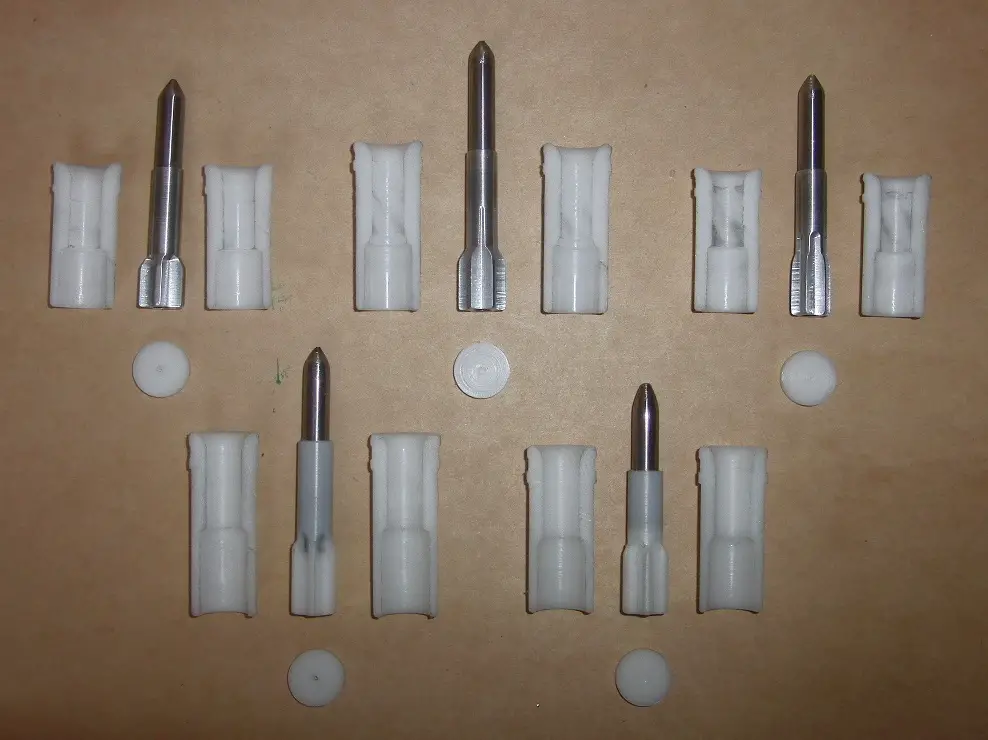

The following very brief video (00:35) shows some proposed designs for subcaliber fin-stabilized rounds for 12-gage shotgun. Previous attempts at discarding-sabot ammunition failed because the sabot failed to separate, yielding an unstable, tumbling (and velocity- and energy-shedding) projectile.

In an attempt to work around the sabot problem, he’s discarded (no pun intended) the sabot and instead increased the fin thickness, making the fins bore-riders. These new rounds haven’t been fired yet, but we can pretty confidently predict weak results.

The previous rounds were made in many different types (here’s the project’s imgur page) but generally produced disappointing results. It’s unlikely the low-pressure environment in a shotgun can produce enough velocity to make these projectiles effective at any range, and it’s even less likely that the various resin and nylon parts can either produce a bore seal and sufficient velocity, or accuracy.

There’s a lot of work in these hand-machined parts. Here’s a video look at what goes into manufacturing a penetrator from a stainless-steel bolt.

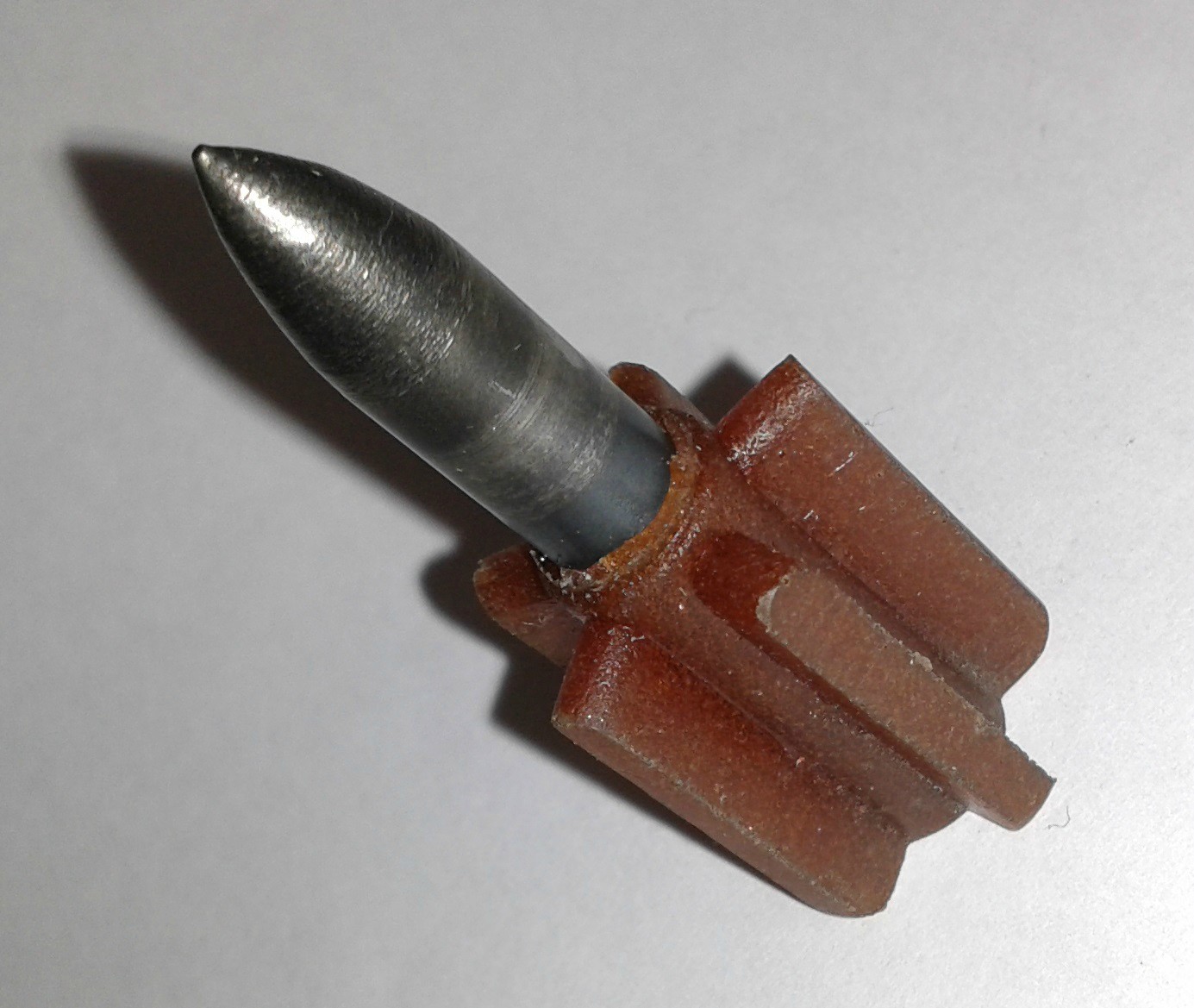

And here’s a resin-cast version of the fin-set part, which was intended to replace the white delrin parts.

While we admire the guy’s ingenuity and diligence, his aerodynamic savvy is not in the same league. Pro tip: learn what a Reynolds Number is, and you’ll understand why it’s working against you here.

Also, there’s a ton of literature on sabot separation, if one seeks it. Trial and error is great, but the reason we can sustain great efforts as a species is because today’s trial stands upon the lessons learnt from yesterday’s.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

20 thoughts on “Homemade Shotgun Sabot Ammo”

When I can get some free time to get back to work on the bullet molds, I have some ideas as to shotgun slugs. My Mossberg “musket” has never fired a shotshell…

The US Army’s arsenals and contractors have done a lot of research on stabilizing projectiles from non-rifled barrels, much of it freely available for download on http://www.dtic.mil.

Wouldn’t HEAT make more sense? IIRC, I recall seeing some in a documentary somewhere. Boys in green have all the best toys…

GMTA.

Of course, from a 12 ga., it would be a HEAP round…

One wonders if something could be done with tannerite in that regard, without blowing up in battery.

A HEAT round’s effectiveness (penetration) is largely proportional to it’s diameter-one of the reasons behind the switch on NATO MBTs from the excellent 105mm rifled L7 to the Rheinmetall 120mm smoothbore, the other being APDSFS stabilizing better in smoothbore barrels. WWII HEAT rounds typically penetrated ~250% of their diameter. A 12ga round is roughly 0.729″ in outside diameter, suggesting a total penetration of ~1.8225″ under ideal conditions. The small mass of copper (or other ductile alloy, perhaps aluminum) for the explosively formed penetrator probably would not be enough to have decent armor penetrating characteristics either.

That said, it’d be pretty neat to make just to see how well it performs and get the oddly shaped rounds to chamber reliably.

If you could fabricate plastic explosive and an impact-delay fuze, HESH might be easier to make and less likely to explode in your bore-not that I have any first hand experience blowing things up with C4/RDX/etc.

Y.

That’d be actually pretty good. Though I wonder what would be the effect on the other side of the armor. Probably nothing to write home about.

The decidedly elephantine PTRS rifles can only penetrate 40 mms at 100 m.., however, even a slow 14.5 mm projectile bouncing inside a tank has got to be a very nasty experience.

That is why the Germans added armor skirts to Pz III and IV. 14.5 could penetrate 1 side.

Aesop, James Forsth is the godfather of tinkering along these lines. He was shooting his exploding bullets at fuzzy-wuzzies in the 1850s, as discussed in his, “The Sporting Rifle and it’s Projectiles.”

I got a copy from google books a few years back. He discusses “Forsyth compound” consisting of (IIRC) mercury fulminate, antimony sulfate, and a third ingredient that escapes me (basically priming compound!!!), that in theory explodes only after sufficient penetration into the target. The Afghans protested with one of their main objections being that exploding bullets deprived them of one of their main sources of lead to fire back!

Greener’s “The Gun and it’s Development” has diagrams of many styles of exploding bullets between 12 and 4 bore. Ross Seyfried in some late 90s issues of Black Powder Hunting details whacking some water buff with exploding 8 and 4-bore shells. I’ve hunted with a big 4 on a few occasions (elephant and water buffalo) but have never been crazy enough to tempt fate with an in bore detonation. It seems the late 1800s hunting literature described the jacketed “high” velocity smokeless rounds of the 1890s to be just as or more lethal without the attendant risk and so they were promptly dropped from their already micro-niche.

Also from memory, I believe .25 ounce is the limit for explosive compound in a projectile in the US without either a license or a $200 tax per round, which is why some 50BMG ammo slides by.

I’ve got an idea that I’ve been tumbling in my head. Paneling nails. They’re hard as a whores heart and are just a little long to fit in the AA12 wads I have. I was thinking of using silcone caulk to “cement” them into a slug of sorts, like a stack on rods (think facia) which on impact would allow the penetrators to seperate and spall. Some hurdles that I can think of are the weight, the payload would be a little on the light side, but that would make for velocity increase. I might try JB weld and hot glue as alternate bonding, too.

Range would be pretty short, this is no Pak40. But it’s expedient and cheap, and a lot quicker to produce than turning down each projectile.

Anything made for masonry or wood is going to fail against steel plate – throughout the series of tests there were several instances of a good head-on hit on the plate which failed to penetrate due to the core being made of mild steel.

You mean I can’t just bang out some aluminum darts on my table sander, stick em in an epoxy mold, and go to town? Well sh*t. There goes my weekend.

It is unclear from their Imgur page whether they are considering body armor or vehicle armor. The body armor issue was solved long ago, for shorter ranges. And, aside, when did the Frag-12 development die or go dark?

For the purposes of these informal tests, “armor” is steel plate of no particular hardness.

There are commercial sabots for shotgun slugs. They bring the velocity up to around 1800 ft./sec. I wonder if drilling a central hole with a lathe and inserting in a Tungsten rod would make a decent penetrater. The theory being the slug would go splat against something hard and the rod would continue.

This would also be a viable option, but most people don’t have rifled bores on their shotguns – I’m looking for something that will work in smooth bores, hence the fin stabilization.

Why not save the sabot work and tungsten for something with a bit more oomph? Get a bayonet for the shotgun, or modify a soda can for the Can/Grenade Cannon….

“Why not save the sabot work and tungsten for something with a bit more oomph? Get a bayonet for the shotgun, or modify a soda can for the Can/Grenade Cannon….”

Cause making things that blow up just cries out for a Darwin Award. I can send you some recipes if you like.

Could you send them to the guys with the shotguns instead? I prefer my boom-booms well tested for reliability, and since I’m one of those rabid fearsome dangerous terroristic clinging bitter Creationists, a DA would be wasted on me. Also, I’m not all that keen on showing up at Bema Judgement early through showing poor judgement, and worse chemistry skills. Anyway, such things are Verboten here, seeing as how only Government should be trusted with possession and use of firearms and explosives. Much safer than letting irresponsible folks get their hands on that stuff, I mean, where would we be if everyone started invading each other and blowing each other up up and away? Oh, wait. Never mind. So, how can I make field expedient fuming nitric acid? I want to etch the Eu flag and the complete score of “Ode to Joy” on my gruel bowl.

Hi there, I’m the actual manufacturer of these darts and occasional reader of your blog, didn’t expect to be featured here! In response to some of your points:

>While we admire the guy’s ingenuity and diligence, his aerodynamic savvy is not in the same league.

I’ll admit I’m no aerodynamicist, but I have based my darts so far on one basic principle, center of gravity ahead of center of mass: http://www.mrphome.net/mrp/Analyzing_the_CG_vs_CP.html – built on this principle, a projectile should always point head first. I believe that any time you see tumbling in the testing is due to the fact that the fins have either been destroyed by the acceleration in the barrel, or that incorrect sabot separation has caused the projectile to yaw.

Take one thing into consideration, I’m just some guy pissing around with a lathe, this is not a commercial concern. I know for example that making a sabot with four “petals ” will result in a cleaner separation than just two, but that means more work and more complication for the tester to implement my ideas – I’m not present when the things are loaded up so they are not necessarily run to my “specifications” – for example in his last test Taofledermaus taped the sabots together, in some cases this obviously ruined the separation. The feedback loop is quite tenuous due to geography, but soon I hope to have my own 12 gauge available in order to carry out my own testing. Not making excuses for myself here though, many of the rounds were based more on “I hope this should work” rather than “I’ve done the math” – but I’m learning, and I hope these latest rounds should be a success.

>These new rounds haven’t been fired yet, but we can pretty confidently predict weak results.

Clearly you do not share my level of confidence the bore-riding sabotless idea was already tested by Demolition Ranch here: https://www.youtube.com/watch?v=qZYnFC__pOk&feature=player_detailpage#t=56 and they seemed to do pretty well in terms of flying nose first. Unfortunately DR doesn’t use high speed cameras so it’s difficult to evaluate the actual path of the projectile.

the bore-riding sabotless idea was already tested by Demolition Ranch here: https://www.youtube.com/watch?v=qZYnFC__pOk&feature=player_detailpage#t=56 and they seemed to do pretty well in terms of flying nose first. Unfortunately DR doesn’t use high speed cameras so it’s difficult to evaluate the actual path of the projectile.

There’s a lot of restrictive parameters here, the projectile can’t be too long, can’t be too heavy or too light, and it has to survive the massive forces as it accelerates in the barrel – and of course, it has to be relatively easy to make – so inevitably there has to be compromise in the design.

>It’s unlikely the low-pressure environment in a shotgun can produce enough velocity to make these projectiles effective at any range

I disagree, look at the Russian 9 x 39mm cartridge: http://en.wikipedia.org/wiki/9%C3%9739mm

It fires a steel cored bullet of around 250 grains below the speed of sound and claims the following performance:

SP-6 (7N9) – The SP-6 (СП-6) was developed by Yuri Frolov. It has a hardened metal armor piercing core. It can penetrate 2 mm (0.079 in) of steel at 500 meters or 6 mm (0.24 in)of steel, 2.8 mm (0.11 in) of titanium or 30 layers of Kevlar at 200 meters. At 100 meters it penetrates 8 mm (0.31 in) of steel, while retaining enough power to neutralize a soft target behind it.

This is one of my “objectives” so to speak – to show that the humble shotgun has a lot more potential than what many people believe, and to add to its versatility.

>and it’s even less likely that the various resin and nylon parts can either produce a bore seal and sufficient velocity, or accuracy.

The shotgun wad is what is providing the seal. In terms of accuracy, it will obviously never be as accurate as a rifle, but I would be happy to see a 6 inch group at 50 yards – I believe that if the projectile is consistently made, this is achievable.

Talk is cheap, we’ll see how these rounds actually perform in the field, but I’m pretty optimistic.

Thanks for the interest in my “work” in the meantime, I enjoy your blog.

Thanks for your great comment, which includes a lot of tech detail that is not in the original post. If I can get to it today I’ll make sure that the post is edited to draw readers’ eyes to the comment.

The principle you’re referring to is “center of gravity ahead of center of mass.” Unfortunately while I know some good aero texts for non-experts they are all oriented towards pilots and aircraft designers (yes, we have amateur aircraft designers. And some of them are damned good, based on their results, so you don’t need a blessing from MIT to split the air wisely). I don’t know of one that handles exterior ballistics of projectiles as well.

If you wish I would be happy to put together an illustrated writeup tracking my progress so far, it would be good from my point of view to be able to detail the designs and go into the justifications behind certain features and design elements which I used – the youtube comment section is not exactly a great forum for this purpose.