In Monday’s installment, we gave you the overview of the SAW program as of 1979, and we looked in depth at the least radical design, the magazine-fed M16 variant, XM-106 automatic rifle, a product of the Army’s own Ballistic Research Laboratory. Today’s installment will fill you in with a little more on the competition and its history, and will go into a little depth — unfortunately, a little depth is all we have — about the XM-248 and especially its forerunner, the XM-235.

To recap, as of the beginning of 1979 four candidates were being compared for a concept of a Squad Automatic Weapon that was then (barely) filled in the infantry fire team by giving one guy a stamped-steel bipod and permission to set his selector to Crowd Control. Along with the XM106, which was an M16A1 with some concessions to firing high rates and volumes of automatic fire, the contenders at this point were three belt-fed 5.56mm light machine guns: Ford Aerospace’s XM248, FN’s XM249 and H&K’s XM262.

The XM-248 is a good-looking gun with a straight inline mechanism and a very clever belt feed that had the potential to be more positive, but less upsetting to accuracy, than the typical feed tray that’s been standard on GPMGs ever since the MG34 instantiated the category way back during the Great Depression.

To understand the XM248, we have to roll back a bit, to the very dawn of the SAW program in 1975 (the term “SAW” dates to 1970, and the idea of an intermediate gun between the rifle and the 23+lb M60 GPMG dates to 1966). The Army’s Training and Doctrine Command had noted that a war in Europe was possible, and Europe was vastly more built-up than in the last war. Even then, much of the fighting was in cities — dismounted infantry terrain. A squad automatic weapon that could deliver fire in high volumes would benefit such a squad, in what the Army now calls Military Operations in Urban Terrain (MOUT) and then called Military Operations in Built-up Areas (MOBA). So in 1975, the Army began designing in its own labs, and calling for, from industry, a new weapon, at the same time it began to evaluate M16 improvements that would lead (through a winding path blazed mostly by the USMC) to the M16A2. Both improvements were aimed at MOBA as well as just generally increasing the lethality of the squad, and drew upon TRADOC studies that said fire volume was more important than fire precision.

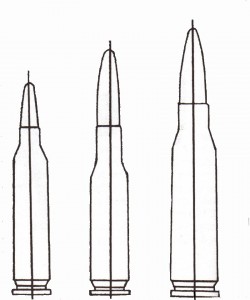

The new SAW — the squad’s volume-fire weapon — would use either an optimum cartridge or the standard rifle cartridge. (Each approach had its adherents). The first round of paper SAW candidates were chambered for disparate cartridges, including a new experimental 6mm and the standard 5.56mm. The 6mm fired a 105-grain projectile at 2450 fps (6.8g/.747m/s) compared to the M193 round’s 55gr/3250fps (3.5g/990m/s), giving the new MG a range beyond 800m. One of the main drivers of the 6mm caliber wasn’t anything to do with ball ammunition — it was that given the tracer technology of the time, no known compound could trace to and beyond 800m in daytime, and be contained in the volume of a 5.56mm projo. Army ordnance guys really liked the 6mm; loggies, and the senior generals who would have to square a new caliber with our NATO allies, were more reserved, for entirely non-technical reasons.

Because it was no longer in production or actively being promoted, the Stoner XM207E1 was out of the picture. In any event, the Army’s ordnance officers had a strong prejudice against it: the SEALs loved the gun and used them until there were no parts to be had, but the Army considered it too maintenance-intensive to be reliable in the hands of draftees with GT Scores of 80. Likewise, Colt’s CMG-2; and like other guns rejected before the contest began, they fired the 5.56mm cartridge, which didn’t meet the Army’s desire for an 800m+ weapon.

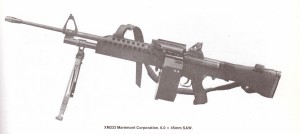

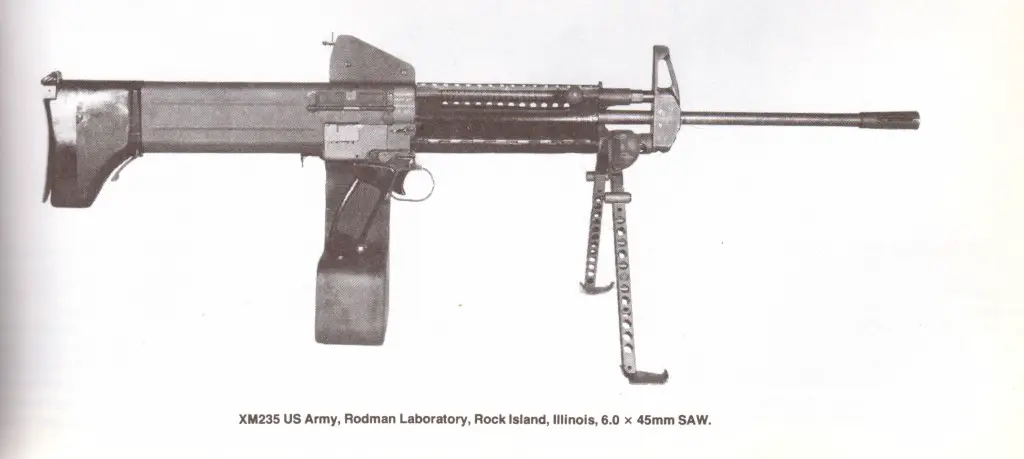

The three contenders in the 1975-76 round were made for the 6×45 cartridge and given sequential model numbers. XM233 (left) was Maremont’s entry. As you might expect from the maker of the M60, it looked like a baby 60. The XM234, a spindly-looking thing, was prototyped by Philco (about which, more below). And the Army’s own Rodman Laboratories (at Rock Island Arsenal in Illinois) developed a radically new concept which was labeled XM235.

The three contenders in the 1975-76 round were made for the 6×45 cartridge and given sequential model numbers. XM233 (left) was Maremont’s entry. As you might expect from the maker of the M60, it looked like a baby 60. The XM234, a spindly-looking thing, was prototyped by Philco (about which, more below). And the Army’s own Rodman Laboratories (at Rock Island Arsenal in Illinois) developed a radically new concept which was labeled XM235.

Two more-familiar 5.56mm guns that were being developed in Europe and entirely outside the Army competition at the very same time were not considered at this time: the FN Minimi and the H&K HK23. Ironically, they were rejected specifically because they were 5.56mm weapons. But we haven’t heard the last of the little round and these two commercial guns, either, because in Developmental Test/Operational Test 1, they, and a heavy-barreled variant of the M16, were used as controls and benchmarks for the “real” 6mm guns.

Philco’s 6mm gun was called the XM234, and it looked like this:

And that picture is almost all we know about it. At the time, we recall reading, and laughing about, the idea that Philco had entered a gun in the Army competition. Philco was the subsidiary of Ford that made the radios and 8-track players (don’t we keep telling you, The Past Is Another Country? Some of us lived there). And so, the idea of it making machine guns was pretty funny. But Detroit automakers are no slouches on mass production, and the Army has often turned to them when it needed quantity and quality. In World War II, the Navy threw a young officer named Henry Ford II out so he could take over from his ailing father and take charge of Ford’s war production, which included guns, gun parts, and complete B-24 Liberators. GM made M3 grease guns, and later would produce M16A1s with considerably less drama than Colt, despite a rather lacking Technical Data Package. So, Philco probably could make a gun; auto manufacturing technology was effective for guns; and mechanical engineering is the same discipline of materials, statics and mechanics for a gun designer that it is for a guy designing a valve train or power-steering mechanism.

By the time the 11th Edition of Small Arms of the World, from which a number of these facts and photos are taken, was published in 1977, the defense branch of Philco had taken on the more dignified name, Ford Aerospace & Communication Corporation.

There’s very little information about the Philco entry available, especially online; and at the end of the first phase, DT/OT1, in December, 1974, both its gun, the XM234, and Maremont’s weren’t what Army evaluators were interested in. But they really liked the Army’s entry, the XM235:

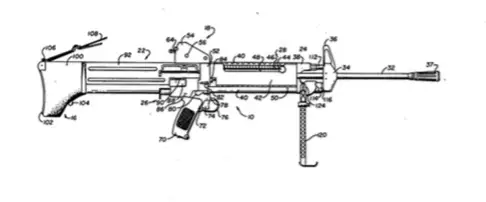

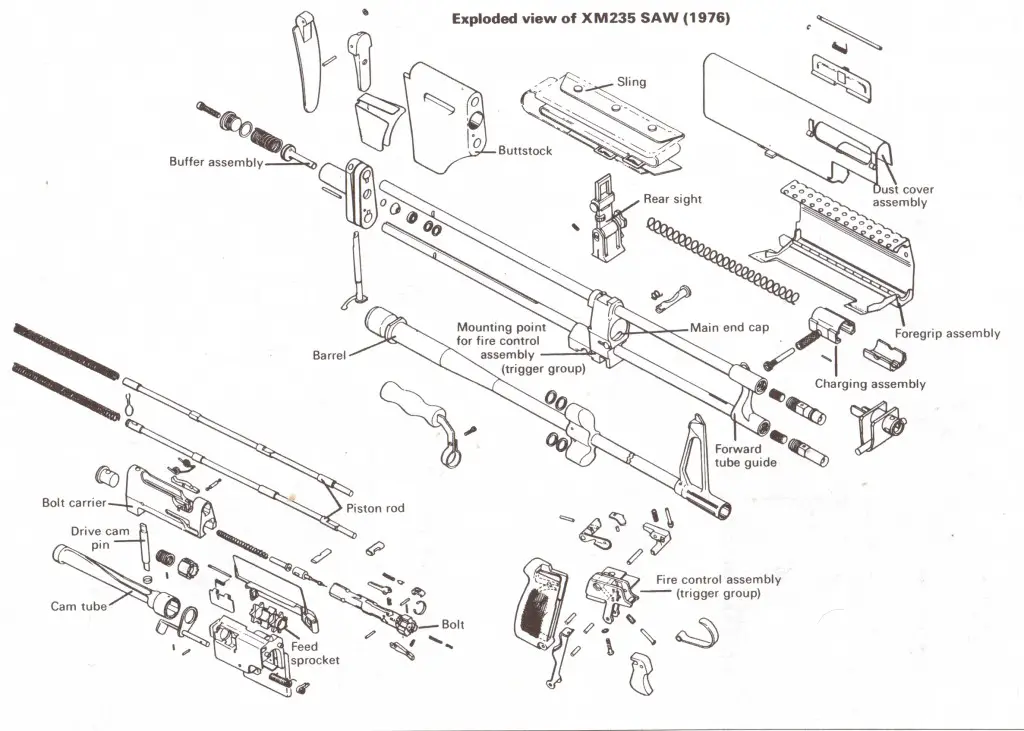

The XM235 had been developed by a dedicated team at Rodman, led by Curtis D. Johnson and including at least 7 more dedicated engineers, who all signed on to the patent US # 3,999,461 on the gun (USPTO link) (Google Patents link).

One of the controls also fared well at the tests: the FN Minimi was as reliable as the best of the 6mm guns, and more so than the H&K. It used then-special FN ammo (SS109) which didn’t interchange with the riflemen’s 1:12 M16s. Nobody liked the HB M16 as a SAW.

At this point, the Army dropped the idea of the 6mm round. It not only complicated Army logistics to have a third entire caliber, but it would be hard to sell to NATO, where American allies had already had two Yankee cartridges rammed down their throats. So the SAW was going to be 5.56mm. How were they going to get the 5.56 to perform “beyond 800m” as the spec had said? They weren’t. So the new spec was “up to 800m.”

This set the Army up for the next round of testing, but they needed someone to produce the XM235. The prototype that so impressed everyone at DT/OT1 was handbuilt, and the Rodman guys weren’t manufacturing or production engineers. The answer seemed obvious: let Maremont and Philco, uh, Ford Aerospace, bid on producing the the XM235. Ford won the bid, and engineers being engineers, began improving the design even as they committed to building a couple of dozen prototypes in 5.56 for testing. The 5.56 quasi-production variant of the XM235 was the XM248.

Let’s take a look at the XM235 technically and see why it was so admired at the time. We’ll push back Ford’s many changes that produced the XM248 till tomorrow. (This post is already 1500 words long!)

The Rodman engineers began with a clean slate and the understanding that, other things being equal, automatic weapons firing bursts had always been less accurate than rifles firing single aimed shots. This wasn’t invariably a bad thing, as it allowed for the natural dispersion of a burst to “correct” in a way for a gunner’s aiming error, but it was terribly wasteful of ammunition.

Engineers being engineers, they asked why the automatic guns were less accurate, and they concluded that several things degraded the accuracy of automatic weapons:

- Parts of the mechanism were moving whilst bullets were still in the barrel.

- Whether operated by recoil or gas, the operating mechanism reflected excess energy back into the weapon, what the developers called “high restitution” from rebounding parts.

- Extant light machinegun designs had overly high rates of fire (650 to 1000 rpm).

- Peak recoil was high (500-1200 foot/pounds – 2,200-5,300 N).

Those items, taken together, degraded accuracy. So the characteristics sought in the 235 design were:

- A long motion of recoiling parts.

- A soft cycle without the hammering of buffers on stops often seen in LMGs.

- Rate of fire reduced to 500 rpm, little more than half that of an M16A1 with M193 ammo loaded with WC846 powder.

- Reduced recoil impulse (to 200 lb-ft) and reduced recoil effects on muzzle movement by careful placement and design of stock and grips, gas system, and so forth.

- A change in belt handling to reduce the stop-and-go motion of the belt

- Placing parts that induced motion inimical to accuracy (the belt feed, for instance) close to the weapon’s center of gravity, to reduce the moments these parts induced for a given force.

In addition, the engineers wanted to design a weapon with world-class reliability and maintainability. They wanted it to be made up of field replaceable modules, and readily field-stripped in 10 seconds. They wanted to reduce the parts count relative to the M60 (they cut the parts count by 40%).

The receiver was extremely unconventional. What looks like the receiver in pictures is a sheet metal cover with no structural function. The fore-end likewise is a simple stamped cover. The actual receiver comprises two long tubes, a forward end cap that joins the tubes to the barrel, and an aft end cap that contains a sophisticated hydraulic buffer. The bolt carrier rides between the tubes, and connects to upper and lower pistons and springs, which ride inside the receiver tubes (which do double duty as gas tubes). The bolt carrier also contains, of course, the bolt, which has three lugs like an AK bolt, dual extractors and a plunger ejector.

The bolt carrier also drives, in its long travels, a rotating cam tube that turns a feed sprocket that lifts the feed belt with rotary action. There is no reversing or reciprocating motion orthogonal to the direction of fire — unlike the classic MG34/MG42-inspired feed tray cover, or that of the Browning or Maxim for that matter.

A spring-loaded firing pin rode in the bolt, and the fire control and related switchgear were contained in the pistol grip. In order to hang the belt container exactly on the center of gravity, the pistol grip was also hung on the center of gravity front-to-rear but offset to the right. Several effects came packed with this: moments of any operator input on the pistol grip were reduced, because it was at an arm of nearly zero, increasing accuracy; the weapon gave the gunner unprecedented control; and the weapon required right-handed operation. The Army liked the former two, but were keenly aware that about 10% of troops are left-handed. The weapon also required left-handed operation because it was, in effect, a bullpup design. Previous Army skittishness about bullpup safety may have been reduced by measures taken to prevent an out-of-battery firing, and the bolt’s location within the heavy carrier and the solid sheet-metal receiver cover.

Ford Aerospace had the order to produce 18 production-ready XM248s, which were to be the XM235 in 5..56 (instead of the abandoned 6.0×45) with a few improvements. (In the end, they’d make two versions). The improved XM235 was the XM248. Then, post-Vietnam budget cuts savaged the SAW program. The money was there to make the XM248s, but not to test them. The XM235 had been set to compete against the Minimi — if the Minimi could be lightened enough to meet spec — and a couple of USMC-sponsored heavy-barrel M16s (again). That is, in fact, where the 1977 11th Edition of Small Arms of the World left the competition: uncertain, and potentially cancelled entirely. The budget for the competition had been cut so much that the Army had no money for testing the 18 5.56mm XM248s that Ford delivered under their contract, or anything else. IF FN was going to lighten the Minimi, they’d have to do it on their own — contract money wasn’t forthcoming. H&K was fuming on the sidelines, believing their HK23 had been unfairly DQ’d. And Army squads still had, by MTOE, an “automatic rifleman” whose only concession to firepower was a tinny little bipod for his M16A1; alternatively, they could carry a heavy M60 and its heavy ammunition along.

Tune in tomorrow as the XM235 emerges from its Ford chrysalis as the XM248 — and becomes the most advanced light machine gun the US Army ever rejected.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

3 thoughts on “The SAWs that never WAS: Part 2, the XM-248’s forerunner, XM235”

BTW, what is your opinion of the FG-42?

From what I’ve seen, it seems superior to both Garand and M14. And even seems somewhat controllable on fully-automatic fire, I imagine someone who knew what they were doing could perhaps, with the addition of a belt feed make a reliable and useful light machine gun.

Here’s a modern day German replica. Some Texas guys make a semi-auto only replica of the same model too, ForgottenWeapons tested it.

http://www.youtube.com/watch?v=ISKnl1OnI9Y

Actually this was the genesis of the US M60. The idea was to combine the action of the FG42 with the belt feed of the MG-42 (almost all subsequent MGs copy the MG42 feed mechanism, except for Russian ones that need to pluck a rimmed case out of a belt to the rear).

The M60 designers didn’t notice that the FG42 mechanism is copied from the Lewis Gun. (Seriously, find disassembled pictures of each one’s bolt and operating rod!). The FG fires from the closed bolt in semi-auto and open bolt in full-auto, a very elegant combination to increase semi accuracy and full-auto cooling. However, its accuracy is only so-so, not in the class of a rack grade M1, M14 or K90k for that matter.

It is classically German: overengineered and complicated. And smooth running and good-looking. Kind of like the BMW 633csi I once had (I think I put the mechanic’s kid through Yale keeping it running).

The FG42 is something I see as a great modernization of the BAR concept rather than a competitor for the battle rifle. It’s definitely not in the class of AR-10 or FAL from an infantryman’s viewpoint. But those had ten years more for development!

The Texas outfit is SMG Guns, and last year I got the paperwork to order an FG42 but didn’t follow through as the bottom fell out of my industry (and, there are so many options on the SMG order form you almost have to be an FG42 variations expert to know what you want!)

I believe the German copy is of a different version of FG42 and it’s dimensionally close to the original, so that ATF would not allow it to be imported lest the criminal element use its vast stocks of FG42 parts to convert to full-auto.

Yeah. It also costs something like €30,000

If I ever won a lottery, say €10 000 000, I’d probably buy one. And also their MP38 replica. With that kind of money, one could start their own firearms museum so the may-issue collector extemption would not be a problem.

What makes the accuracy worse, I wonder? The need for reliable full-auto functioning?