Because the XM248 segment of the story is taking longer than we had hoped, we’re going to go for a practical first down again (an American football analogy, for our overseas readers: we’re going to do something easy, but possible, instead of something extremely difficult). As we’ve been immersed in the surprisingly lively RDT&E world of the 1970s, where weapons systems with roots as far back as WWII and Korea were being uprooted by new technology, we began to wonder, what’s going on today?

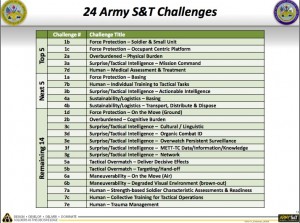

And in the world of small arms, the answer is, surprisingly little. The Army is somewhat satisfied with the weapons that they field now. This is partly because the current suite of weapons is pretty good. It’s also because the Army has other priorities that are higher. Army leaders have said that their problem areas for science and technology are as shown in the slide.

You’ll notice that most of these have no bearing on small arms development. They’re all very serious problems, but with one exception, tinkering with guns isn’t going to solve any of, say, the top ten.

You’ll notice that most of these have no bearing on small arms development. They’re all very serious problems, but with one exception, tinkering with guns isn’t going to solve any of, say, the top ten.

The exception, the place where small arms is going next, is weight reduction. This is nothing new: for 4,000 years infantrymen have bitched about their burden, and for 4,000 years commanders have admitted that the grunts have a point but have done little to alleviate the problem.

There’s a dynamic at work here: when advances reduce the burden, new gear gets stacked on the rifleman (as it did on the fusilier, musketeer, arqebusier, pikeman, or hoplite in days of yore). If the command doesn’t replace the 20 pounds’ respite that science and procurement brought you, the GI himself will, usually with ammunition.

What sort of technology will reduce weapons weight?

The last time it was successfully done, it was done by applying aerospace technology to weapons design. We refer, of course, to the crusade of the original ArmaLite from its Hollywood offices and later Costa Mesa plant, during the long pregnancy of the Space Age in the 1950s. Stoner, Sullivan et. al. drafted a variety of industrial materials and processes for guns that had been little used in the industry before, and never used explicitly for weight reduction as an initial design objective.

It was radical then, but it’s old hat now. The space age technology of 1960 — forged 7075 aluminum alloy and fiberglass, later molded Fiberite® plastic — is now not too exciting. Even the exotic material of 1960, the titanium structure of the secret A-12 spyplane, is now much more widely used. A few things that are likely to see more use in the years ahead:

- Aluminum-lithium alloys. Used in F-15 wing skins and Airbus 380 skins. May be too light for gun structures without new processes.

- Aluminum-scandium alloys. These are already showing up in lightweight pistols.

- Titanium alloys. These have come downmarket — and small arms systems have gotten so expensive — to be within reach. However, Scandium alloys approach Ti alloy strength, and are more easily machined and welded.

- Carbon-fiber and carbon-carbon structures. These could reduce the weight of stocks by 50%. ATK, which is no stranger to small arms, has achieved 20-40% reductions by redesigning metallic aerospace structures in carbon composites.

There are even more exotic materials on the horizon. Nanomaterials in particular offer benefits that will probably require complete systems redesign to be fully exploited. Indeed, they’ll probably require new basic research in the nanoscale dynamics of the mechanism inside the gun and the projectile inside the barrel.

Materials have the potential to reduce the weight of ammunition as much as weapons. The low-hanging fruit here is polymer cases. They’re hard to do because brass does a lot more than just hold the case together; so far, plastics have failed miserably at providing the gas seal that brass case obturation does. But a polymer case would get 90% of the weight-savings benefit of true caseless ammunition. Caseless, of course, would get 100% of the potential, which is why the idea won’t die, but as everyone who’s tried to make caseless guns (notably H&K) knows, that extra 10% of potential costs you several multiples of 100% of your original effort.

Another way to reduce ammunition weight is simply to ensure that more rounds fired are hits. Future ways to improve this tend to focus on electro-optical systems, but more mechanical accuracy in the service firearm is possible — and desirable.

Finally, new manufacturing technologies make possible manufacturing with a precision previously unimaginable. Additive manufacturing processes enable the design of parts previously unimagined, including parts with blind hollows inside. (It sounds like this would weaken the part, but most loads are carried on or along surfaces).

The bottom line: we’ll see a weapon again as light as the 6.6 lb. (3 KG) M16A1. But it will have much greater capabilities.

Kevin was a former Special Forces weapons man (MOS 18B, before the 18 series, 11B with Skill Qualification Indicator of S). His focus was on weapons: their history, effects and employment. He started WeaponsMan.com in 2011 and operated it until he passed away in 2017. His work is being preserved here at the request of his family.

3 thoughts on “Where Small Arms R&D is going next”

As you point out, the surest way to improve small arms and reduce the load is to reduce the number of shots fired to achieve a hit. As I recall, the operations research that led to the M-16 found that tens of thousands of rounds were fired per casualty inflicted, because most fire was unaimed fire in the general direction of the enemy. Thus, we should field a gun that could put as many rounds down range as possible — glorified .22 rounds, to reduce recoil and weight.

Our modern optics should bring the shots-to-casualties ratio back into line, but I don’t think that’s been the case. Simply spotting your enemy seems like the biggest challenge, and I’m not sure that a muzzle flash on the next ridge it quite good enough to return aimed fire with a rifle.

That reminds me, are you planning on writing something about grenade launchers and tactics?

Great points.

Fun fact — the 5.56 in the field matches the 7.62 pretty well for lethality but gets put on target more frequently. We should probably do a post on the Swedish guy’s NDIA presentation — Per Arvidsson, I think his name was. BLUF: instant incapacitation requires a CNS hit: brain, stem, or the 1cm wide spinal cord. Even multiple center of mass hits may only cause the eventual death of the target.

GLs deserve a couple of posts — on technology and tactics. My first CT school I wound up as a GL gunner, and can explain why we used the M79 versus M203.

“The exception, the place where small arms is going next, is weight reduction. This is nothing new: for 4,000 years infantrymen have bitched about their burden, and for 4,000 years commanders have admitted that the grunts have a point but have done little to alleviate the problem.”

That is sort of true but not quite as you depict it. As reductions are made in the weight of weapons and ammunition, commanders just have the troops carry more of other things like rations, water or ammunition for the crew served weapons. This improves the capabilities of the individual and the unit – they can stay out longer and a modern squad can probably unleash as much firepower as a WW II era company – but the one thing that does not happen is for the troops to carry less weight in gear.