Shreveport police revealed Wednesday officer Thomas LaValley’s service weapon is missing. It’s been two weeks since the officer was killed answering a suspicious person call.

That’s all police are saying.

“We’re not ever going to do or say anything that would potentially compromise the operational integrity of an investigation,” SPD chief administrative assistant Bill Goodin said.

Shreveport police in February said there are at least 10 pistols missing from their inventory. Now LaValley’s Glock gone.

Police think Grover Cannon, the suspect in the slaying, stole the weapon. Cannon is in custody and is not cooperating with the search for the gun, police said.

via Few details available on LaValley’s missing firearm.

A lot of people seem to think that if we did X, Y or Z we could end “gun violence,” as if the Grover Cannons were getting their cannons from Cabela’s. Unfortunately, as records show, Grover and his ilk can get guns from family and friends, from criminal associates, from theft from legitimate users, and even by murdering police officers.

Guns do make suicide very easy, and that’s why purveyors of instant “gun violence” solutions like to use “gun violence” numbers that include self-destruction along with accidents and homicides (lawful and unlawful). These people are sincere, but their thinking doesn’t reach the necessary depth. For instance, on suicides, it doesn’t occur to them that suicidal intent will seek a weapon of opportunity, and given the fragility of Homo sapiens, such a thing is always at hand. Nobody really knows how much locking up weapons (or, for example, fitting bridges with jumper nets) deters suicide, versus how much it merely displaces it to a less inconvenient method. For instance, on homicides, it doesn’t occur to them that the thing differentiating a spree shooter from a gun collector — murderous intent — is the same thing differentiating a serial slasher from a gourmet chef. The gun, the knife, are mere implements in a hand guided by a mind — the chef’s knife and the murderer’s may be the exact same tool, but one is guided by a creative mind and one by homicidal impulse.

Grover Cannon would still be a threat if he never owned anything that is not your kitchen. It is not late Officer Lavalley’s gun, or the gun he allegedly killed Lavalley with, that made him a threat. It was his heart and his mind that made, and makes, him a threat.

You could make every gun in the world disappear with a magical incantation, and Grover Cannon would still be a threat, a toxin, a pathogen. You could give the Dalai Lama a nuclear bomb and he would be no more a threat than he is now.

When a man’s heart and mind is a threat, he is never disarmed.

Mossberg .22 kB!

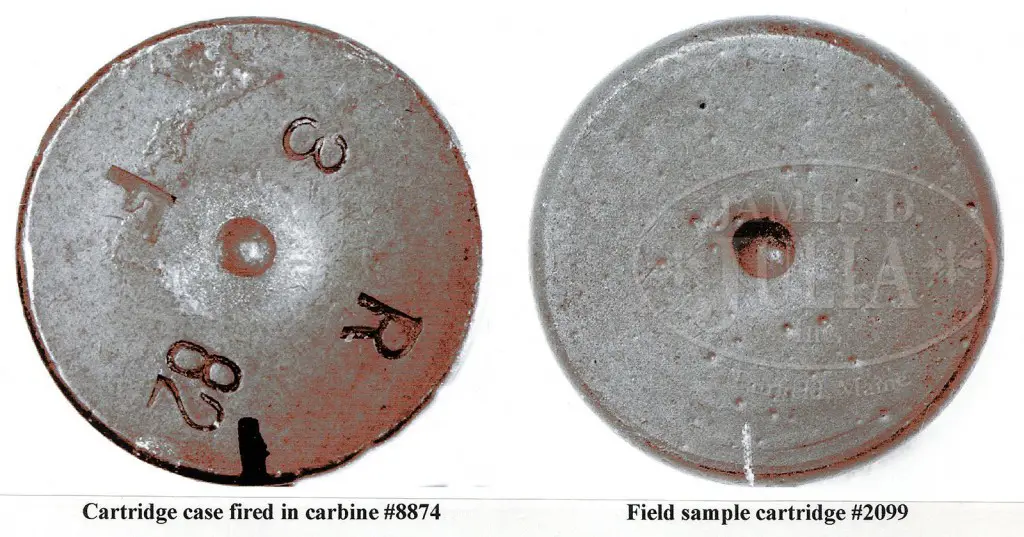

This is what an out-of-battery fired .22LR round looks like, afterwards.

Minus, of course, any parts still embedded in the shooter.

You can see what looks like a light firing pin strike at about 4 o’clock. It probably looks light because it was light, because the rim was not fully supported by the chamber when the striker or firing pin struck the case head. But it was supported enough for the primer to fire, with the results you see here. Lucky the shooter wasn’t left-handed, or he might have been plucking that brass out of his face.

From /r/guns:

Was shooting my mossberg 702 (i know get the 702 bashing out of your system if you need to) that i have put a couple thousand rounds through since i have had it, this particular rifle always had minimal malfunctions for me and that is why i held on to it. Most of the time a little spray of clp and it will keep running fine. But today i was shooting federal bulk pack and all was going well until this round exploded and sprayed my hand with debris.

My assumption is that it was not fully into battery when i pulled the trigger resulting in the casing basically banana peeling and ripping in half.

Moral of the story is the value of safety glasses because who knows what kind of shit would have been sprayed in my eyes.

via This is why we wear safety glasses : guns.

A gun shouldn’t be able to fire out of battery. We mean, it should be physically impossible, if the designer was remotely competent. John M. Browning’s guns have safe designs that will not fire out of battery, and he’s been dead since Silent Cal was President.

We don’t know if the gun was stock or modified. There are a number of instructions for doing a Bubba job on the Mossberg 702 / 715 trigger mechanism on the net, for example here’s an Instructable on it. Owners who hack a trigger they don’t understand — and anybody who writes about the “seer” probably doesn’t understand — are the sort of thing that gives gun-company lawyers sleepless nights. One of the things that can cause out-of-battery firing is an improper trigger mechanism, which can be caused by bad design, manufacture, or subsequent modification. Disconnecting or blocking the firing mechanism until the bolt is fully seated is a fundamental requirement of trigger mechanisms.

Without doing surgery on a sample of 702s, ideally including the mishap firearm, we can’t say what provisions are made for safing the gun until complete bolt closure, or why they failed in this case.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.