We discussed toggle-locking recently. This obsolescent technology was very strong in the early 20th Century; its most important deployed weapons were the German P.08 and other Luger pistols, and the Maxim machine guns. In the comments to that post, Max Popenker of the indispensable world.guns.ru noted a few examples of toggle locks we forgot. And we’re not sure if we really got the reasoning behind toggle-locking across; it has some strong engineering benefits, and only died out because of its high cost of manufacturing using mid-20th Century processes. So in this article, we’ll look at the toggles we missed, look at “why would a designer use it,” and “what killed it,” and throw out some wild, futuristic speculation.

Toggles we missed

We thought our overview of toggle locked firearms was pretty comprehensive. Any time we think that, of course, someone sets us straight. In this case it was Maxim Popenker of world.guns.ru website. (Hey, Max, are you named after the machine gun? Like Larry Correia’s fictional character Owen Z. Pitt?) Here’s the guns Max mentions in his comment to the other post:

- The Swiss Lmg.25 by Rudolf Furrer.

- The Lmg.Pist 41/44 from same designer.

- the line of semi-automatic rifles and carbines designed with a side-opening, horizontal toggle by Karl Heinemann of Rheinmetall-Borsig between the wars.

- some modern Russian small-bore biathlon rifles.

Let’s expound on these finds of Max’s for a bit.

Furrer Designs

The Furrers are best-known of these little-known guns: the tallest of the midgets, as it were. Max considers the Furrers to be “excellent examples of fine Swiss over-engineering,” and since their designer was a Swiss officer, an engineer, and the superintendent of the state arsenal Waffenfabrik Bern, they come by that honestly. Max’s descriptions of the two systems and their developmental and service history (linked above) is great, so we’ll just have a few comments.

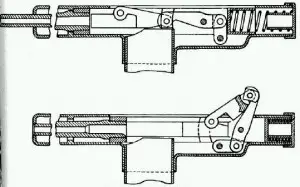

The Furrer short-recoil design uses the mechanical relationship between three links, rather than two links cammed by a surface on the stationary frame as in the Borchardt/Luger system, to unlock and open the breech. This diagram from Max’s site shows the LMG action; the SMG is exactly the same, but is a mirror image.

This is a Furrer SMG prototype, showing much more Luger kinship than the LMG of only a few years later, or the later Furrer production SMG. Note we’re looking at it from underneath, but it’s oriented like that overhead diagram of the LMG! Image: Enfield Pattern Room, Leeds via Forgotten Weapons.com

One unusual feature of the Furrer SMG is that the box magazine loads from the right, and the gun ejects and toggle opens to the left. Meanwhile, the LMG is the slightly more conventional other way ’round. Why this is is anybody’s guess, but even very early Furrer pistol-caliber guns had this layout, like this circa-1919 prototype, which uses a Luger toggle action rather than the coming Furrer system, featured at Forgotten Weapons. Switzerland was the first nation in the world to adopt the Luger in 1900, and the last to use it as a frontline service pistol (circa 1947) when they replaced it with the excellent SIG; Swiss Lugers were made at Waffenfabrik Bern, home of Furrer (the man and the machine alike). (Indeed, the Swiss Luger tooling was the only set to survive the war, and was used by Mauser to produce some continuation Lugers in the mid-70s or so).

Heinemann Design

Numerous Heinemanns seem to have been made, but they were never adopted anywhere, and they don’t seem to have been made in quantity, although the surviving guns are well built and don’t have the “factory mule” look of tool-room guns.

As Max noted, the gun was tested by the USA among the dozen or so designs that were wrung out in the interwar years, before the 1936 decision to go with the Garand for the US Rifle M1. We’d call what Max calls “7mm Pedersen” a .276 Pedersen here, but we can’t expect a sophisticated European like Max to still express things in lines and arshins like we do (grin). There are also surviving examples in 7.92mm, the German standard caliber that was also widely used by other European nations, including Poland, Yugoslavia, and the Czechoslovak Republic.

The Heinemann combined the muzzle-cap gas system of the Swedish Bang with a toggle-lock that opened on the right of the gun. The detachable box magazine fitted into the receiver on the left. The design appears to be somewhat exposed and fiddly, not entirely what you’d want for mud-crawling infantrymen.

Compare the toggle of the Pedersen, which is shown to good effect in this web article.

The modern Russian biathlon rifle

A Russian lady biathlete sighting-in her Izmash before World Cup competition in Maine, USA 2011. Germans with Fortner/Anschutzes won. Crowley photo.

Max noted that “some modern biathlon small-bore rifles still use manually operated toggle lock action (also with horizontal toggle).” Indeed, the lock resembles a slicker version of the Heineman, manually operated so it can be run by fingers without shifting the shooting hand. These guns were used by biathlon competitors from Soviet block states like East Germany and the former Soviet Union, and they inspired West German Gold Medalist Peter Angerer to ask gunsmith Peter Fortner for something as fast, which produced the Fortner/Anschutz action, a finger-fast straight pull that is not a toggle action.

This Izmash biathlon rifle sells for less than half the cost of Fortner/Anschutz, and it’s just as fast and accurate. Izmash not only makes the biathlon guns, but they make the same action in an equally accurate sporting gun, with the lightning-fast toggle action and a five-shot magazine.

These guns are noted, not just for the lightning speed of the toggle action, but for fantastic triggers and great accuracy. Here’s a review of a sporter version. Unfortunately they’ve been available in the US market only intermittently, and they’re as expensive as any European precision target gun. RWC is, according to their website, the current importer.

If you want to build your own, Primary Weapons Systems in the USA makes a receiver and bolt assembly on this toggle/overcenter principle that is a locked-breech manually-operated cousin to its well-known line of 10-22 locks.

The PWS action is available built into guns as well, but it’s also popular for suppressed .22s for hunting, plinking, or other purposes. It’s nearly as fast as the semi, and much more tolerant of ammo and backpressure variations.

Why toggle?

It makes sense when you consider the alternatives. It allows a very light weight of reciprocating parts. It allows a very positive lock. It makes for easy action: very little energy is required to unlock it, and very little to close it again, thanks in part to the light weight, and thanks in part to the overcenter positive lock. It is possible to design so as to guarantee out-of-battery firing can’t happen. (True, Browning had ways of doing this, too).

Finally, a toggle lock has a high strength to weight ratio. Given equivalent metallurgy, it’s possible to build a toggle-locked gun with a lighter weight than, say, a tipping barrel Browning handgun or tipping bolt rifle.

So, what killed the toggle?

Despite those Russian biathlon guns, which might be the only toggle-locked weapons still produced, this once-popular locking system has gone the way of, if not the dodo, say, the giant panda — an endangered species kept alive mostly by human curiosity and effort. So what killed it off?

There were two things: costs, and adaptation to a range of ammunition. To make a Luger or a Maxim lock, in 1913, required a great deal of effort and precision machinery, and the key software for that machinery was in a trained, experienced human mind. In 2013 tool and die makers are rarer and much, much, more valuable commodities than they were 100 years ago; the market has rewarded manufacturing simplicity, which is why lots of people are carrying guns made on CNC machines and injection-molding machinery (for plastics and certain metals). A gun factory floor in 1945 looked a lot like the DWM plant in 1913: lots of horizontal mills, each tooled for one operation; lots of horizontal shapers, a machine whose versatility and simple tooling made it indispensable, but whose versatility compares to that of a CNC machining center, that can do something radically different with some new tool quills and a program download.

These new-style machines have shifted much of the problem-solving of parts manufacture from the shop floor to the engineer’s cubicle, and he in turn has considerable software assistance.

But the shop floor for 2013 isn’t going to look like the shop floor of 2033, let alone 2113. That gives the toggle — and even the Luger — some hope for a comeback.

Before we discuss that, though, we need to talk about the other reason, besides manufacturing costs, that the toggle lock has fallen into disuse. That’s that a traditional recoil-operated toggle lock is designed, calculated, substantiated, and regulated for a specific round of ammunition. This obviously doesn’t affect manually-operated toggles, like the excellent Izmash biathlon and sporting rifles. And it would be possible for a gas-operated toggle like Heinemann’s to adapt to a wider range of ammo than a recoil-operated weapon. But a toggle like the Luger is only going to have one sweet spot (and Lugers are, in fact, notoriously discriminating about ammunition). Most shooters these days like to have a range of bullet weights and velocities on hand. It’s harder to do with a toggle than with Browning’s tipping barrel, which is why the Browning system has driven the toggle and most of its other competitors into retirement in the pistol world, the last real refuge of recoil operation.

Hope for a comeback?

We implied, above, that manufacturing in this century is changing faster than manugacturing did last century, and that this offers hope for a comeback. For instance, CNC makes previously uneconomical manufactures economical, whether deployed in a traditional, subtractive manufacturing process like milling, or a 21st-century additive process like selective laser sintering. (SLS is very expensive right now, but the key technologies go off-patent in 2014).

CNC also allows rapid, software-driven retooling, and thereby makes short manufacturing runs economical.

And then, a lot of the effort in building that 1913 DWM Luger was hands-on hand craftsmanship.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

2 thoughts on “Toggles II: Some we missed, and why toggles?”

Ok guys,

you summoned me – here I am again 😉

First of all, according to my dad, I was named after fictional Sci-Fi hero from the book that hit shelves of Soviet bookshops in 1971.

And, while we are on it, I’m also a fan of Larry Correia. MHI rules! 😉

speaking on toggle lock, my own experience with Luger pistol gives me following idea: toggle lock sucks because moving parts are LIGHT. This is especially true for pistols

They have little inertia to spare under adverse conditions, and FTF and FTE are most frequent problems with Luger that is dirty or not properly oiled.

It is solved with Furrer system, where barrel mass is used to control the movement of the bolt through its entire cycle. But I do not think that it is practically applicable to pistols due to complexity

With rifles, there is another issue – the length of the high-stressed receiver (between the breech face and rear toggle axis) is rather long, making it heavier (and thus more expensive) than could be made with front-locking systems. Toggle links and joints also are high-stress parts that need to be solidly and precision made, further adding to the weight and the cost

Basically, that’s why most modern rifles use front locking rotary bolts – it allows for relatively unstressed receivers, which can me made light and more or less cheap

that’s my 2 cents, guys 😉

PS Just in case, NRA museum has fairy good set of Haineman carbine photos on their web site here: http://www.nramuseum.com/the-museum/the-galleries/ever-vigilant/case-61-the-great-inventors/heineman-experimental-prototype-semi-automatic-carbine.aspx

Interesting, thanks for the link.

As far as Larry goes, he might never have written another word but I’d be a fan forever for: “HK. Because you suck. And we hate you.” I do enjoy the MHI series. I haven’t been able to warm up to the Dead Six stories, and perhaps it’s because the ones with monsters are more believable, and I’m less critical of tactics used on monsters. Not ever fighting them, myself.

Max, I think the major reasons the receiver can be made light and cheap are that the Johnson/Stoner multilug bolt (1) gives better balance of locking area across the bolt, so there’s less torsion and shear inside the bolt for a given locking area; (2) reduces the required diameter of the locking-lug area of the bolt; and (3), this is the big one, locks not into the receiver but directly into a barrel extension, which means the connection to the receiver can be much lower stress… especially in a gas gun where the barrel is stationary.

In the AK, the trunnion serves some of the function of a barrel extension, allowing the receiver to be a simple piece of folded sheet metal (for all but second model, milled-receiver AKs, of course). Just a different take on the same engineering problem, how to manufacture a whole lot of rifles cheaply and rapidly.

There’s a good picture of Johnson bolt and barrel from the extension end (Johnson termed it a “barrel collar”) at this link:

http://www.practicallyshooting.com/m1941-johnson-semiauto-rifle-part-1-history/

The rotating bolt, of course, can easily be contained inside a receiver, as in the M16, and even shrouded in a heavy bolt carrier like the AK, which helps keep dirt out of the weapon. A toggle can’t really be contained like that… it needs space to swing out, somewhere. Or a big, boxy receiver (Maxim).